Preparation method of artificial ligament modified by strontium/silk protein biomimetic coating

An artificial ligament and silk protein technology, applied in the field of biomedicine, can solve the problems of poor tendon-bone healing and low degree of healing between artificial ligament and tendon-bone, and achieve the effect of solving uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Under the protection of nitrogen, with water as solvent, 0.1ml of 1mmol / L SrNO 3 Mix with 1ml of 50mM natural silk protein solution, adjust the pH value to 8, and stir at 25°C for 5min. 10 x 10 in background vacuum -5 Pa, power 50W, use H 2 The artificial ligament material was treated with plasma for 60 minutes, then washed with pure water and dried in vacuum to obtain the pretreated artificial ligament material.

[0035] Then soak the artificial ligament in the strontium-containing silk protein mixture, and stir for 30 minutes. Fully combine the free strontium ions in the system with the amino residues of silk protein, then take out the filter paper and blot dry, then soak in 1ml of 50mM silk protein solution, react at 25°C for 5min, repeat the above steps 5 times to obtain strontium / silk protein Novel artificial ligament modified with biomimetic coating.

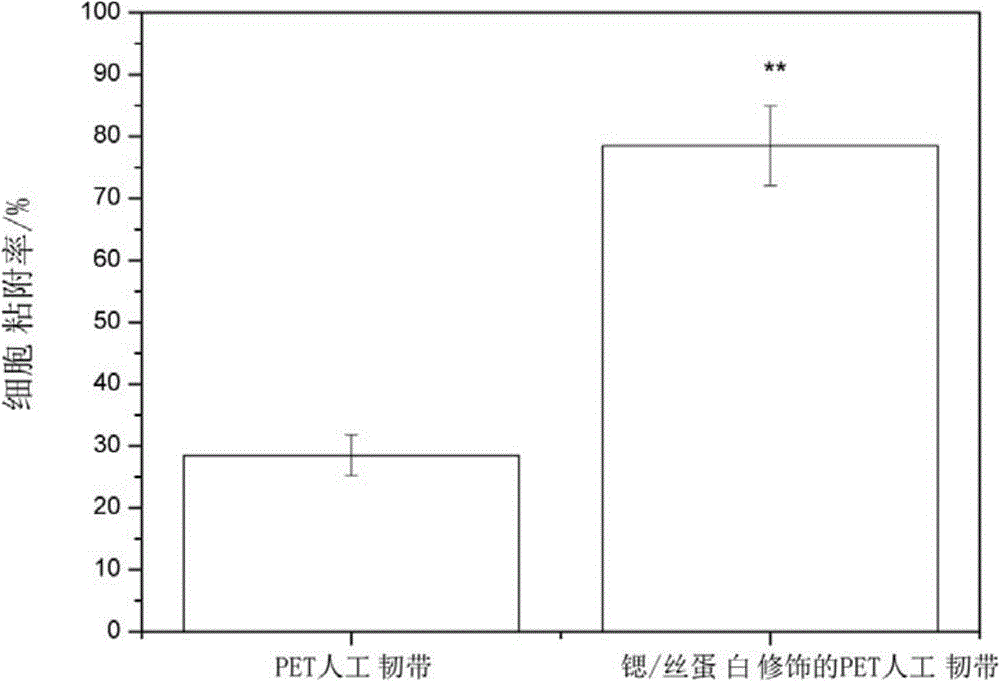

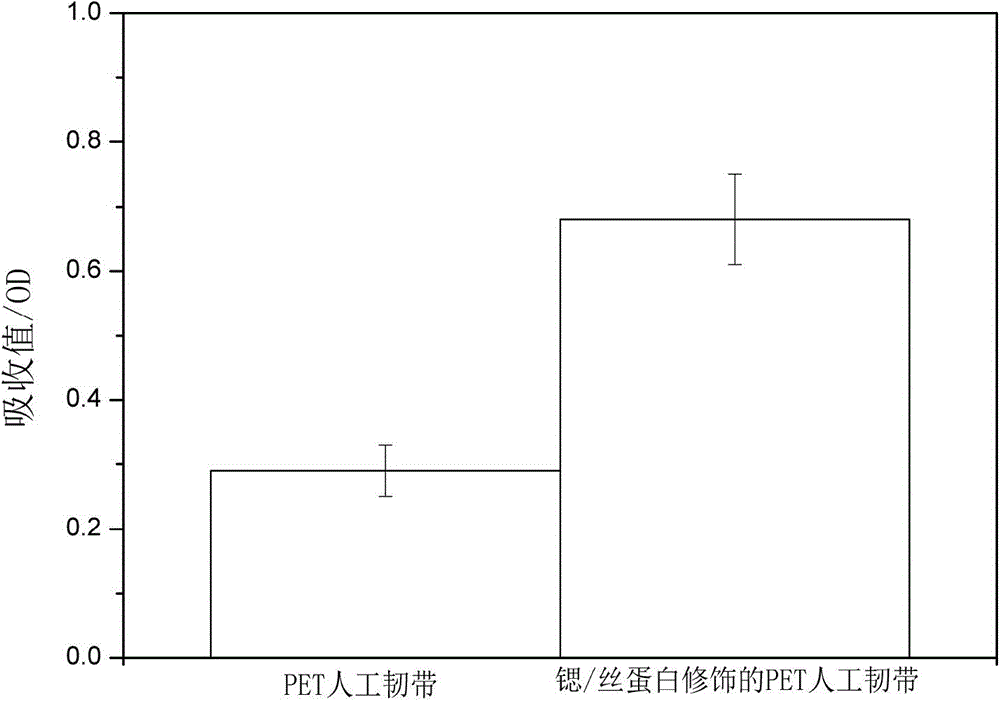

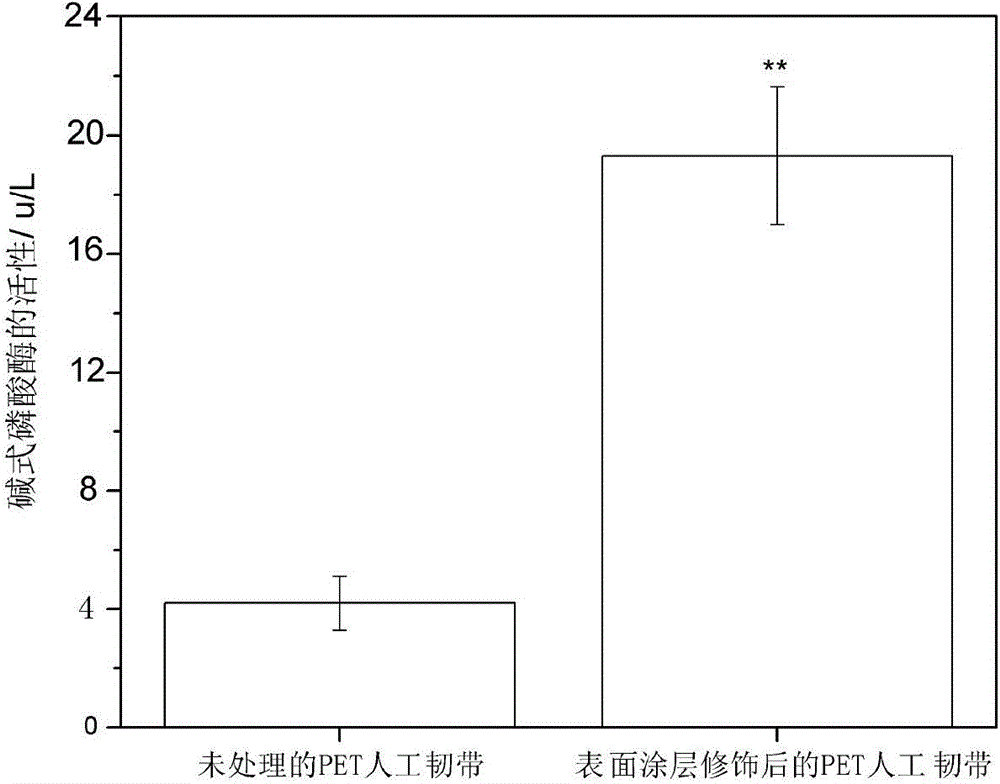

[0036] Among them, the biological evaluation of the new artificial ligament modified by the obtained hydroxya...

Embodiment 2

[0042] Using water as a solvent, mix 1ml of 10mmol / L strontium chloride with 100ml of 100mM recombinant silk protein solution, adjust the pH value to 7.4, stir for 45 minutes at 25 degrees Celsius, and vacuum at 10×10 -5 Pa, power 100W, use N 2 The PET artificial ligament was treated with plasma for 60 minutes, then washed with pure water and dried in vacuum; then the artificial ligament was soaked in the mixture, and stirred for 20 minutes. Fully combine the free Si ions in the system with the amino residues of silk protein, then take out the filter paper to dry, and finally soak in 100 ml of 100mM recombinant silk protein solution, stir and react at 25 degrees Celsius for 45 minutes, repeat the above steps 30 times, A new artificial ligament modified with hydroxyapatite-doped strontium composite silk protein mineralization coating was obtained.

Embodiment 3

[0044] Under normal temperature and pressure, mix 0.5 ml of a mixture of 5 mM strontium nitrate and strontium chloride with 25 ml of 85 mM natural silk protein and recombinant silk protein mixed solution at 25 degrees Celsius for 15 minutes, adjust the pH value to 7.6, in this Bottom Vacuum 10×10 -2 Pa, power 80W, use O 2 Treat the PET artificial ligament with plasma for 30 minutes, then wash it with pure water and dry it in vacuum; then soak the artificial ligament in this mixture, stir and react for 25 minutes, so that the free Si ions in the system can fully combine with the amino residues of silk protein, and then Take out the filter paper to dry, and finally soak in 50 ml of 85mM silk protein solution, stir and react at 25 degrees Celsius for 15 minutes, repeat the above steps 15 times, and obtain a new type of artificial hydroxyapatite-doped strontium composite silk protein mineralization coating modification. ligament.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com