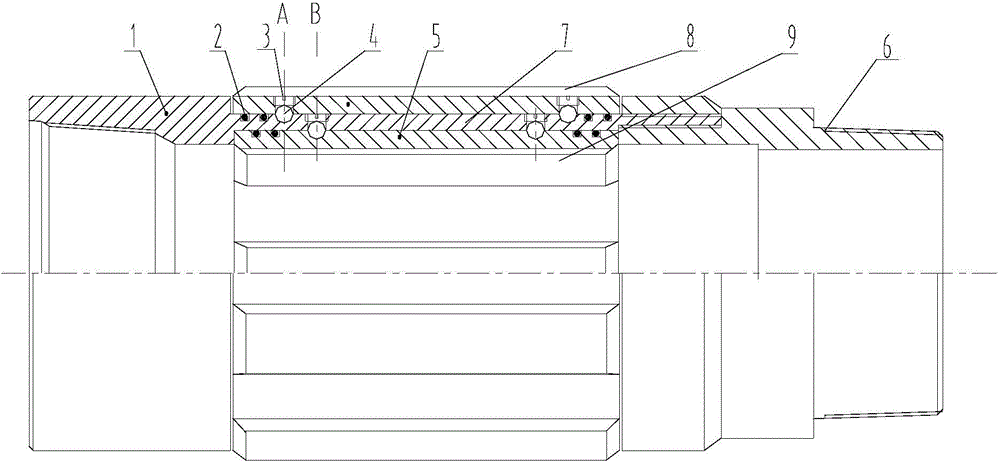

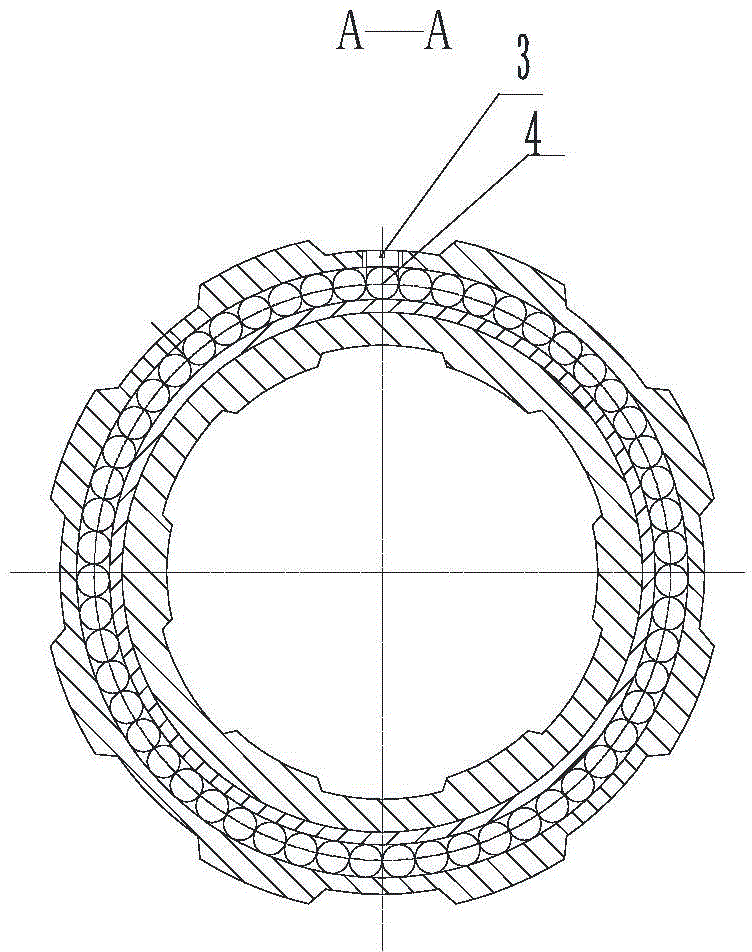

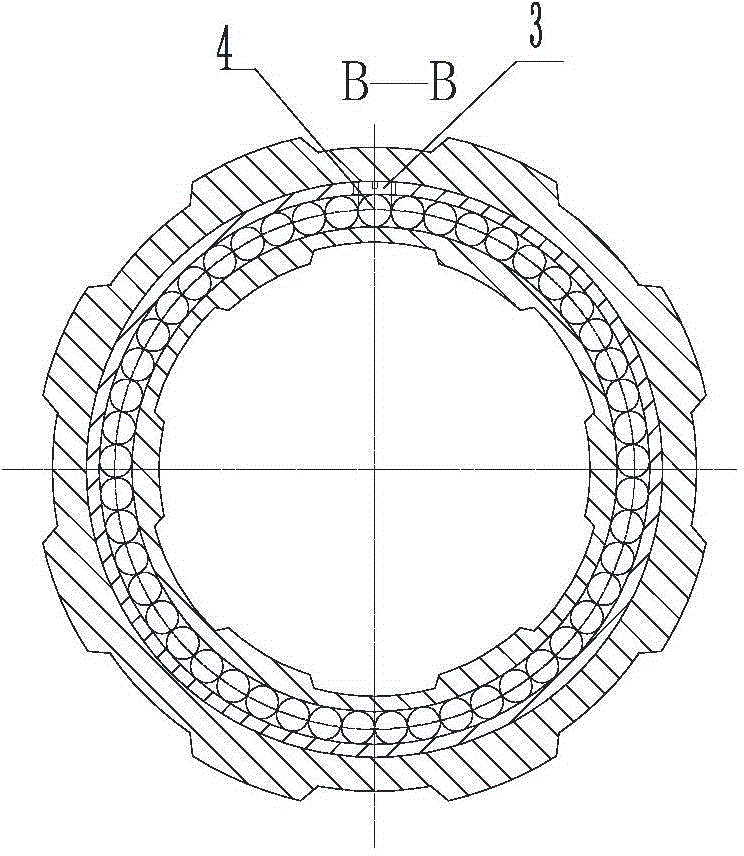

Shaft sleeve type inside-and-outside centralizer

A technology of centralizers and shaft sleeves, which is applied in the direction of casing, drilling equipment, earthwork drilling, etc., and can solve the problems of poor compatibility between casing milling strings and casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1: Well North 2-360-Deviation P35 in Daqing Oilfield, the inclination angle of this well is 0.5° at 200m and 9.2° at 300m, and the maximum build-up rate here is 18.4° / 100m, using one The casing milling tube structure is connected with an inner and outer centralizer, and the casing milling reaches 425m, and there is no jumping problem in the casing milling process.

example 2

[0018] Example 2: Well Nan 218-Xie 352 in Daqing Oilfield, the inclination angle of this well is 0.3° at 300m, and 8.9° at 450m, and the maximum inclination rate here is 16.9° / 100m. The sleeve milling pipe column structure connected with an inner and outer centralizer, the sleeve milling to 467m, no abnormal display during the sleeve milling process.

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com