Method for recovering calcium salt by treating high Cl high CO2 burning flue gas and waste burning fly ash water washing lotion

A technology of waste incineration fly ash and incineration flue gas, applied in separation methods, chemical instruments and methods, water/sewage multi-stage treatment, etc., to achieve the effects of saving water, reducing environmental pollution, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 (the water-cement ratio is 3:1, and the flue gas is fed to pH=8.5)

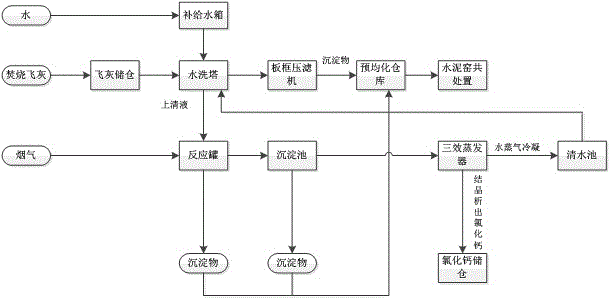

[0019] The implementation process is shown in the attached figure. The scale of the experiment is to process 1 ton of fly ash per day, and the water-cement ratio is 3:1. The concentration of Pb in the wastewater generated during pretreatment is 36.72mg / L, the concentration of Cr is 1.37mg / L, the concentration of Cd is 0.35mg / L, the concentration of Cu is 0.82mg / L, the concentration of Zn is 2.04mg / L, and the concentration of Ni 0.57mg / L, both exceeding GB18918-2002 "Pollutant Discharge Standards for Urban Sewage Treatment Plants". The concentration of hydrogen chloride in the flue gas of medical waste incineration is 350 mg / L, which is much higher than GB18484-2001 "Pollution Control Standards for Hazardous Waste Incineration". The method of the present invention is used to fully react the two, and after the pH of the washing solution is reduced to 8.5, the concentration of hydrogen chloride...

Embodiment 2

[0021] Example 2 (the water-cement ratio is 3:1, and the flue gas is fed to pH=7.5)

[0022] The implementation process is shown in the attached figure. The scale of the experiment is to process 1 ton of fly ash per day, and the water-cement ratio is 3:1. The concentration of Pb in the wastewater generated during pretreatment is 36.72mg / L, the concentration of Cr is 1.37mg / L, the concentration of Cd is 0.35mg / L, the concentration of Cu is 0.82mg / L, the concentration of Zn is 2.04mg / L, and the concentration of Ni 0.57mg / L, both exceeding GB18918-2002 "Pollutant Discharge Standards for Urban Sewage Treatment Plants". The concentration of hydrogen chloride in the flue gas of medical waste incineration is 350 mg / L, which is much higher than GB18484-2001 "Pollution Control Standards for Hazardous Waste Incineration". The method of the present invention is used to fully react the two, and after the pH of the washing liquid is reduced to 7.5, the concentration of hydrogen chloride i...

Embodiment 3

[0024] Example 3 (the water-cement ratio is 8:1, and the flue gas is fed to pH=8.5)

[0025] The implementation process is shown in the attached figure. The scale of the experiment is to process 1t of fly ash per day, and the water-cement ratio is 8:1. The concentration of Pb in the wastewater generated during pretreatment is 26.60mg / L, the concentration of Cr is 1.03mg / L, the concentration of Cd is 0.31mg / L, the concentration of Cu is 0.59mg / L, the concentration of Zn is 1.07mg / L, and the concentration of Ni 0.51mg / L, both exceeding GB18918-2002 "Pollutant Discharge Standards for Urban Sewage Treatment Plants". The concentration of hydrogen chloride in the flue gas of medical waste incineration is 350 mg / L, which is much higher than GB18484-2001 "Pollution Control Standards for Hazardous Waste Incineration". Using the method of the present invention to make the two fully react, after the pH of the washing liquid is reduced to 8.5, the concentration of hydrogen chloride is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com