Method for recycling waste rigid polyurethane foam plastics and waste spandex filaments

A rigid polyurethane, polyurethane foam technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of no progress, complicated operation, too complicated, etc., and achieve the effect of low cost, simple process and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

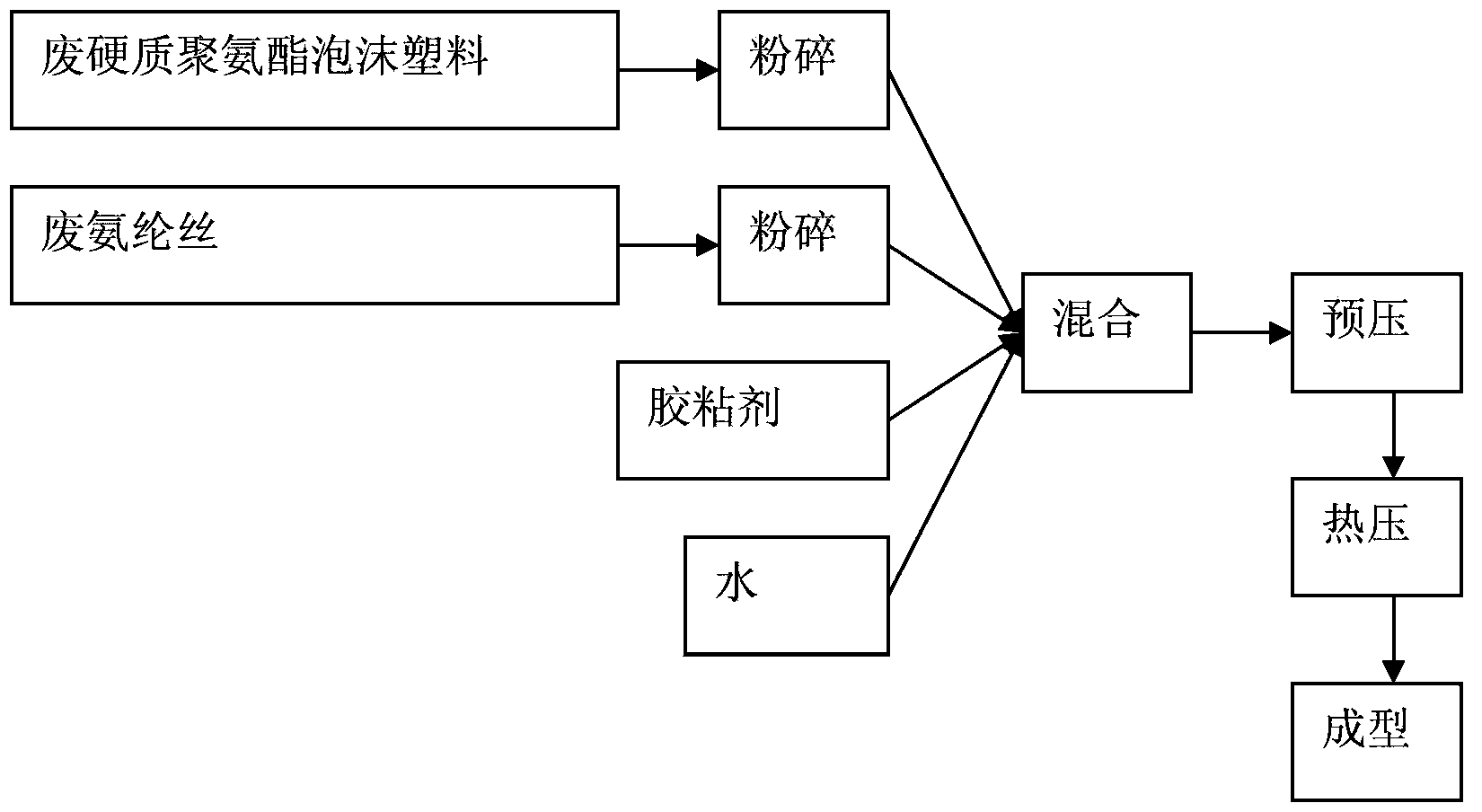

Method used

Image

Examples

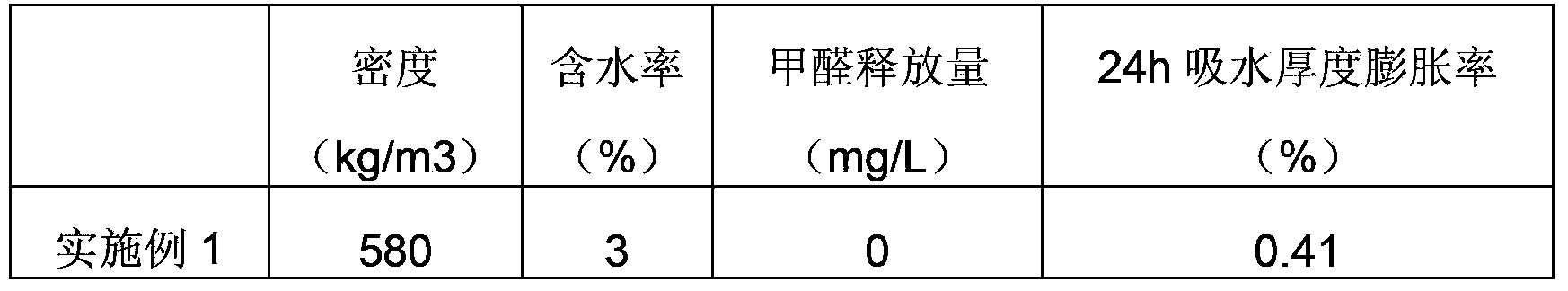

Embodiment 1

[0038] The waste rigid polyurethane foam is crushed and impurities are removed to obtain foam particles with a size of 1-5mm. Weigh 95kg;

[0039] Crush the waste spandex filaments and remove impurities to obtain short spandex filaments with a size of 1 to 5 cm, weighing 5 kg;

[0040] Pour the foam particles and short spandex filaments into the mixer, add 12kg of polyurethane glue and stir thoroughly, during the stirring process, spray 1kg of water with a sprayer;

[0041] Pour the fully stirred mixture with adhesive and water into a container with a length of 2.7 meters, a width of 1.5 meters and a height of 0.5 meters. After being pressed by rollers, it is sent to a hot press for hot pressing. Wherein, the temperature of the hot press forming is 150° C., the pressure is 120 bar, and the holding time is 10 minutes.

[0042] The applied pressure is unloaded, the board is demoulded and taken out to obtain the rough embryo of the polyurethane imitation wood board, and then af...

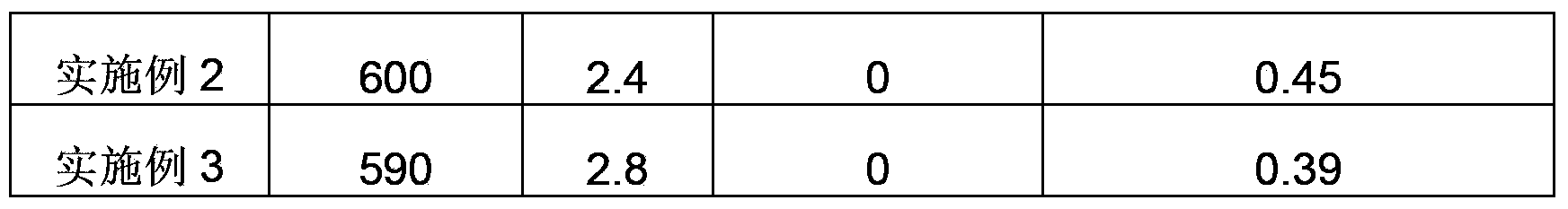

Embodiment 2

[0044] The waste rigid polyurethane foam is crushed and impurities are removed to obtain foam particles with a size of 1-5mm. Weigh 90kg;

[0045] Crush the waste spandex filaments and remove impurities to obtain short spandex filaments with a size of 1 to 5 cm, weighing 10 kg;

[0046] Pour the foam particles and short spandex filaments into the mixer, add 10kg of polyurethane glue and stir thoroughly, during the stirring process, spray 3kg of water with a sprayer;

[0047] Pour the fully stirred mixture with adhesive and water into a container with a length of 2.7 meters, a width of 1.5 meters and a height of 0.5 meters. After being pressed by rollers, it is sent to a hot press for hot pressing. Wherein, the temperature of the hot press forming is 150° C., the pressure is 130 bar, and the holding time is 10 minutes.

[0048] The applied pressure is unloaded, the board is demoulded and taken out to obtain the rough embryo of the polyurethane imitation wood board, and then a...

Embodiment 3

[0050] The waste rigid polyurethane foam is crushed and impurities are removed to obtain foam particles with a size of 1-5mm. Weigh 85kg;

[0051]Crush the waste spandex filaments and remove impurities to obtain short spandex filaments with a size of 1 to 5 cm, weighing 7 kg;

[0052] Pour the foam particles and short spandex filaments into the mixer, add 8kg of polyurethane glue and stir thoroughly, during the stirring process, spray 3kg of water with a sprayer;

[0053] Pour the fully stirred mixture with adhesive and water into a container with a length of 2.7 meters, a width of 1.5 meters and a height of 0.5 meters. After being pressed by rollers, it is sent to a hot press for hot pressing. Wherein, the temperature of the hot press forming is 150° C., the pressure is 120 bar, and the holding time is 15 minutes.

[0054] The applied pressure is unloaded, the board is demoulded and taken out to obtain the rough embryo of the polyurethane imitation wood board, and then thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com