Equidistributed Angle Hydraulic Cylinder Motor with Undermine Emulsion Filter

A filter and hydraulic cylinder technology, applied in the field of mining hydraulic motors, can solve the problems of affecting normal production, long replacement time, high cost, etc., and achieve the effect of shortening cleaning time, good cleaning effect and fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

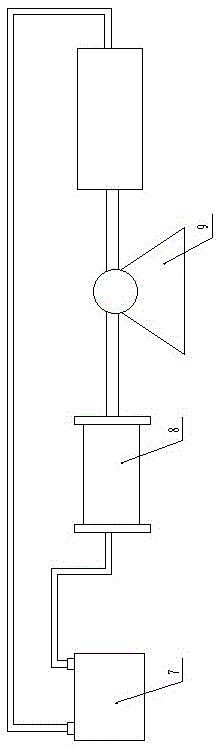

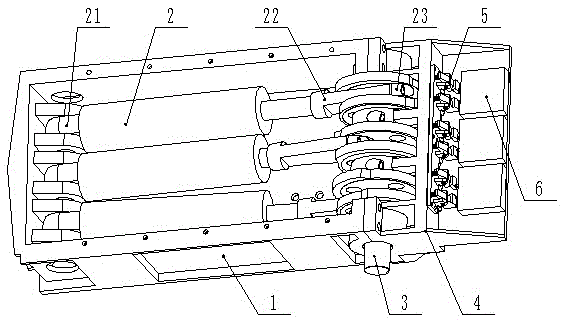

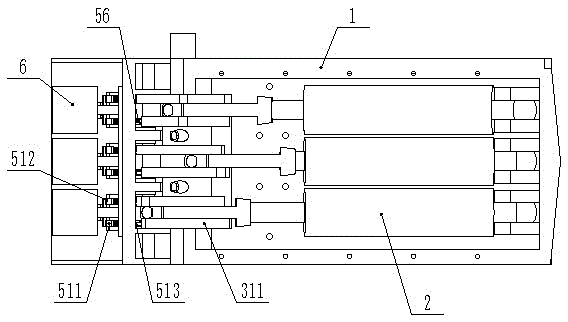

[0054] Such as figure 1 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 with Figure 16 As shown, the equidistributed angle hydraulic cylinder motor with the emulsion filter under the mine includes a fuel tank 7, a filter 8, an oil pump 9 and a hydraulic cylinder motor, the oil supply port of the fuel tank 7 and the oil inlet of the oil pump 9 They are connected through a filter 8, and the oil outlet of the oil pump 9 is connected with the oil return port of the oil tank 7 through a hydraulic cylinder motor.

[0055] Described filter 8 comprises outer cylinder 81, and one end of outer cylinder 81 is sealed by first end cap 82, and the other end is sealed by second end cap 83, and outer cylinder 81 is provided with mesh cylinder 84, and one end of mesh cylinder 84 is connected with the second end cap 83. One end cover 82 is connected through the first net tube end cover 85, and the other end is connected with the second end cover 83 through the second net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com