Injection mould with specially-shaped conformal cooling water channel and manufacturing method thereof

A conformal cooling, injection mold technology, applied in the directions of additive manufacturing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems such as the inability to realize the processing of the inner hole of the cooling water channel and the inability to adapt to the molding volume, and achieve the simple and feasible process of burying the pipe. , the effect of increasing the disturbance and enhancing the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

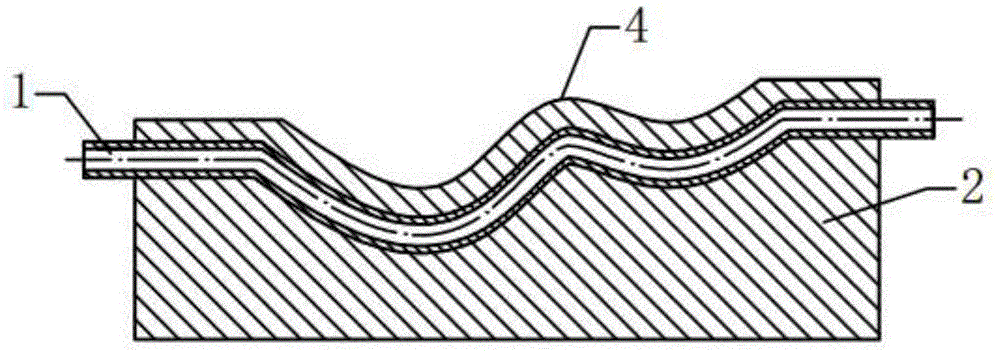

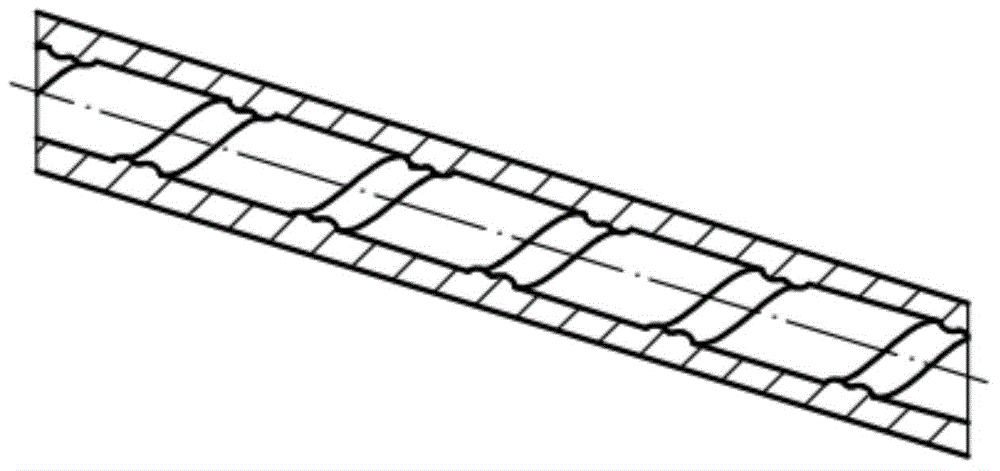

[0027] like Figure 2 to Figure 6 As shown, an injection mold with a special-shaped conformal cooling water channel includes a mold body 2 provided with a cavity 4, and the mold body 2 is embedded with a conformal cooling water channel 1 that is consistent with the contour of the cavity 4, The distance between the conformal cooling water channel 1 and the surface of the cavity 4 is 1 to 2 times the diameter of the cooling water channel, which is 1 time in this embodiment; Bellows, Scaled Tubular or Grooved Tubular. The conformal cooling water channel 1 in this embodiment adopts a special-shaped water channel, thereby increasing the disturbance of the cooling medium in the cooling water channel, easily forming turbulent flow, enhancing the heat transfer effect, improving the heat dissipation performance of the mold, and preventing the product from warping due to uneven cooling. Quality issues.

Embodiment 2

[0029] A manufacturing method of an injection mold with a special-shaped conformal cooling water channel, comprising the steps of:

[0030] In step 1, the metal powder material is manufactured into a conformal cooling water channel 1 by using the selective laser melting molding technology. Figure 3 to Figure 6 );

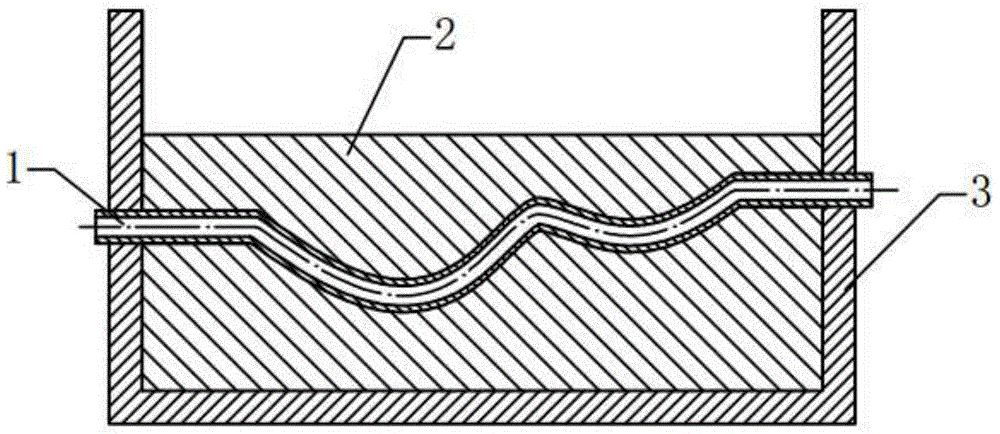

[0031] Step 2: Fix the conformal cooling water channel 1 in the casting cavity 3 for casting the mold body 2 (see figure 1 );

[0032] In step 3, the molten aluminum alloy is cast to form the mold body 2 (see figure 1 ), low carbon steel or zinc alloy can also be used as required;

[0033] In step 4, a cavity 4 is machined on the mold body 2 by machining (see figure 2 ).

[0034] In the present invention, the cross-sectional shape of the conformal cooling water channel 1 can adopt the shape of equal cross-section, and can also adopt the shape of special-shaped and deformed cross-section. Figure 2 to Figure 6 Structure.

[0035] The above-mentioned steps of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com