Comb capacitive micro accelerometer

An accelerometer, comb capacitance technology, applied in the direction of measurement of acceleration, speed/acceleration/impact measurement, measurement device, etc., can solve the problems of small detection capacitance area, low measurement accuracy, large detection capacitance area, etc. The effect of increasing, high dimensional control accuracy, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0016] like figure 1 A comb-tooth capacitive micro-accelerometer shown is composed of a structural layer 1, an insulating layer 2, a substrate layer 3 and a base layer 4, and functional units are arranged on the structural layer 1 and the substrate layer 3, and the structural layer 1 and the substrate layer 4 The anchor point 5 is connected, the structural layer 1 is connected to the substrate layer 3 through the insulating layer 2 , and metal lead electrodes 6 are arranged on the substrate layer 4 and the substrate layer 3 . The material of the insulating layer 2 includes silicon dioxide.

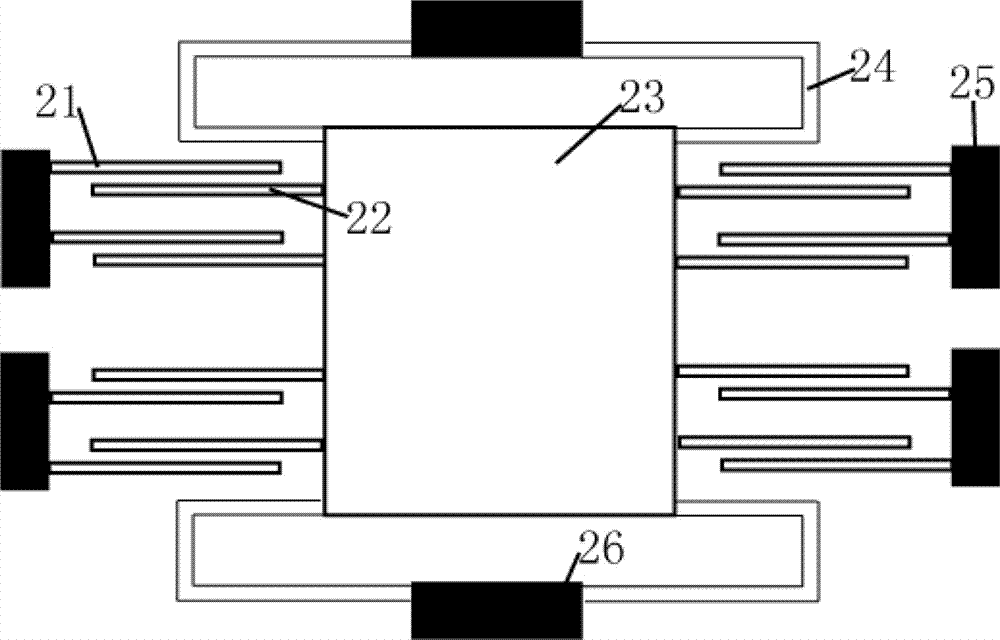

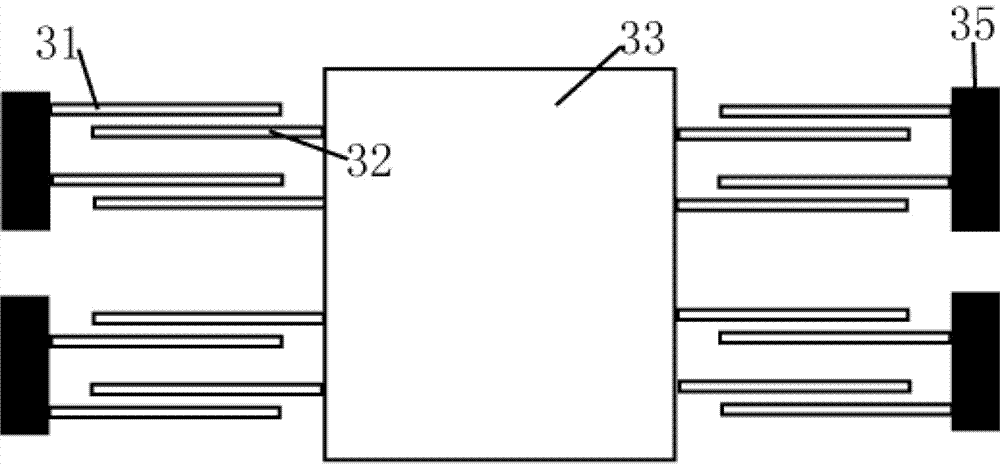

[0017] In order to realize sensing functions such as figure 2 As shown, a fixed electrode 21, a movable electrode 22, a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com