Preparation method for slow-release type imidacloprid granules

A technology for imidacloprid and granules, which is applied in the field of preparation of slow-release imidacloprid granules, can solve the problems of low utilization rate of pesticides, loss, surface or groundwater pollution, etc., and achieves the effects of simple processing, reduced pollution and light specific gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

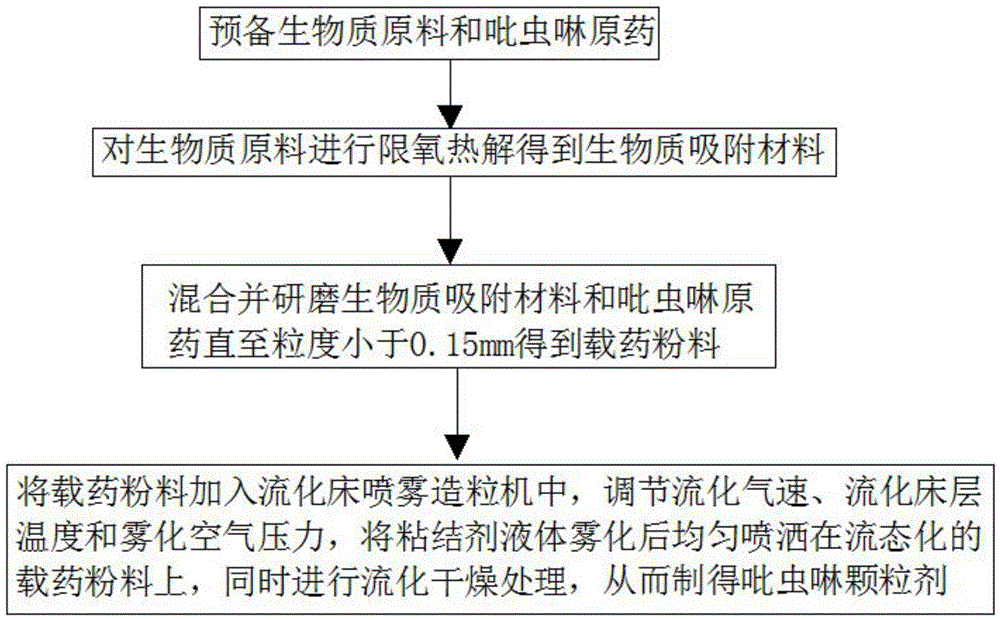

[0024] figure 1 It is a schematic flow chart of the preparation method of the sustained-release imidacloprid granules provided in Example 1 of the present invention; as shown in the figure, the preparation method of the sustained-release imidacloprid granules provided in Example 1 of the present invention includes:

[0025] First, prepare biomass raw materials and imidacloprid raw materials, the biomass raw materials are straw, wood chips, leaves, and other biomass waste in agricultural or forestry production;

[0026] Then, the biomass raw material is subjected to oxygen-limited pyrolysis (ie, isolating oxygen for pyrolysis) at a temperature of 200°C to 500°C, to obtain a biomass adsorbent, which has a pore structure and hydrophobicity. Carbon compounds with high adsorption capacity for imidacloprid;

[0027] Then mix the biomass adsorption material and imidacloprid technical uniformly according to the mass ratio of 2-10:1, such as 2:1, 3:1, 4:1, 5:1, 6:1, 7:1, 8 : 1, 9:1, 10:1, et...

Embodiment 2

[0030] Weigh 300g of dried leaves, put them in several crucibles in batches, put the crucible lids on them, put them into the muffle furnace, heat up to 300°C, keep them warm for 3h, cool down and wait for the crucible to cool to room temperature, then take out the residual carbon in the crucible , Washed with water and adjusted to pH=6.5, dried and pulverized the solid after suction filtration to obtain 72 g of biomass adsorption material.

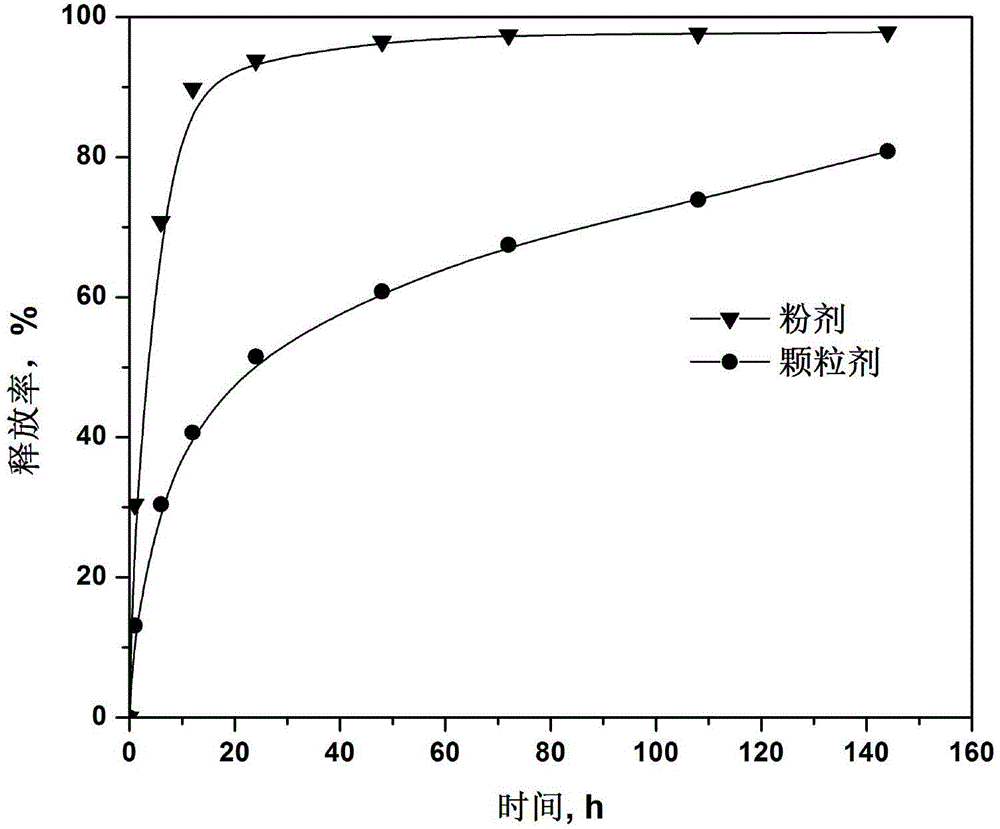

[0031] Grind and mix the above-mentioned biomass adsorbent and 15 g of imidacloprid original drug (purity 95%), grind and sieve (aperture 0.15 mm) to obtain drug-loaded powder. Then, add the drug-loaded powder to the fluidized bed spray granulator, use 0.5% (mass concentration) sodium alginate aqueous solution as the binder, adjust the fluidizing gas velocity to 1.5m / s, and the fluidized bed temperature to 60 , The atomizing air pressure is 0.3MPa, and the binder liquid is atomized and sprayed evenly on the fluidized drug-carrying powder. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com