Method for improving the magnetic property of sintered NdFeB flaky magnets

A NdFeB, magnetic performance technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve problems such as difficult to achieve industrialization, achieve high distribution uniformity and thickness consistency, improve organizational structure and composition, Realize the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

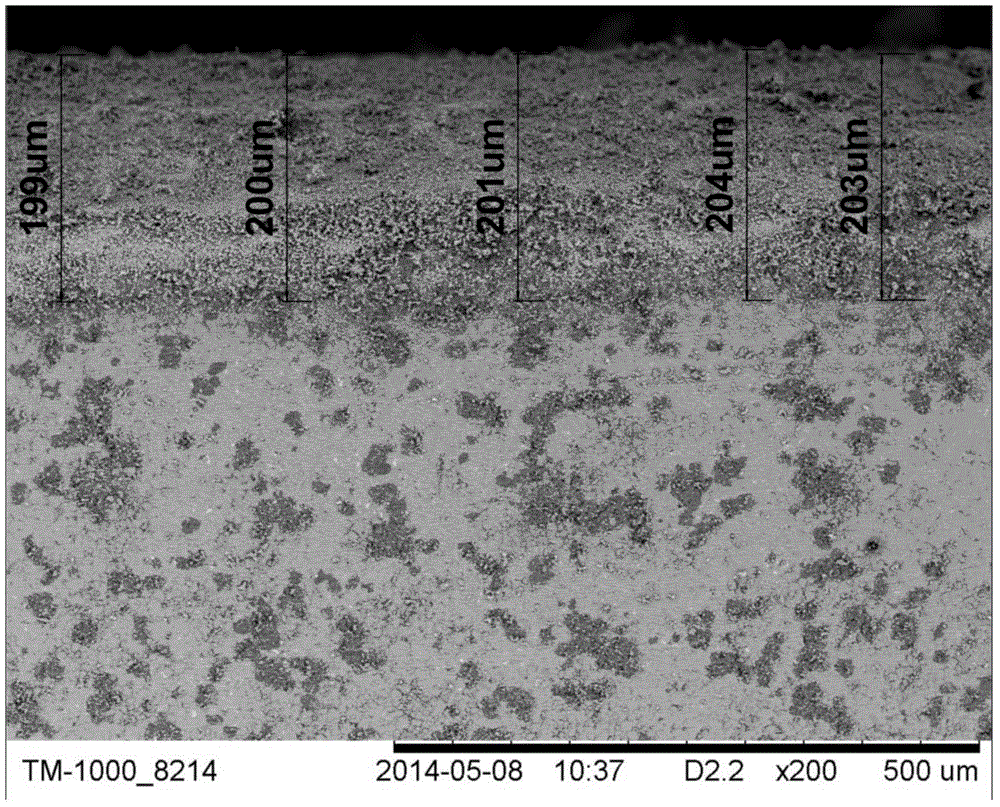

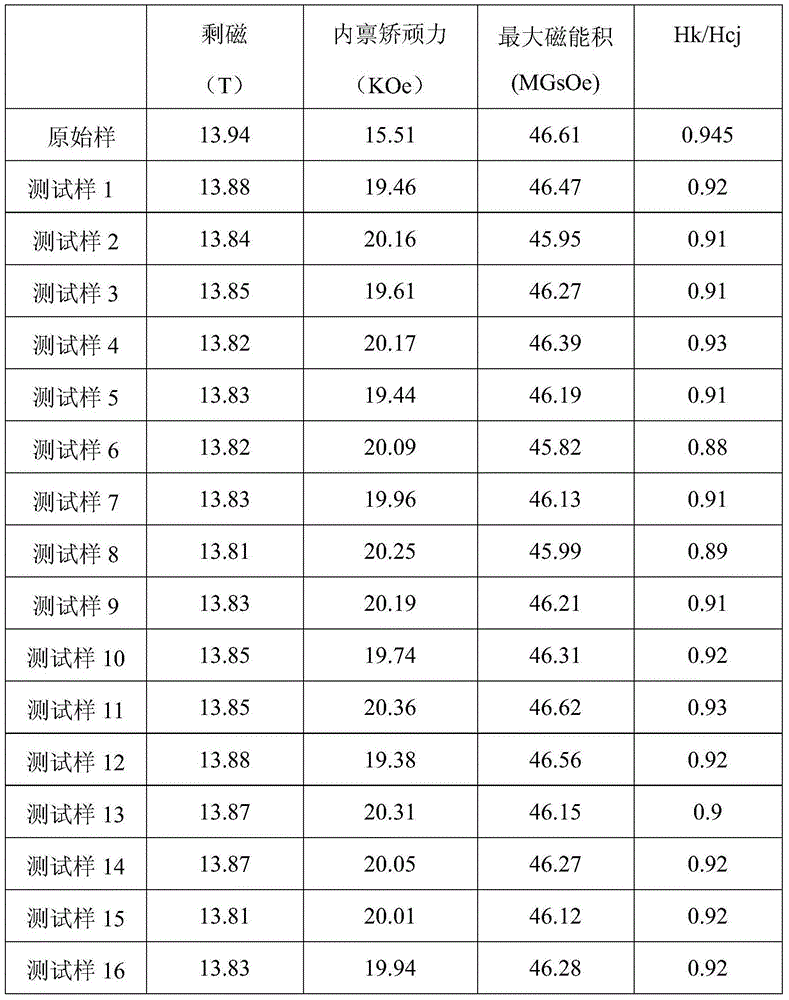

[0024] Embodiment 1: A method for improving the magnetic properties of a sintered NdFeB sheet magnet, including the following steps:

[0025] ①Prepare heavy rare earth compound powder, the heavy rare earth compound is DyF3, and the particle size of the powder is ≤10μm;

[0026] ②Disperse the heavy rare earth compound powder in anhydrous ethanol and mix it evenly to obtain a suspension. The viscosity of the anhydrous ethanol at normal temperature and pressure is 1.08mpa.s.

[0027] ③Spray the suspension uniformly on the surface of the sintered NdFeB sheet magnet to form a coating, and the sintered NdFeB sheet magnet has been subjected to surface pretreatment before spraying;

[0028] ④ Dry the sprayed sintered NdFeB thin magnets. The drying process is to keep the temperature at 80℃ for 1h. The dried sintered NdFeB thin magnets are stored in an inert gas environment;

[0029] ⑤ Put the dried sintered NdFeB sheet magnet under the pressure of 1×10 -4 In an inert gas environment of Pa, the d...

Embodiment 2

[0038] Embodiment 2: A method for improving the magnetic properties of a sintered NdFeB sheet magnet, including the following steps:

[0039] ①Prepare heavy rare earth compound powder, the heavy rare earth compound is DyF3, and the particle size of the powder is ≤10μm;

[0040] ② Disperse the heavy rare earth compound powder in a mixed solvent with a viscosity of about 4.0 mPa.s at room temperature and pressure, which is obtained by mixing absolute ethanol and ethylene glycol, and stir uniformly to obtain a suspension.

[0041] ③Spray the suspension uniformly on the surface of the sintered NdFeB sheet magnet to form a coating, and the sintered NdFeB sheet magnet has been subjected to surface pretreatment before spraying;

[0042] ④ Dry the sprayed sintered NdFeB sheet magnets. The drying process is to keep the temperature at 120°C for 1 hour. The dried NdFeB sheet magnets are stored in an inert gas environment;

[0043] ⑤ Put the dried sintered NdFeB sheet magnet under the pressure of 1...

Embodiment 3

[0049] Embodiment 3: A method for improving the magnetic properties of a sintered NdFeB sheet magnet, including the following steps:

[0050] ①Prepare heavy rare earth compound powder, the heavy rare earth compound is DyF3, and the particle size of the powder is ≤10μm;

[0051] ②Disperse the heavy rare earth compound powder in a pva solution prepared by 1788 type polyvinyl alcohol and water. The mass percentage of 1788 type polyvinyl alcohol is 7%. After mixing uniformly, a suspension is obtained. The pva solution is at room temperature. The viscosity is 26mpa.s under normal pressure.

[0052] ③Spray the suspension uniformly on the surface of the sintered NdFeB sheet magnet to form a coating, and the sintered NdFeB sheet magnet has been subjected to surface pretreatment before spraying;

[0053] ④ Dry the sprayed sintered NdFeB sheet magnets. The drying process is to keep the temperature at 120°C for 1h. The dried NdFeB sheet magnets are stored in an inert gas environment;

[0054] ⑤ P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com