Cold-box binding agent systems and mixtures for use as additives for such binding agent systems

A technology of mixtures, binders, applied in the application of additives, moulds or cores for casting, solutions containing polyisocyanates, in the field of manufacturing cores or moulds for casting, able to solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0167] Example 1: Preparation of mixture M1 according to the invention :

[0168] The following substances were dispensed in the order indicated in a reaction vessel equipped with a stirrer, cooling device and thermometer, wherein the temperature was kept below 35°C:

[0169]

[0170] The product is a mixture according to the invention.

[0171] Example 1a: Preparation of mixture M2 according to the invention :

[0172] The following substances were dispensed in the order indicated in a reaction vessel equipped with a stirrer, cooling device and thermometer, wherein the temperature was kept below 35°C:

[0173]

[0174] The product is a mixture according to the invention.

[0175] Example 1b: Preparation of mixture M3 according to the invention :

[0176] The following substances were dispensed in the order indicated in a reaction vessel equipped with a stirrer, cooling device and thermometer, wherein the temperature was kept below 35°C:

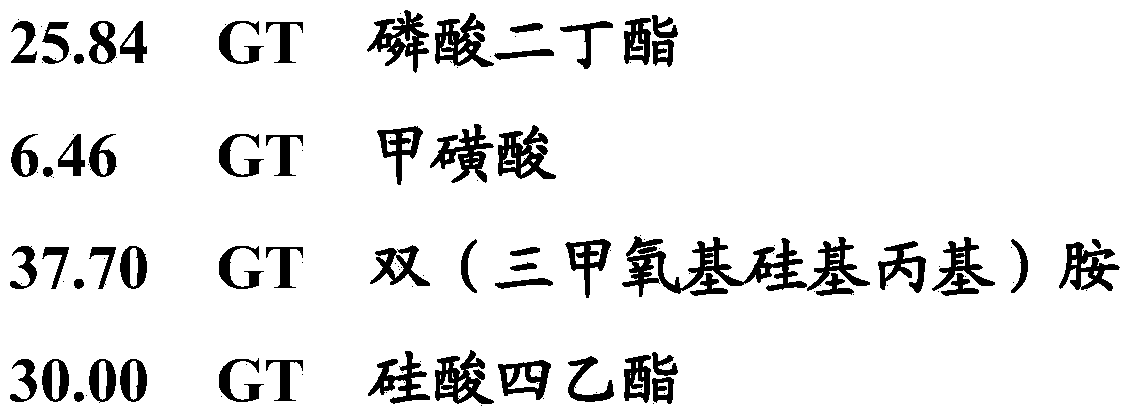

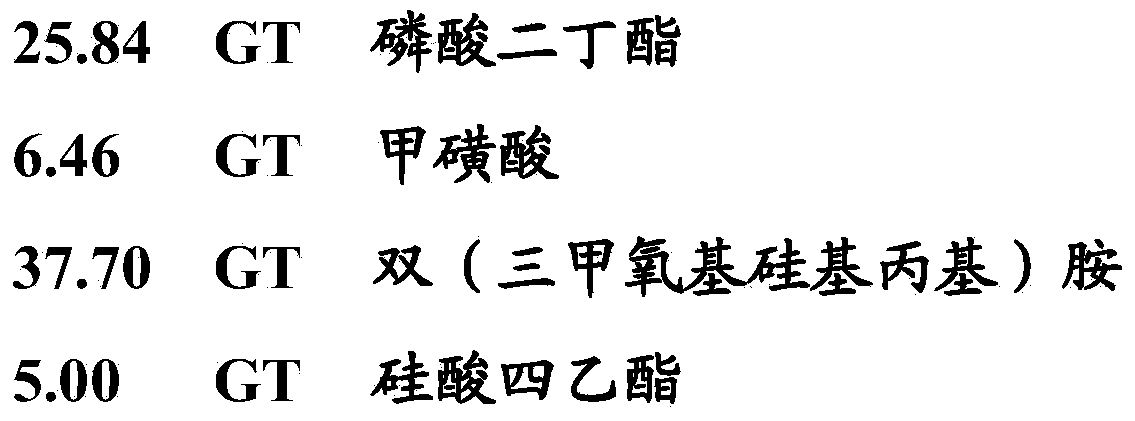

[0177] 25.84 GT Dibuty...

example 2

[0181] Example 2: Preparation of preferred benzyl ether type phenolic resins (precondensates) :

[0182] Place the following in a reaction vessel equipped with a cooling device, thermometer and stirrer:

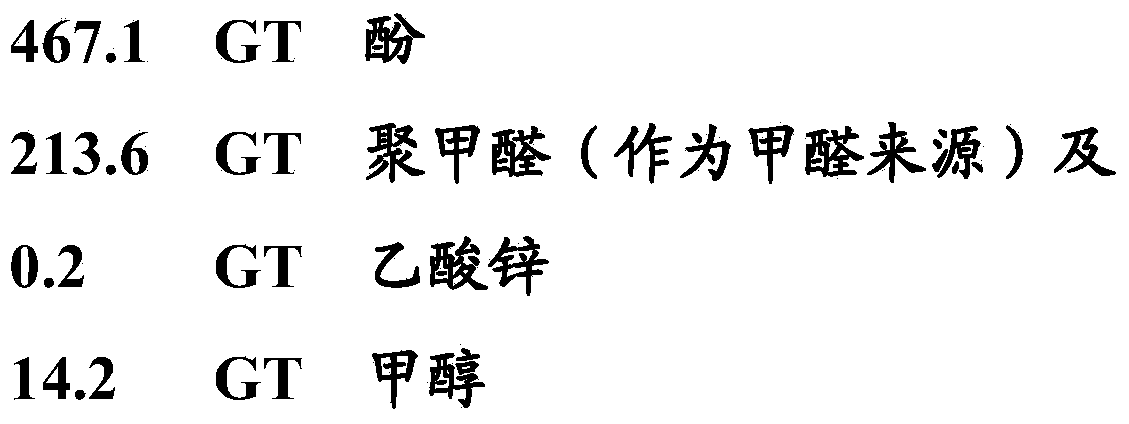

[0183]

[0184] Put the cooler on reflux. The temperature was continuously increased to 110 °C within 1 hour and maintained at said temperature until the refractive index (n D 20 ) to 1.547 (2 to 3 hours).

[0185] Then, the cooler was switched to atmospheric distillation and the temperature was increased to 125°C-126°C within 1 hour, so that volatile components were distilled from the product solution until the refractive index of the product (n D 20 ) reaches about 1.595.

[0186] Then carry out vacuum distillation, until the refractive index (n D 20 ) is 1.617, where the remaining volatile components are removed.

example 3

[0187] Example 3: Preparation of cold box phenolic resin solution H1 :

[0188]From the phenolic resin (precondensate) according to Example 2, after reaching the desired value for the refractive index, a resin solution H1 for the cold box process was prepared, which solution had the composition specified below:

[0189] Phenolic resin solution H1

[0190]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com