Spherical SiO2 material with radial mesoporous structure and preparation method of spherical SiO2 material

A technology of spherical silica and pore structure, applied in the direction of silica, silicon oxide, etc., to achieve the effect of cheap raw materials, good repeatability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

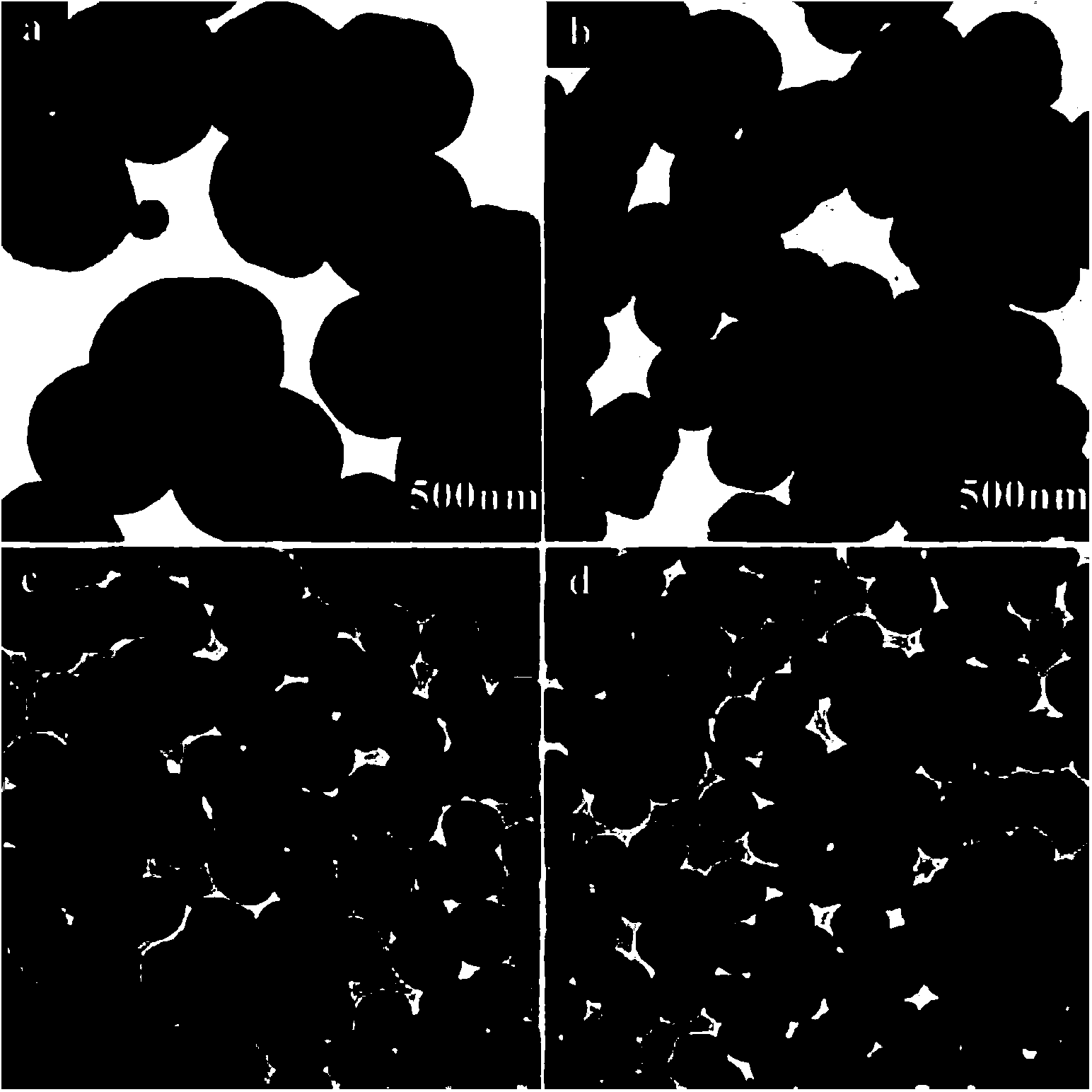

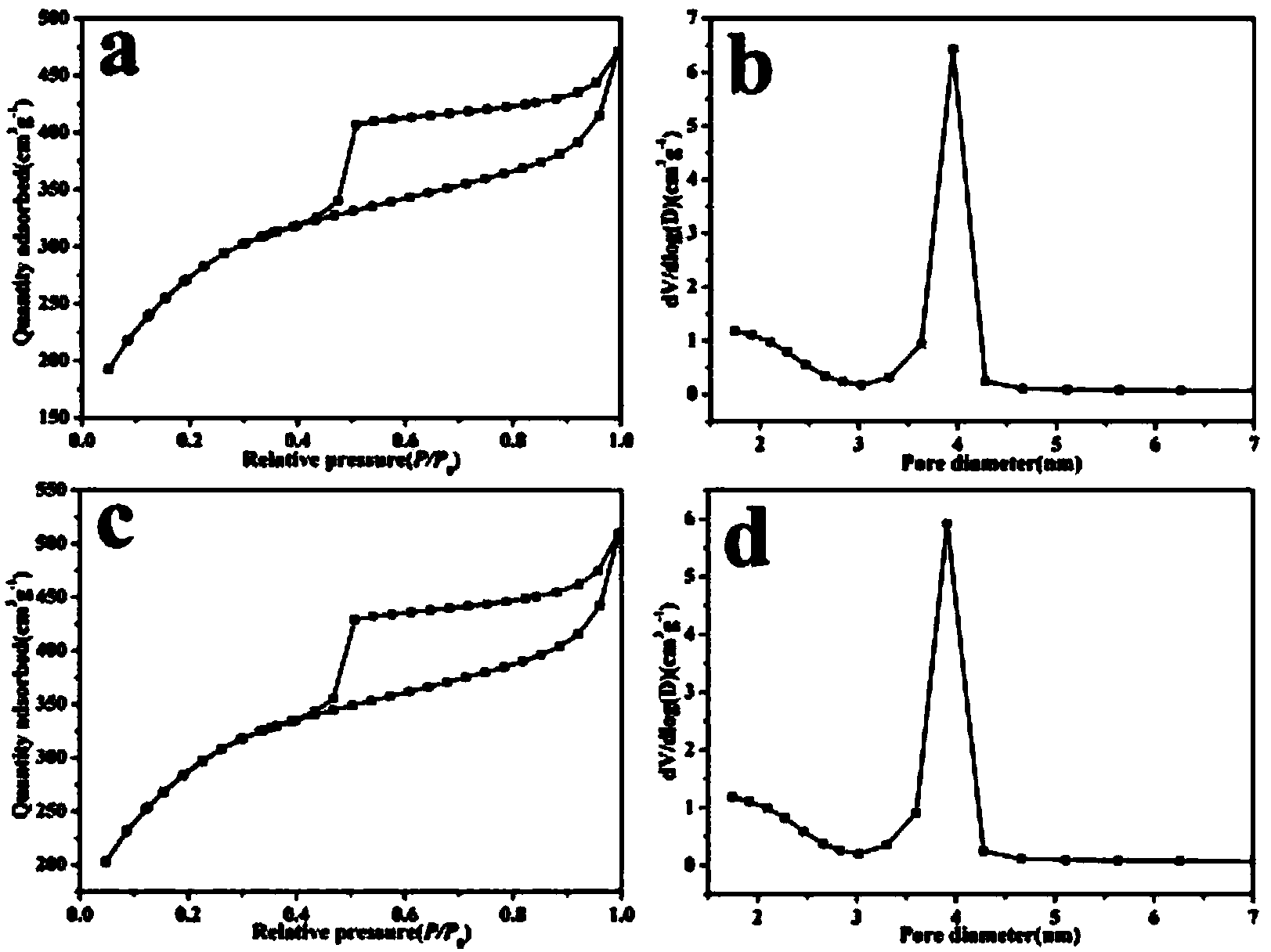

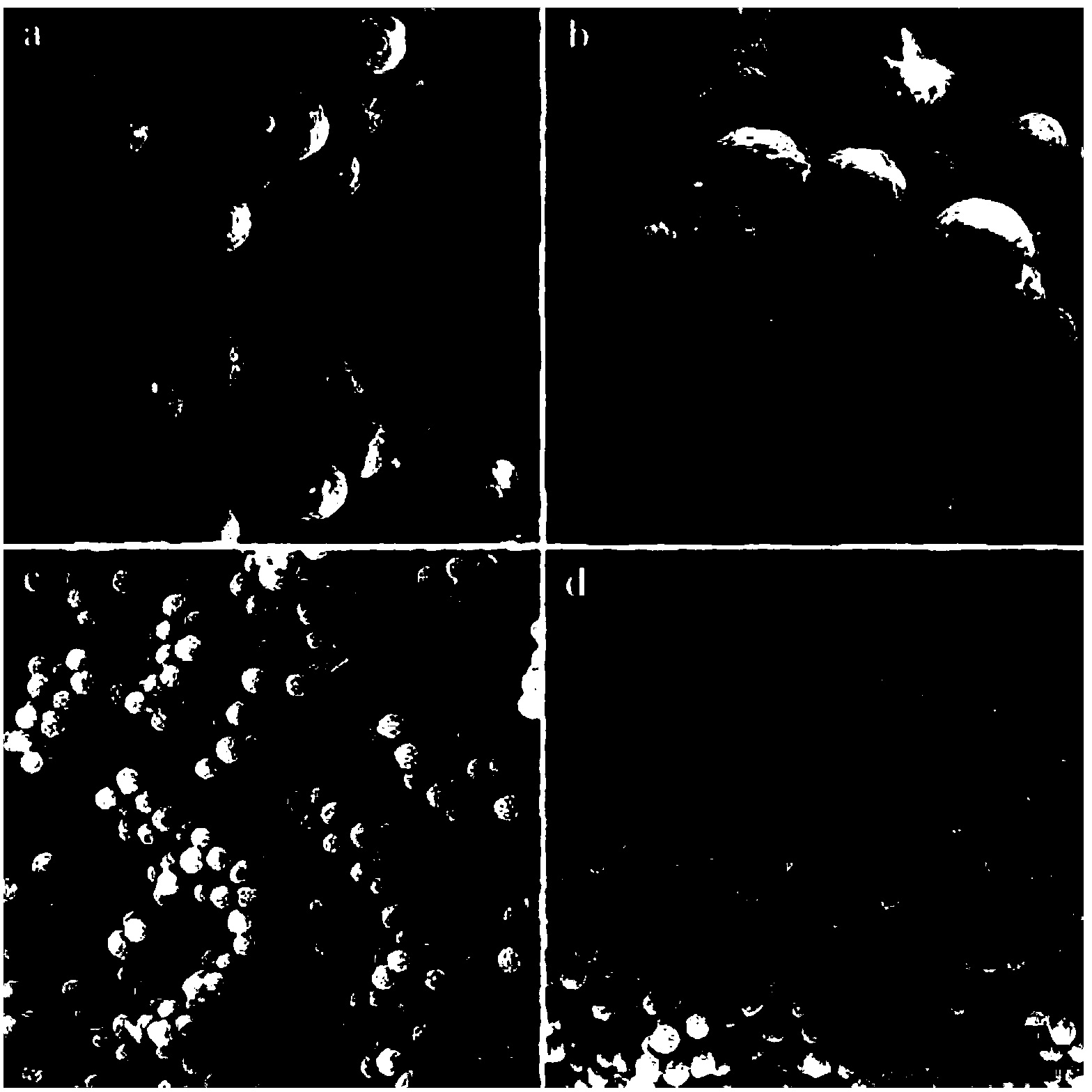

[0032](1) At room temperature, 0.5g of TEOS was dispersed in 2mL of cyclohexane solution; (2) At room temperature, 0.08g of CTAB was added to 25mL of distilled water and 15mL of ethanol mixed solution, stirring continuously until a transparent solution was formed; Under the condition of constant stirring, the solution obtained in step (1) is quickly added to the transparent solution obtained in step (2), and stirred for 2 hours to form a mixed solution; (4) add 0.5 mL of the mixed solution obtained in step (3) Ammonia, continue to stir and react at 35°C for 4h; (5) centrifuge the precipitate in step (4), wash it with distilled water for 3 times, and dry it at 60°C for 24h in a blast drying oven to obtain the product; (6) The product obtained in step (5) is placed in a box-type calciner and calcined at 550 ° C for 6 hours to obtain SiO 2 powder. TEM of the product as figure 1 As shown in a, mesoporous SiO 2 The average particle size of the sphere is 650nm, and the mesopore d...

Embodiment 2

[0034] (1) Disperse 0.5g of TEOS in 3mL of cyclohexane solution; (2) At room temperature, add 0.08g of CTAB into 25mL of distilled water and 15mL of ethanol mixed solution, stirring continuously until a transparent solution is formed; (3) in Under the condition of constant stirring, the solution obtained in step (1) is quickly added to the transparent solution obtained in step (2), and stirred for 2 hours to form a mixed solution; (4) add 0.5 mL of the mixed solution obtained in step (3) Ammonia, continue to stir and react at 35°C for 4h; (5) centrifuge the precipitate in step (4), wash it twice with distilled water, and dry it at 60°C for 24h in a blast drying oven to obtain the product; (6) The product obtained in step (5) is placed in a box-type calciner and calcined at 550 ° C for 6 hours to obtain SiO 2 powder. TEM of the product as figure 1 As shown in b, mesoporous SiO 2 The average particle size of the spheres is 450nm, the mesopore diameter is 3.95nm, and radial ra...

Embodiment 3

[0036] (1) At room temperature, 0.5g of TEOS was dispersed in 4mL of cyclohexane solution; (2) 0.08g of CTAB was added to 25mL of distilled water and 15mL of ethanol mixed solution, stirring continuously until a transparent solution was formed; (3) in Under the condition of constant stirring, the solution obtained in step (1) is quickly added to the transparent solution obtained in step (2), and stirred for 2 hours to form a mixed solution; (4) add 0.5 mL of the mixed solution obtained in step (3) Ammonia, continue to stir and react at 35°C for 4h; (5) centrifuge the precipitate in step (4), wash it with distilled water for 3 times, and dry it at 60°C for 24h in a blast drying oven to obtain the product; ) The product obtained is placed in a box-type calciner and calcined at 550°C for 6h to obtain SiO 2 powder. Product Mesoporous SiO 2 The average particle size of the ball is 400nm, the mesopore diameter is 3.91nm, and the specific surface area is 1046m 2 / g. Product N 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com