Yellow fluorescent powder used for white light LED and preparation method thereof

A yellow phosphor and phosphor technology, applied in the field of materials, can solve the problems of high price and high synthesis temperature of rare earth elements or red phosphors, and achieve the effects of promoting grain growth, increasing emission light intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned yellow fluorescent powder for white light LED comprises the following steps:

[0024] Step 1, according to chemical formula Y 2.94-x Ce 0.06 K 3x Al 5 o 12-1.5x f 3x The stoichiometric ratio weighs Y 2 o 3 or Y(NO 3 ) 3 、Al 2 o 3 or Al(NO 3 ) 3 , CeO 2 or Ce(NO 3 ) 4 , KF, fully mixed and put into an agate ball mill jar filled with ethanol for ball milling for 12h to 24h to obtain a slurry;

[0025] Step 2. Dry the slurry obtained in step 1 in a drying oven at 80°C to 90°C for 12h to 24h to obtain dry powder; then pre-fire the dry powder in an electric furnace at 1200°C to 1400°C for 3h to 12h, and cool naturally to At room temperature, the pre-burned reactant is obtained;

[0026] Step 3. Hand-grind the pre-burned reactant obtained in step 2 with an agate mortar for 10-30 minutes to make it fully pulverized, and then put it into a 95%-90% N 2 +5%~10%H 2 Heating to 1500°C-1600°C in an electric furnace with...

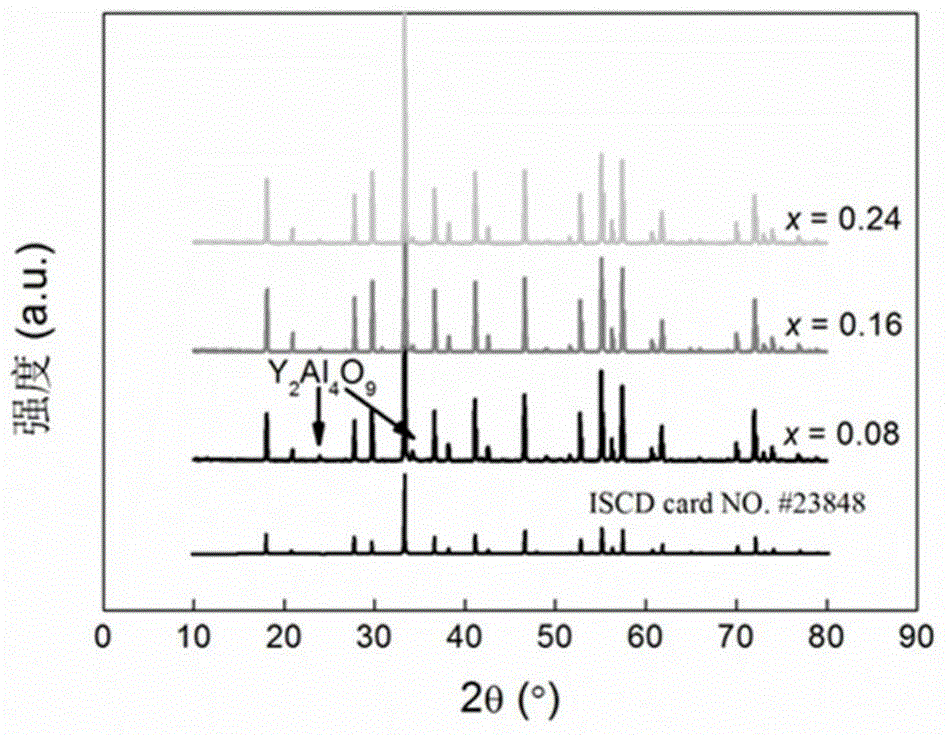

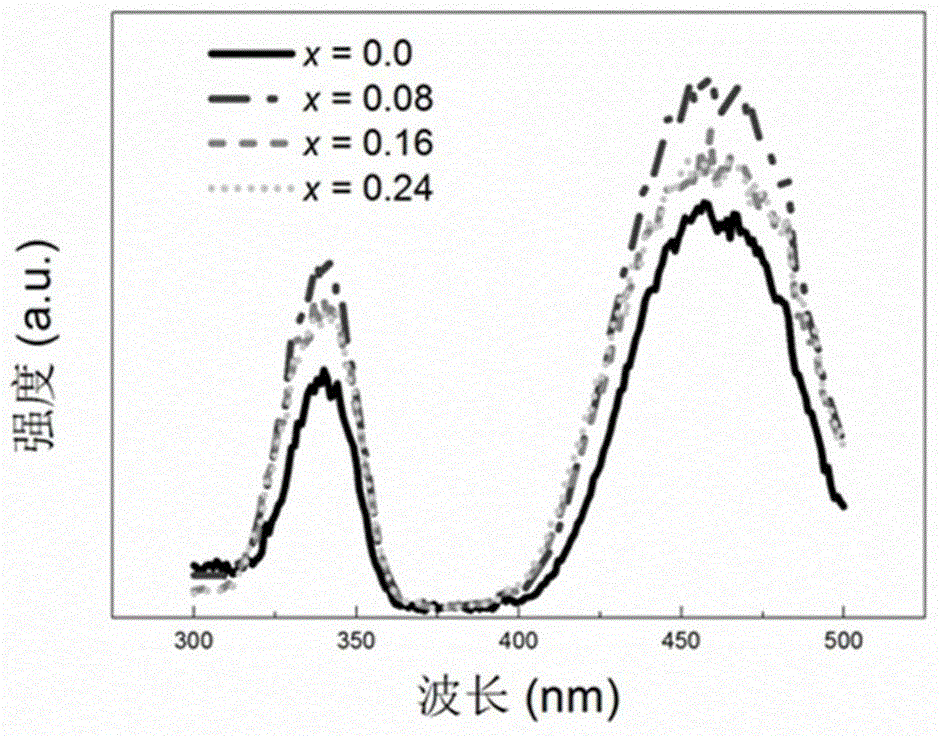

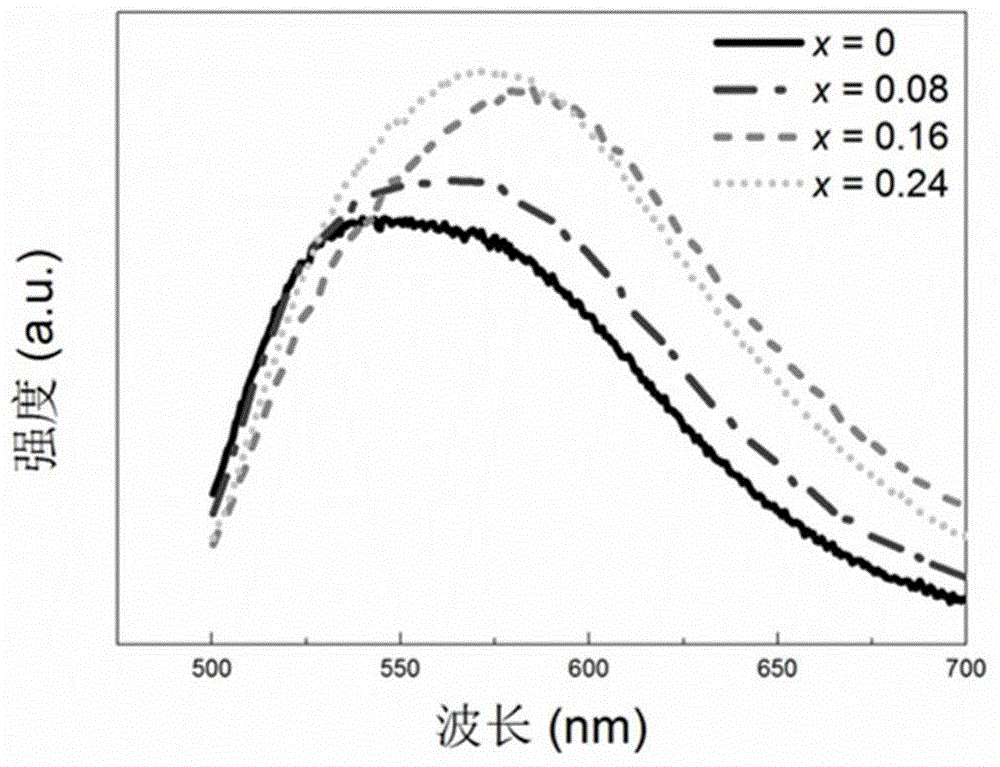

Embodiment 1

[0029] According to chemical formula Y 2.94-x Ce 0.06 K 3x Al 5 o 12-1.5x f 3x , x=0.08 stoichiometric ratio, weigh 32.29g of Y 2 o 3 , 25.50g of Al 2 o 3 , 1.03g of CeO 2After fully mixing with 1.39g of KF, put into an agate ball mill jar filled with ethanol and mill for 12 hours. Then the ball-milled slurry was dried in an oven at 90 °C for 12 h. The obtained dry powder was pre-fired in an electric furnace at 1300°C for 6 hours, and then cooled to room temperature naturally. Hand-grind the obtained pre-burned reactant with an agate mortar for 20 minutes to make it fully pulverized, and then put it into a 95% N 2 +5%H 2 Heat to 1500° C. in an electric furnace with a reducing atmosphere, keep warm for 6 hours, cool naturally to room temperature, and grind for 45 minutes to obtain yellow phosphor powder for white LEDs.

Embodiment 2

[0031] According to chemical formula Y 2.94-x Ce 0.06 K 3x Al 5 o 12-1.5x f 3x , x=0.16 stoichiometric ratio, weigh 31.39g of Y 2 o 3 , 25.50g of Al 2 o 3 , 1.03g of CeO 2 And the KF of 2.79g, after fully mixing, put into the agate ball mill jar that fills ethanol and ball mill for 12h. Then the ball-milled slurry was dried in an oven at 90 °C for 12 h. The obtained dry powder was pre-fired in an electric furnace at 1300°C for 6 hours, and then cooled to room temperature naturally. Hand-grind the obtained pre-burned reactant with an agate mortar for 20 minutes to make it fully pulverized, and then put it into a 95% N 2 +5%H 2 Heat to 1500° C. in an electric furnace with a reducing atmosphere, keep warm for 6 hours, cool naturally to room temperature, and grind for 45 minutes to obtain yellow phosphor powder for white LEDs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com