Process for removing heavy metal ions in wastewater through pressurized dissolved air flotation method and device thereof

A technology of heavy metal ions and pressurized dissolved gas, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , the low efficiency of removing heavy metals, etc., to achieve the effect of improving the technical content, realizing the reuse of resources, and improving the efficiency of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

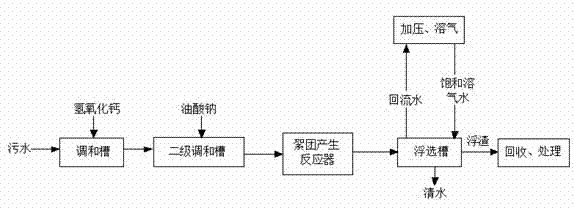

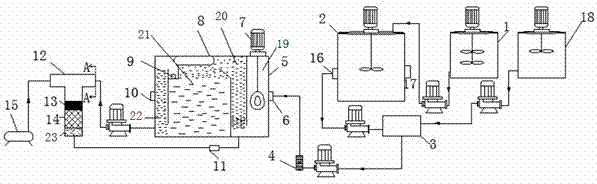

[0029] The technical process of removing heavy metal ions in waste water by pressurized dissolved air method described in this embodiment includes the following steps, such as figure 1 Shown:

[0030] In this example, waste water from Huize, Yunnan Province is used as the treatment object, and the waste water mainly contains pb 2+ , Zn 2+ , algae and other substances of which pb 2+ , Zn 2+ The contents were 1.5mg / L and 3.2mg / L respectively.

[0031](1) First pass calcium hydroxide into the wastewater at a ratio of 1.5g / L to neutralize the acidic ions in the wastewater, and then introduce sodium oleate at a ratio of 25mg / L to make the formed precipitate hydrophobic and achieve The wastewater was pretreated, and the pH value was adjusted to 8.5 with calcium carbonate, and the residence time was 60 min.

[0032] (2) Compressed air and return water are made into high-pressure dissolved air water.

[0033] (3) Pass the high-pressure dissolved air water into the pretreated was...

Embodiment 2

[0041] In this embodiment, waste water from Chihong, Yunnan is used as the treatment object, and the waste water mainly contains Zn 2+ , algae and other substances in which Zn 2+ 、Cd 2+ The contents were 4.5mg / L and 2.5mg / L respectively.

[0042] The simultaneous desulfurization, denitrification and demercuration dry flue gas purification process described in this embodiment includes the following steps:

[0043] (1) First pass calcium hydroxide into the wastewater at a ratio of 40kg / t to neutralize the acid ions in the wastewater, and then introduce sodium oleate at a ratio of 120kg / t to make the formed precipitate hydrophobic and achieve The wastewater was pretreated, and the pH value was adjusted to 10 with calcium carbonate, and the residence time was 60 min.

[0044] (2) Compressed air and return water are made into high-pressure dissolved air water.

[0045] (3) Pass the high-pressure dissolved air water into the pretreated wastewater obtained in step (1) according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com