Small-sample optimal quality control method based on process capability

A quality control method and small sample technology, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of large deviation of results, ignoring the use value of small samples, increasing false alarms or false detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention relates to a small sample optimal quality control method based on process capability, comprising the following steps:

[0027] (1) Determine the objective function: Among them, Z is the optimization constraint target value, R is the sample range, T is the standard tolerance set in advance, n is the number of sample groups, is the average range;

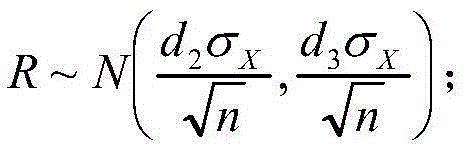

[0028] (2) Determining the constraints: For products produced in the same process, their ranges obey the normal distribution R ~ N ( d 2 σ X n , d 3 σ X n ) ;

[0029] Assuming that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com