Nanometer silicon dioxide thin film base polished section and preparation method thereof

A technology of nano-silica and silanol, which is applied in the direction of grinding/polishing equipment, manufacturing tools, epoxy resin coatings, etc., and can solve the problem of inability to provide high cutting force, uneven cutting force, and poor cutting effect, etc. problem, to achieve the effect of promoting bonding fastness, good cutting effect and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of nano-silica sol: adding 10ml mass concentration to 500ml alcohol-soluble silica (Nissan Chemical, IP-ST) is 10% hydrochloric acid, 20ml surface modifier KH-570, 6g water, slowly stirring, Heating to 70°C, reacting for 8 hours and then evaporating and concentrating to about 200ml to obtain nano-silica sol. The particle size in the nano-silica sol was detected to be about 90nm.

[0037] (2) Pretreatment of the base material: Coating 909 (Nanya epoxy resin) with 1% of the curing agent N3390 (Bayer, Germany) on the PET tape base to form a pre-coating layer, cured at 60°C for 24 hours for later use ;

[0038] (3) After mixing the nano-silica sol obtained in step (1), the second soluble resin and the soluble curing agent, configure the abrasive coating solution according to the consumption in Table 1, wherein the weight content of silicon dioxide after drying is 82%;

[0039] The composition of the abrasive coating liquid of table 1 embodiment 1

[0040] ...

Embodiment 2

[0047]The operation of this embodiment is the same as that of Example 1, except that the composition of the abrasive coating liquid is different, the content of silicon dioxide is 50%, and the composition is shown in Table 3.

[0048] The composition of the abrasive coating liquid of table 3 embodiment 2

[0049] components

Weight (g)

Non-volatile components (%)

Weight after drying (g)

Nano silica sol

71.42

28

20.00

EXP0334 (Shandong Shengquan)

41.33

30

12.40

909 (South Asia Epoxy Resin)

12.00

50

6.00

N3390 (Bayer, Germany)

2.67

60

1.60

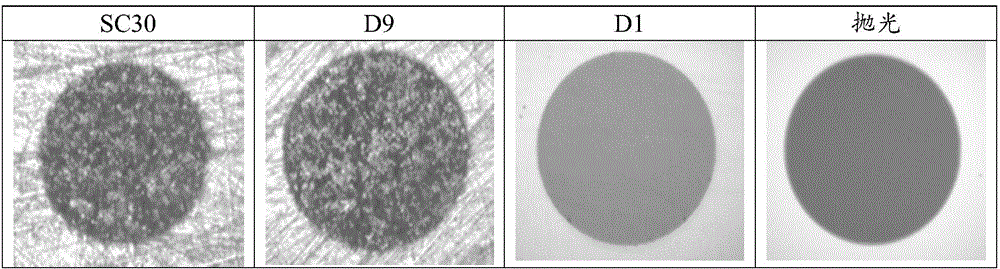

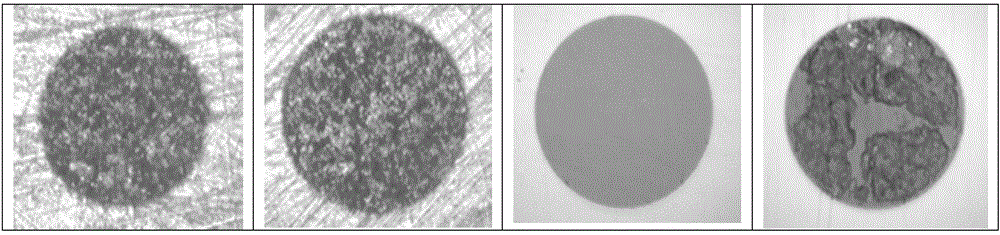

[0050] The obtained nano-silica film-based polishing sheet grinds the end face of the optical fiber according to the same grinding conditions as in Example 1, evaluates its grinding effect, and the picture of the obtained grinding end face enlarged by 200 times is as follows figure 2 shown.

[0051] Depend on figure 2 It can be seen tha...

Embodiment 3

[0053] The operation of this embodiment is the same as that of Example 1, except that the composition of the abrasive coating liquid is different, the silicon dioxide content is 90%, and the composition is shown in Table 4.

[0054] The composition of the abrasive coating liquid of table 4 embodiment 3

[0055] components

Weight (g)

Non-volatile components (%)

Weight after drying (g)

Nano silica sol

71.42

28

20.00

EXP0334 (Shandong Shengquan)

4.59

30

1.38

[0056] 909 (South Asia Epoxy Resin)

1.33

50

0.67

N3390 (Bayer, Germany)

0.29

60

0.18

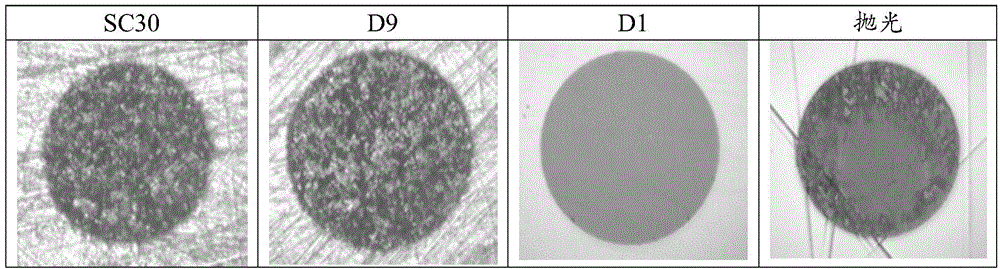

[0057] The obtained nano-silica film-based polishing sheet grinds the end face of the optical fiber according to the same grinding conditions as in Example 1, evaluates its grinding effect, and the picture of the obtained grinding end face enlarged by 200 times is as follows image 3 shown.

[0058] Depend on image 3 It can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com