Clean liquid fuel and preparation method thereof

A technology for cleaning liquids and fuels. It is applied in liquid carbon-containing fuels, fuels, and petroleum industries. It can solve the problems of non-conformity with economic and environmental protection, narrow application scope, and single incoming materials, and achieve environmentally friendly and clean raw materials. Environmentally friendly and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

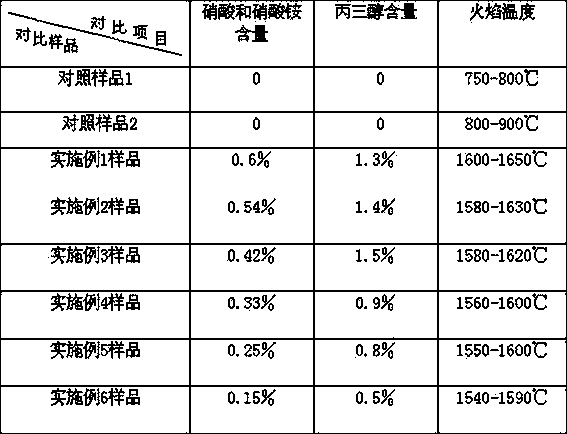

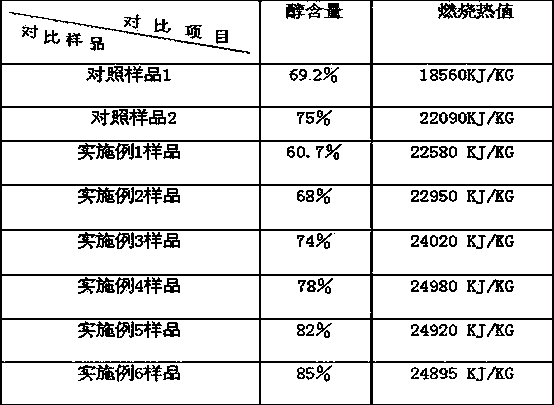

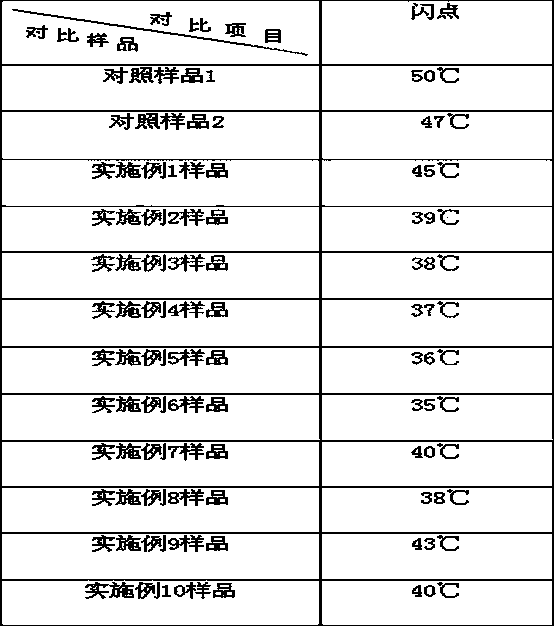

Embodiment 1

[0014] Weigh raw materials containing the following percentages by weight, methanol 50%, waste alcohol 10.7%, water 35%, toluene 1%, n-hexane 0.1%, ammonium nitrate 0.1%, glycerol 1.3%, nitric acid 0.5% and acetone 1.3% %;

Embodiment 2

[0016] Weigh raw materials containing the following percentages by weight, methanol 58%, waste alcohol 10%, water 28%, toluene 0.7%, n-hexane 0.06%, ammonium nitrate 0.09%, glycerol 1.4%, nitric acid 0.45% and acetone 1.3% %;

Embodiment 3

[0018] Weigh raw materials containing the following percentages by weight, methanol 60%, waste alcohol 14%, water 22%, toluene 0.5%, n-hexane 0.08%, ammonium nitrate 0.08%, glycerol 1.5%, nitric acid 0.34% and acetone 1.5% %;

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com