Cereal color sorting control system

A control system and grain technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problems of affecting color sorting effect, high take-out rate, low color sorting rate, etc., to improve color sorting rate, reduce the take-out rate, economical and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described in detail:

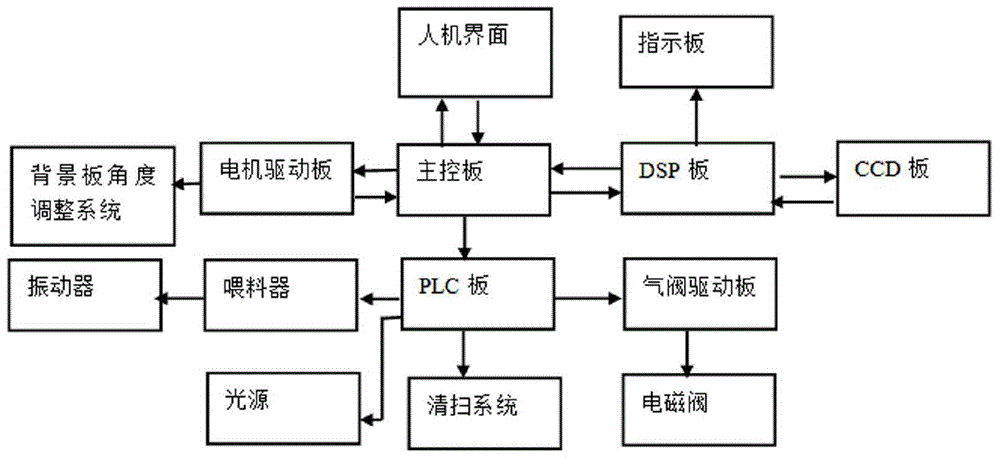

[0020] Such as figure 1 Shown, a kind of grain color sorting control system is characterized in that: comprise main control board, main control board connects man-machine interface, DSP board, motor drive board and PLC board, DSP board connects CCD board and indicator board, motor drive board Connect the angle adjustment system of the background board, the PLC board connects the feeder, the light source, the cleaning system, the air valve drive board and the motor drive board, the feeder connects to the vibrator, and the pneumatic drive board connects to the solenoid valve;

[0021] The main control board is the core of the control system of the grain color sorter. It communicates with the man-machine interface through the single-chip microcomputer to obtain control parameters, and then passes the parameters to the motor drive board, PLC board, and DSP board; the main control bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com