Rotary quick uniform low-energy heating furnace structure for metal billets

A rotary, metal billet technology, which is applied in the heating field of aluminum alloy forging and extrusion forming billets, can solve the problems of low production efficiency of equipment, prolonging the heating and holding time of billets, and insufficient core temperature, etc., so as to reduce the cost of land use in the workshop , Reduce the oxidation loss of the billet, and the effect of uniform and stable heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

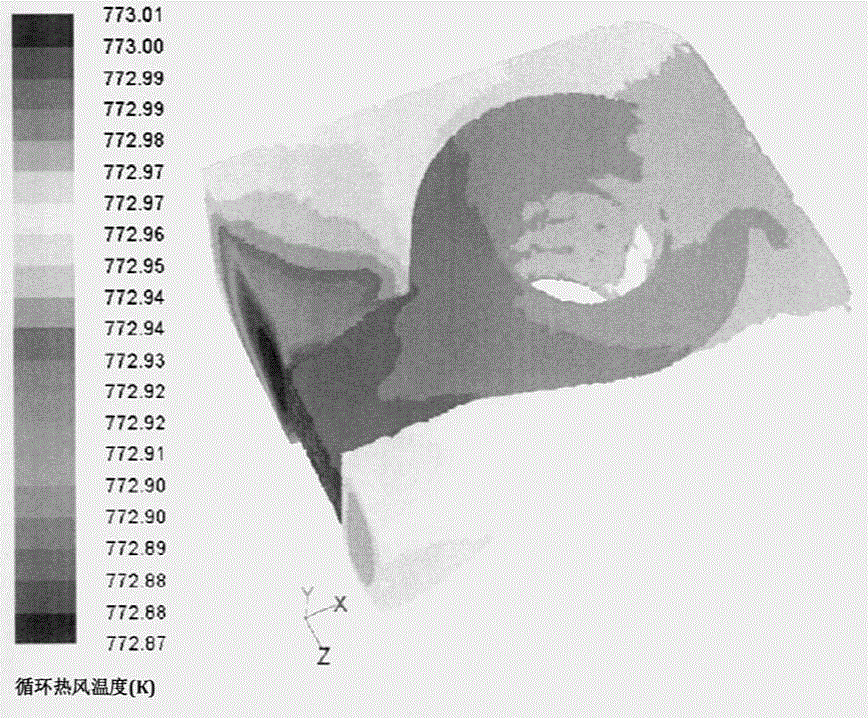

[0056]The present invention specifically implements a "rotary metal billet fast, uniform and low-energy consumption heating furnace structure" suitable for the field of metal forging and extrusion molding, especially the field of aluminum alloy forging and extrusion molding

[0057] The key technical problems to be solved by the specific implementation of the present invention are the uniform distribution of circulating hot air and high-speed flow in the furnace, the realization of rapid and uniform heating of billets, the utilization of hot air with high efficiency and low consumption, the control of wind blowing and suction from the furnace door, and the heating of billets with low energy consumption.

[0058] The detailed features of the specific implementation of the present invention are as follows:

[0059] The layered hot air guide plate (1a, 1b, 1c, 1d, 1e) structure with the optimal configuration of hot air inlet is set, and the hot air can be effectively distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com