Finned bipolar junction transistor and manufacturing method thereof

A bipolar junction and transistor technology, applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of PN junction position variation and small PN junction area of fin bipolar junction transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0053] This embodiment will describe in detail the method of fabricating a fin bipolar junction transistor.

[0054] Figure 4A to Figure 6B It is a structural schematic diagram of the method for preparing a fin bipolar junction transistor in this specific embodiment, which will be combined below Figure 4A to Figure 6B A first embodiment of the present invention will be described in detail.

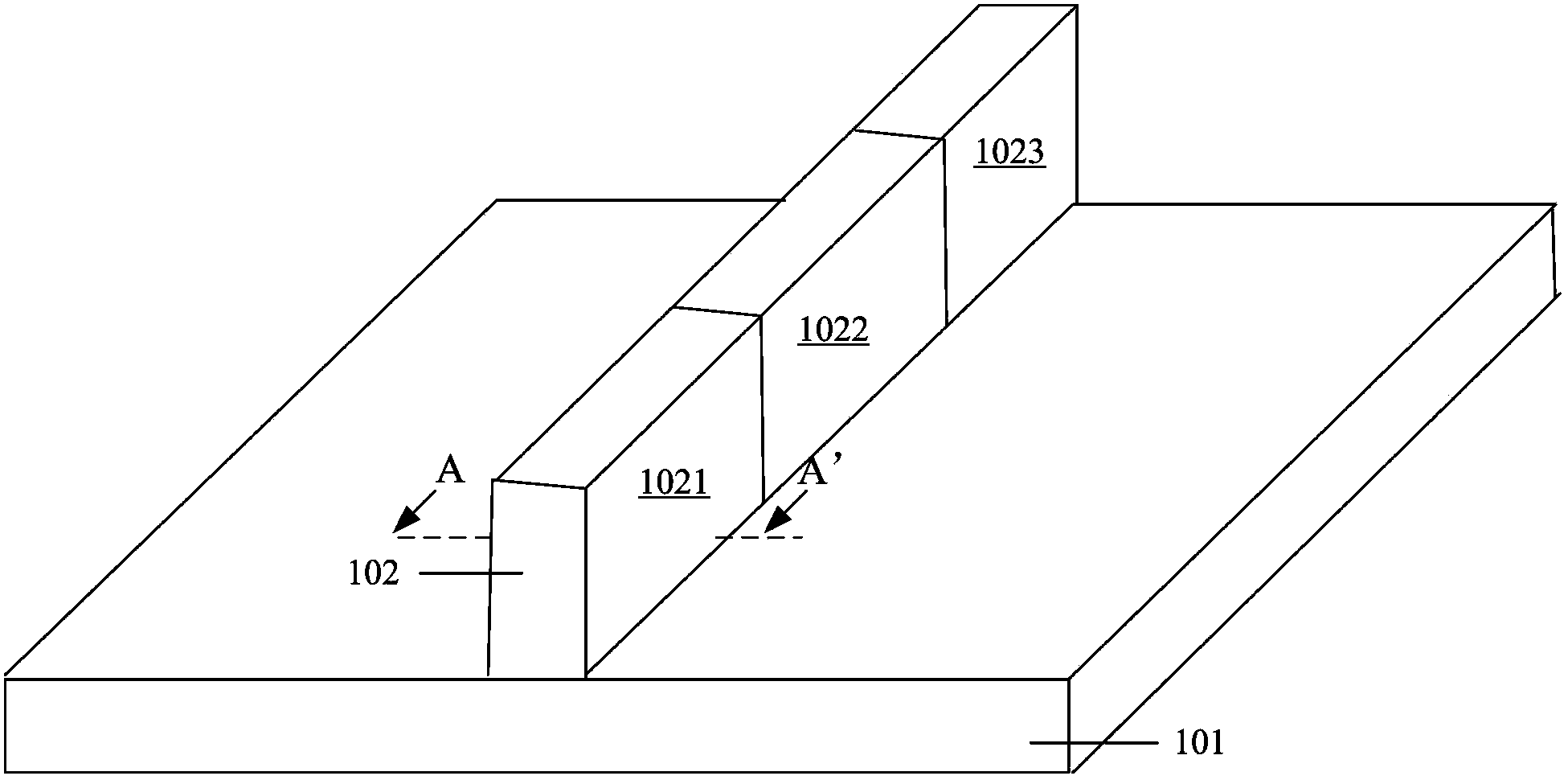

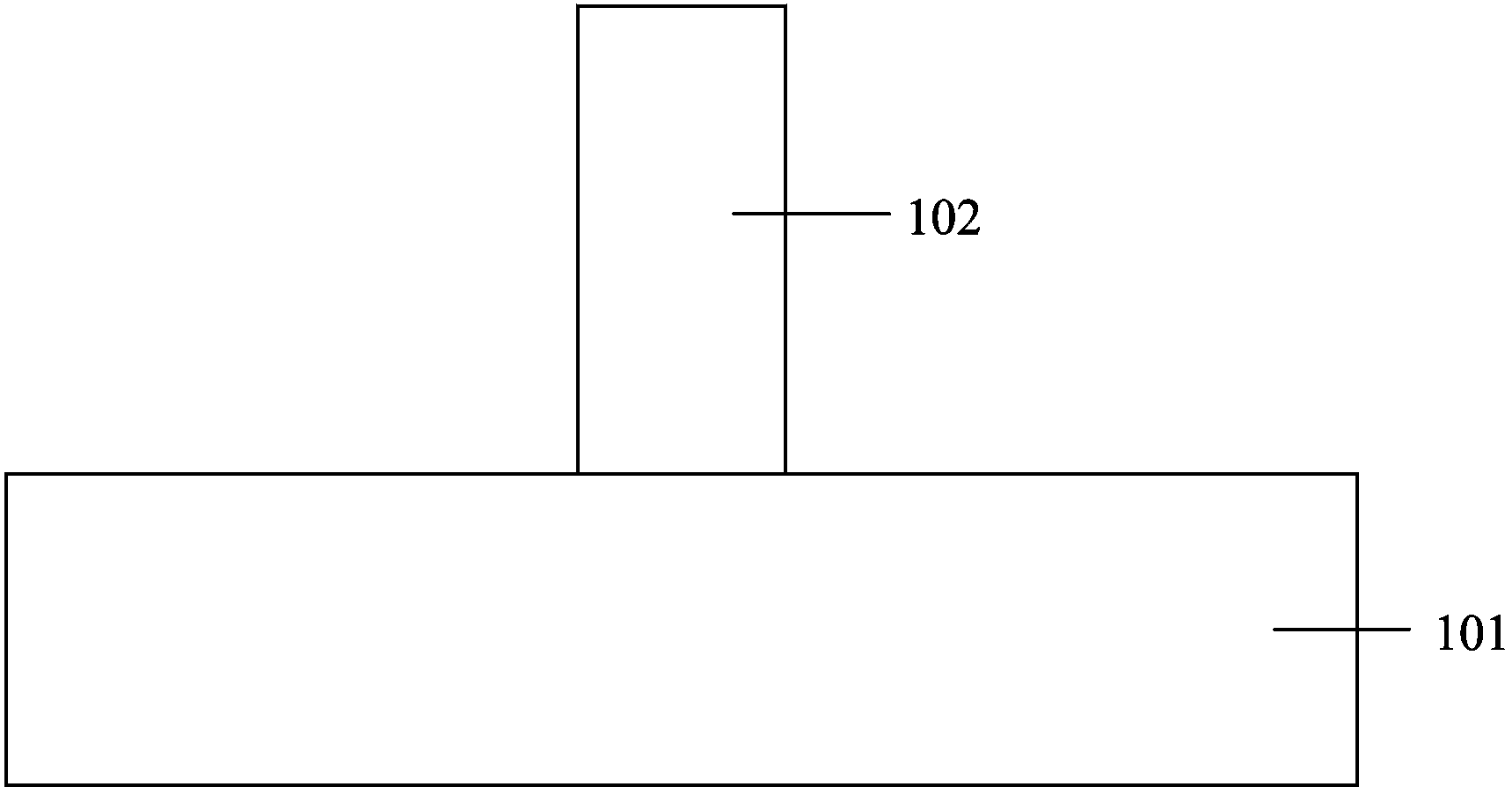

[0055] first reference Figures 4A-4C , providing a substrate 201; forming a fin portion 202 doped with impurities on the substrate 201 as a base region, and the fin portion 202 includes a first region 2021 and a second region 2023 separated from each other.

[0056] Figure 4A is a schematic diagram of a three-dimensional structure of a fin 202 doped with impurities formed on a substrate 201, Figure 4B for Figure 4A The sectional view of the plane cut by the median line A-A', Figure 4C for Figure 4A Sectional view of the plane cut by the median line B-B'.

[0057] In a speci...

no. 2 Embodiment

[0076] This embodiment is an embodiment of a fin bipolar junction transistor.

[0077] refer to Figures 5A-6B , the fin bipolar junction transistor includes: a substrate 201; a fin 202 located on the substrate 201, the fin 202 is a base region; the fin 202 includes a first region 2021 and a second region separated from each other A region 2023; a collector region located on the first region 2021; an emission region located on the second region 2023.

[0078] refer to Figure 6A and 6B , the fin portion 202 further includes a third region 2022 located between the first region 2021 and the second region 2023 .

[0079] In a specific embodiment, the material of the substrate 201 may be silicon, silicon germanium, silicon-on-insulator, and in other embodiments, it may also be other conventional semiconductor materials well known in the art.

[0080] In a specific embodiment, the fin bipolar junction transistor is a PNP transistor, the material of the fin portion 202 is SiC, a...

no. 3 Embodiment

[0084] This embodiment will describe in detail the method of fabricating a fin bipolar junction transistor.

[0085] Figure 7A to Figure 8B It is the structure schematic diagram of the preparation fin bipolar junction transistor of this specific embodiment, will combine below Figure 7A to Figure 8B , the technical solution of the present invention will be described in detail.

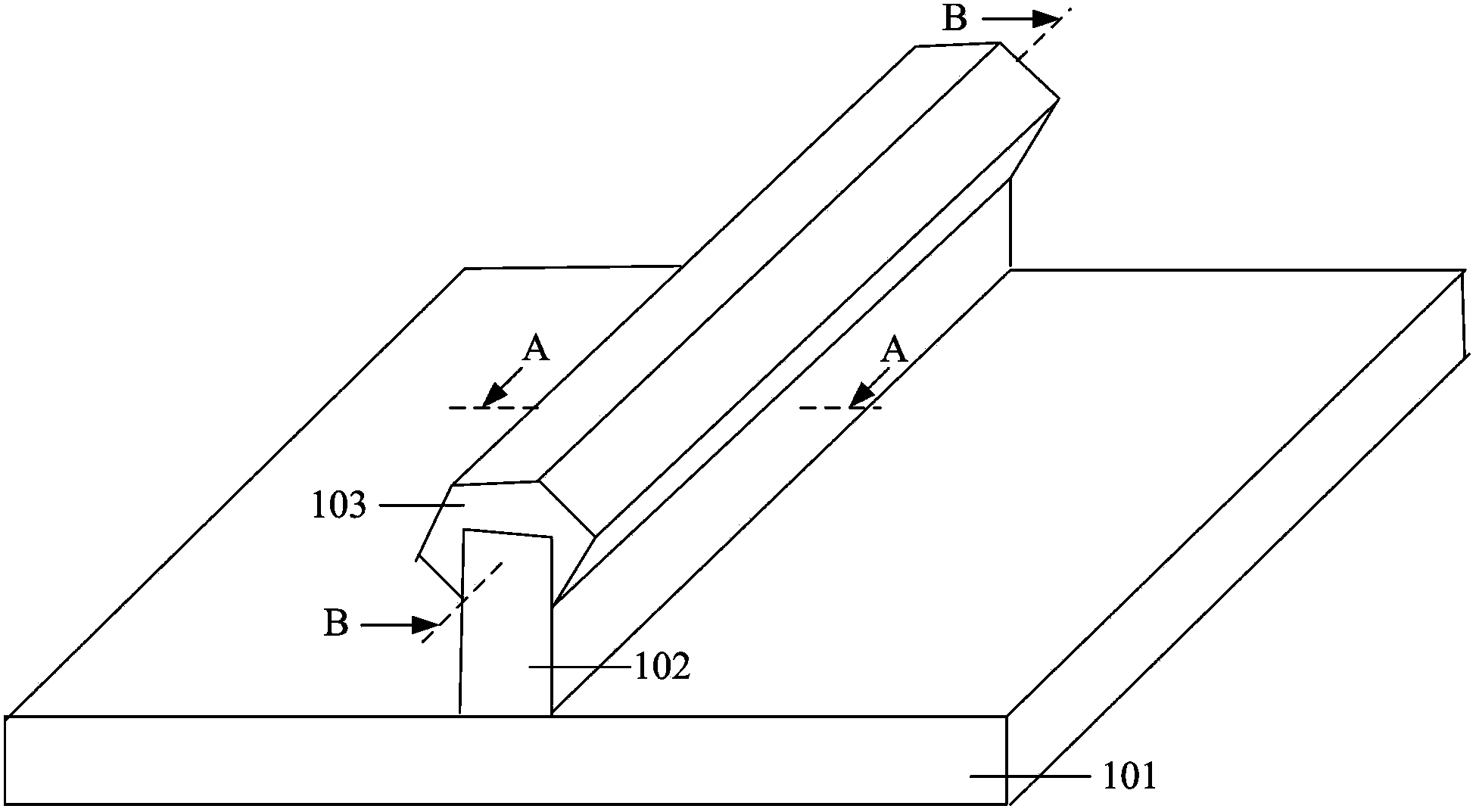

[0086] first reference Figures 7A-7C , providing a substrate 301; forming a fin 302 doped with impurities on the substrate 301 as an emission region, and the fin 302 includes a first region 3021 and a second region 3022 in contact with each other.

[0087] In a specific embodiment, the total length of the first region 3021 and the second region 3022 is smaller than the length of the fin 302, so as to reserve a space on the fin 302 and form a contact electrode on the fin 302; if There is no need to reserve space for the formation of contact electrodes, and the total length of the first region 3021 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com