Method for continuously separating α-pinene and β-pinene from turpentine

A technology of turpentine and pinene, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of increasing raw material loss, prone to side reactions, and difficult control of the reaction process, etc., to prolong the collection time, increase the reflux ratio, and save energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

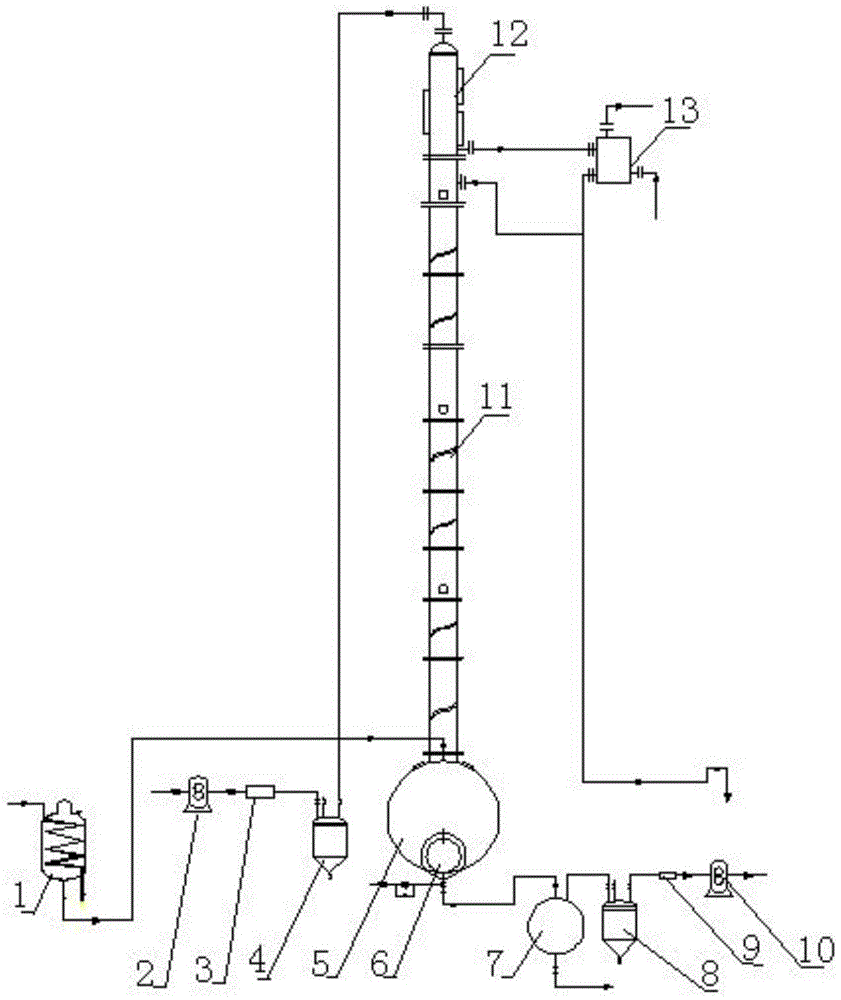

Method used

Image

Examples

Embodiment 1

[0026] Masson pine turpentine, the main components are: 80.5% α-pinene, 2.0% pinene, 8.2% β-pinene, 1.0% myrcene, 1.8% limonene, 3% longifolene, 0.5% β-caryophyllene. The air in the rectification tower is exhausted with a sliding valve vacuum pump, and the vacuum degree in the rectification tower reaches -0.09MPa. The raw material is sucked into the rectification tower tower through the negative pressure of the rectification tower tank and the raw material storage tank. Open the inlet valve of the column pipe heated by steam in the bottom of the rectification column to heat the raw materials in the bottom of the column, and at the same time open the water inlet valves of the condenser and cooler at the top of the tower. The temperature of the tower bottom is controlled at 100-110°C, the temperature of the top of the tower is controlled at 80-95°C, and the total reflux is 0.5-1h, then the product discharge valve is opened, the reflux ratio is controlled at 8:1-10:1, and the frac...

Embodiment 2

[0028] The main components of slash pine turpentine are: 59.2% α-pinene, 1.5% pinene, 28.2% β-pinene, 1.1% myrcene, and 8.5% limonene. The air in the rectification tower is exhausted with a sliding valve vacuum pump, and the vacuum degree in the rectification tower reaches -0.09MPa. The raw material is sucked into the rectification tower tower through the negative pressure of the rectification tower tank and the raw material storage tank. Open the inlet valve of the column pipe heated by steam in the bottom of the rectification column to heat the raw materials in the bottom of the column, and at the same time open the water inlet valves of the condenser and cooler at the top of the tower. The temperature of the tower bottom is controlled at 100-110°C, the temperature of the top of the tower is controlled at 80-95°C, and the total reflux is 0.5-1h, then the product discharge valve is opened, the reflux ratio is controlled at 8:1-10:1, and the fractionated product is Perform spe...

Embodiment 3

[0030]Simao pine turpentine oil (β-pinene type), the main components are: α-pinene 49.5%, pinene 1.2%, β-pinene 39.4%, 3-carene 3.7%, limonene 0.86%, longifolene 3 %, β-caryophyllene 0.5%. The air in the rectification tower is exhausted with a sliding valve vacuum pump, and the vacuum degree in the rectification tower reaches -0.09MPa. The raw material is sucked into the rectification tower tower through the negative pressure of the rectification tower tank and the raw material storage tank. Open the inlet valve of the column pipe heated by steam in the bottom of the rectification column to heat the raw materials in the bottom of the column, and at the same time open the water inlet valves of the condenser and cooler at the top of the tower. The temperature of the tower bottom is controlled at 100-110°C, the temperature of the top of the tower is controlled at 80-95°C, and the total reflux is 0.5-1h, then the product discharge valve is opened, the reflux ratio is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com