Laser scanning type bulk material flow detection and distribution error elimination method

A technology of laser scanning and error elimination, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., to achieve the effect of high degree of automation, simple structure, and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

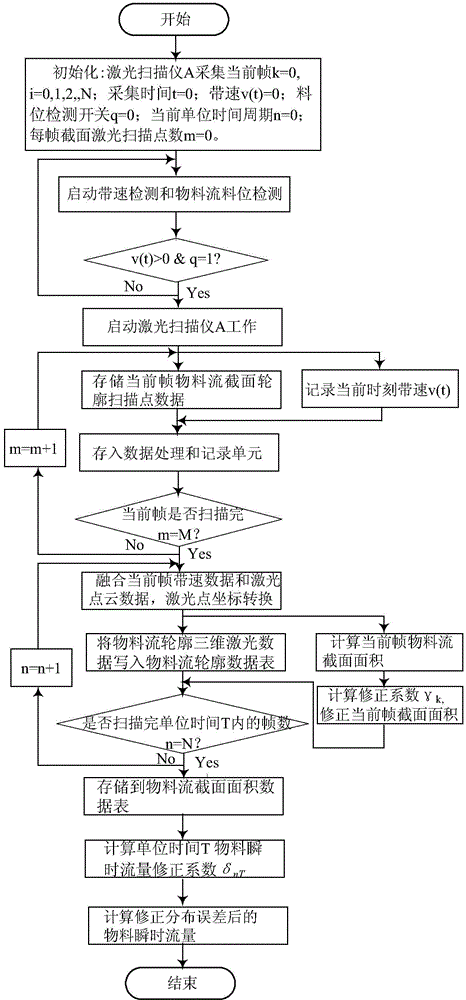

[0036] Below in conjunction with embodiment the present invention is described in further detail.

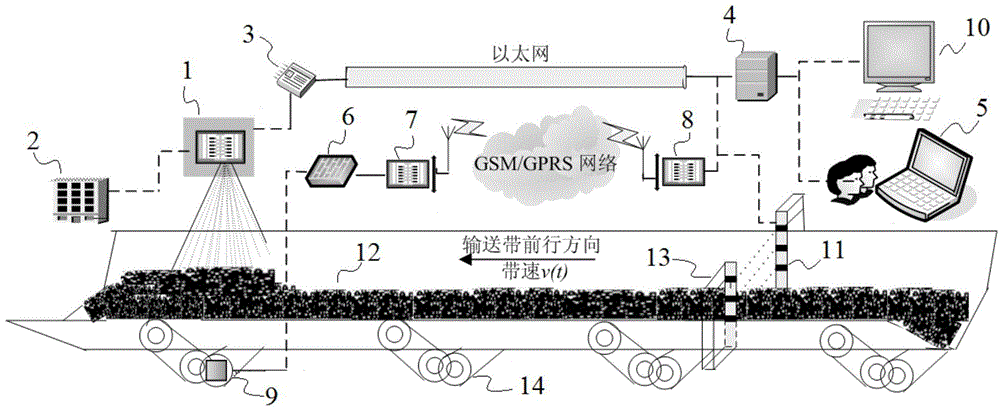

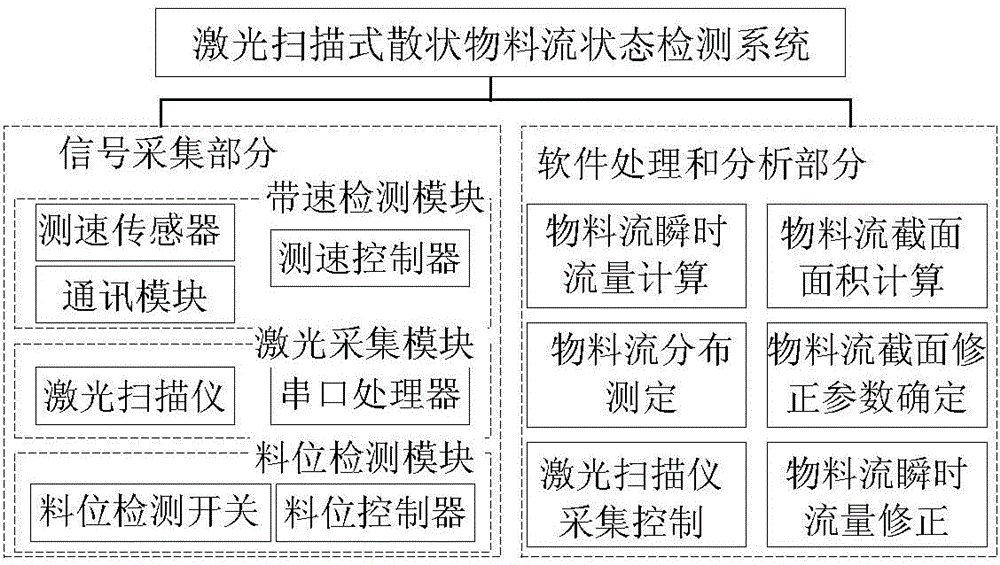

[0037] A laser scanning type bulk material flow detection and distribution error elimination system, the system includes a host computer, the host computer includes a material flow section profile detection module, a material level detection module, a belt speed detection module and a material distribution state measurement module.

[0038] The material flow cross-sectional profile detection module is provided by the material level detection module to collect the start signal, and the two-dimensional laser scanner is used to detect in real time the cross-sectional profile of the material flow through the laser scanning sector during the forward process of the conveyor belt, realizing the three-dimensional material flow profile of the belt conveyor Real-time acquisition of laser point cloud data.

[0039] The material level detection module is installed at a certain position away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com