Method for preparing hydrophobic paper

A paper and hydrophobic technology, which is applied in papermaking, paper coating, physical treatment of paper, etc., can solve the problems of low melting point and limited temperature range of hydrophobic paper, and achieve the effects of simplified processing technology, low price and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

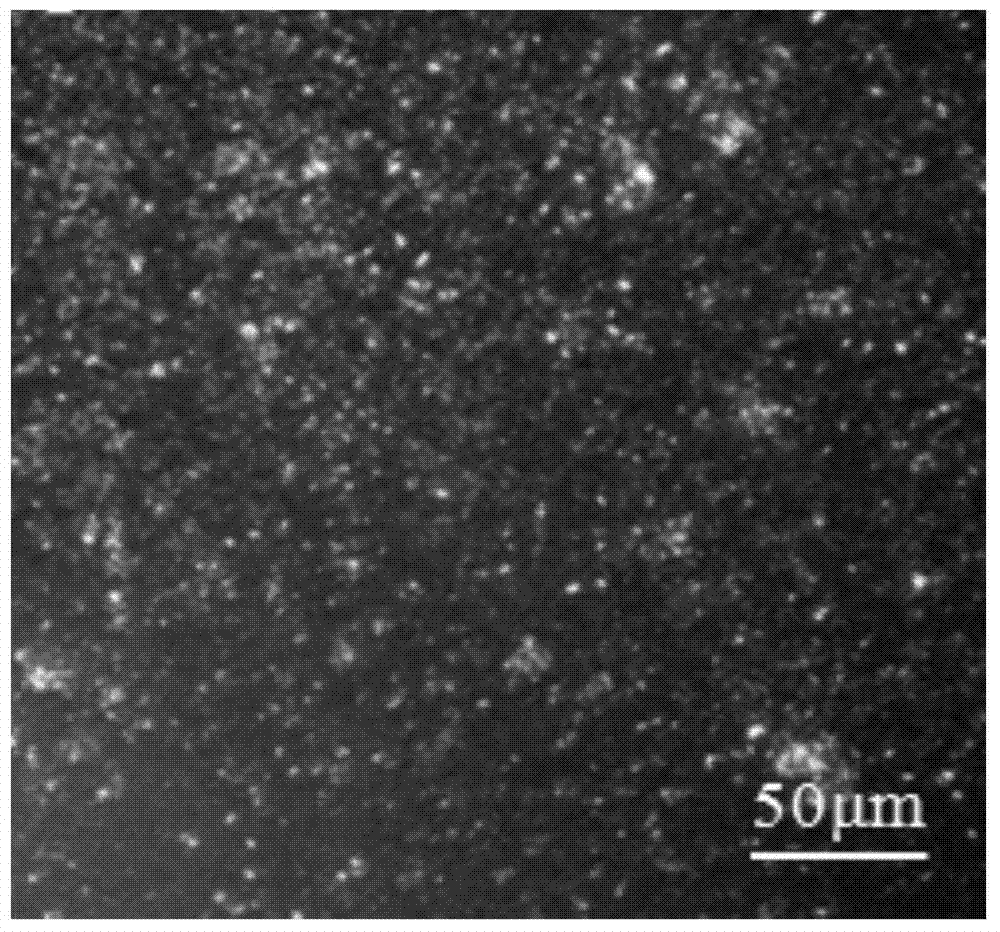

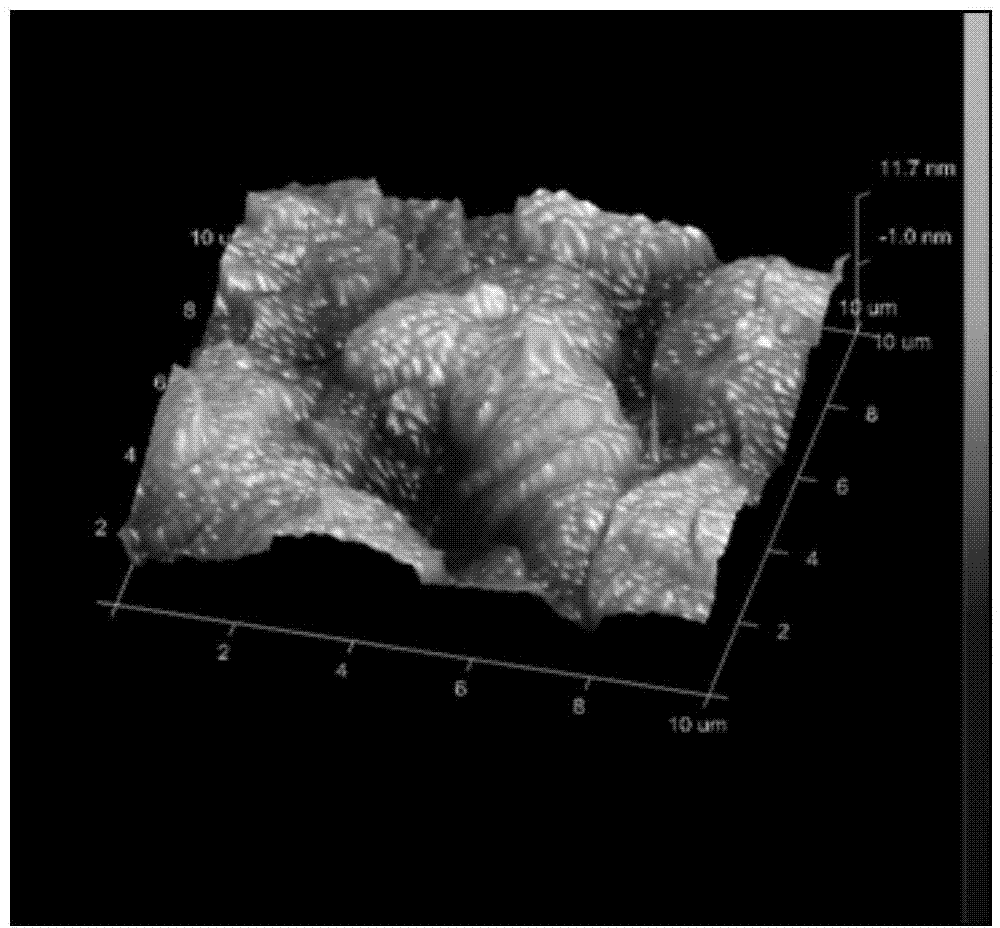

Image

Examples

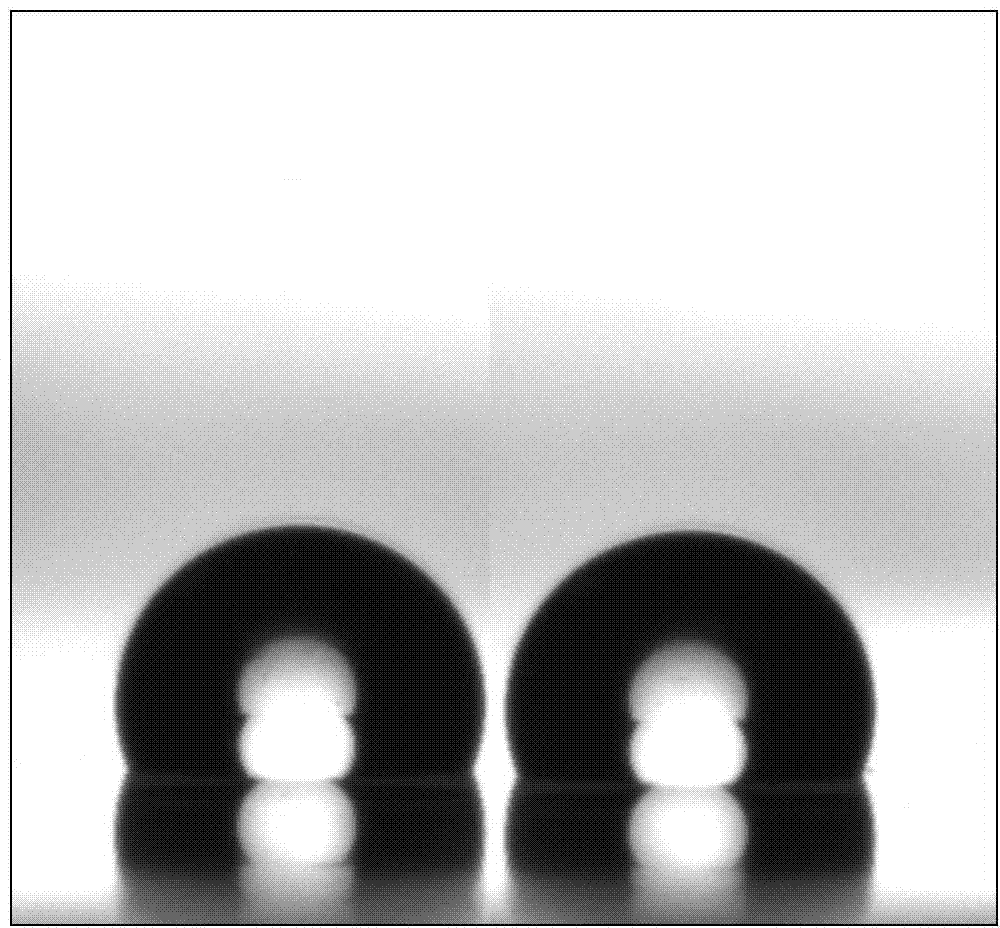

Embodiment 1

[0045] First add WPP (industrial grade, Jiangyin Jiuli Plastic Industry Co., Ltd.) and toluene into a four-necked flask with a stirring and reflux device at a mass ratio of 1:3, heat at 115±5°C, and fully dissolve to obtain a WPP solution. Then, at 90±2°C, the initiator 2.5wt% BPO was dissolved in toluene to obtain a BPO toluene solution, which was then added dropwise into the WPP solution. Then, methacrylic acid (MAA) mixed with toluene at a mass ratio of 1:1 to WPP was added dropwise into a four-necked flask, and the constant temperature reaction was continued for 2 hours to obtain a MWPP solution. The Span80 (pharmaceutical grade, Shanghai Jingchun Industrial Co., Ltd.) of 5wt% is joined in the MWPP mixed solution; In another four-necked flask with stirrer, add water, 10wt% Tween20 (chemically pure, Wenzhou Qingming Chemical Industry Co., Ltd. Co., Ltd.) and 4wt% organic amine, heated to 90±5°C. Slowly add the MWPP solution into the aqueous solution, and stir rapidly. Afte...

Embodiment 2

[0047] Similar to the method in Example 1, the difference is that the mass ratio of MAA to WPP is 1.1:1, and the obtained hydrophobic paper is measured by a contact angle tester, and the surface water contact angle of the hydrophobic paper is 117±1°.

Embodiment 3

[0049] Similar to the method in Example 1, the difference is that the mass ratio of MAA to WPP is 1.2:1, and the obtained hydrophobic paper is measured by a contact angle tester, and the surface water contact angle of the hydrophobic paper is 115±2°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com