Semi-W flame combustion subcritical steam pocket furnace

A flame combustion and subcritical technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of low-load stable combustion performance and other problems, and achieve the effect of reducing infrastructure investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

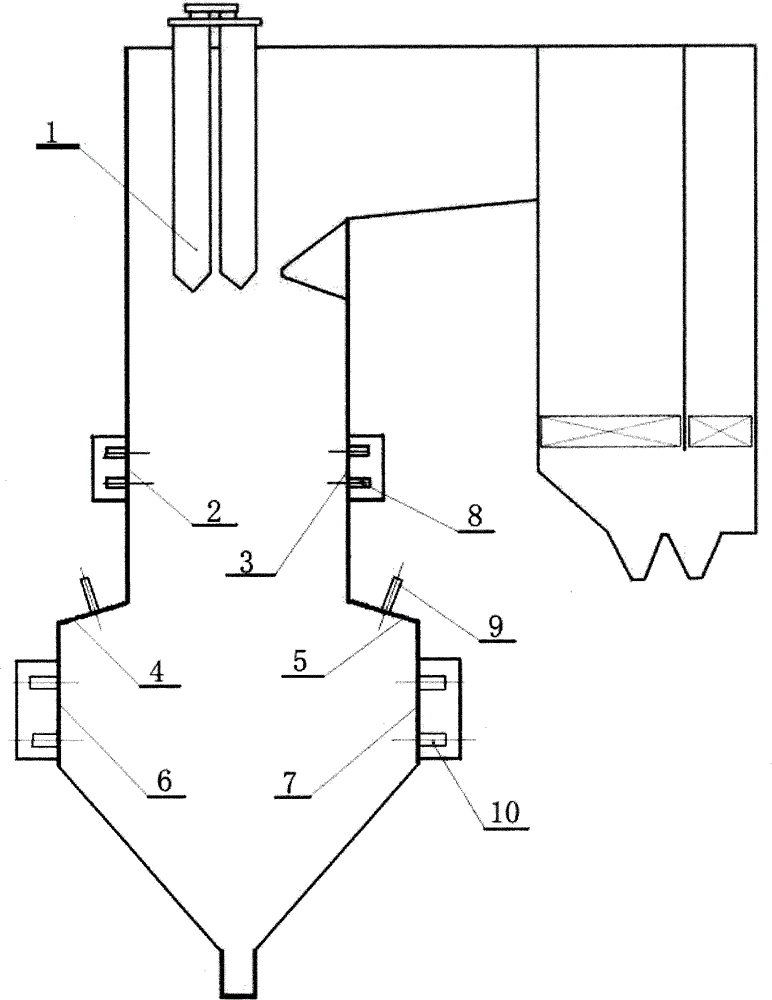

[0032] Combine now figure 1 Taking a 600MW grade primary reheating Π-type subcritical drum furnace with a design value of main steam temperature / reheating steam temperature of 540°C / 540°C as an example to illustrate the optimal way of realizing the invention.

[0033] The semi-"W" flame-combustion subcritical drum furnace of the present invention includes a lower furnace with a front arch and a rear arch; one row of weak swirl burners is respectively arranged on the front arch of the lower furnace and the rear arch of the lower furnace, and each row is evenly distributed 4 weak swirl burners; each row of weak swirl burners is connected with a double-inlet and double-outlet steel ball mill; 2 rows of double-air-regulating swirls are arranged on the lower parts of the front wall of the lower furnace and the rear wall of the lower furnace 4 double-adjustable air swirl burners are evenly distributed in each row; each row of double-adjustable air swirl burners is connected with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com