High-performance band-shaped transmission line guide mechanism

A strip transmission line, high-performance technology, applied in the direction of waveguide, waveguide-type devices, circuits, etc., can solve the problems of poor microwave high-frequency transmission characteristics, low guidance accuracy, etc., to reduce the influence of microwave characteristic impedance, improve the guide Improves accuracy and prolongs mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

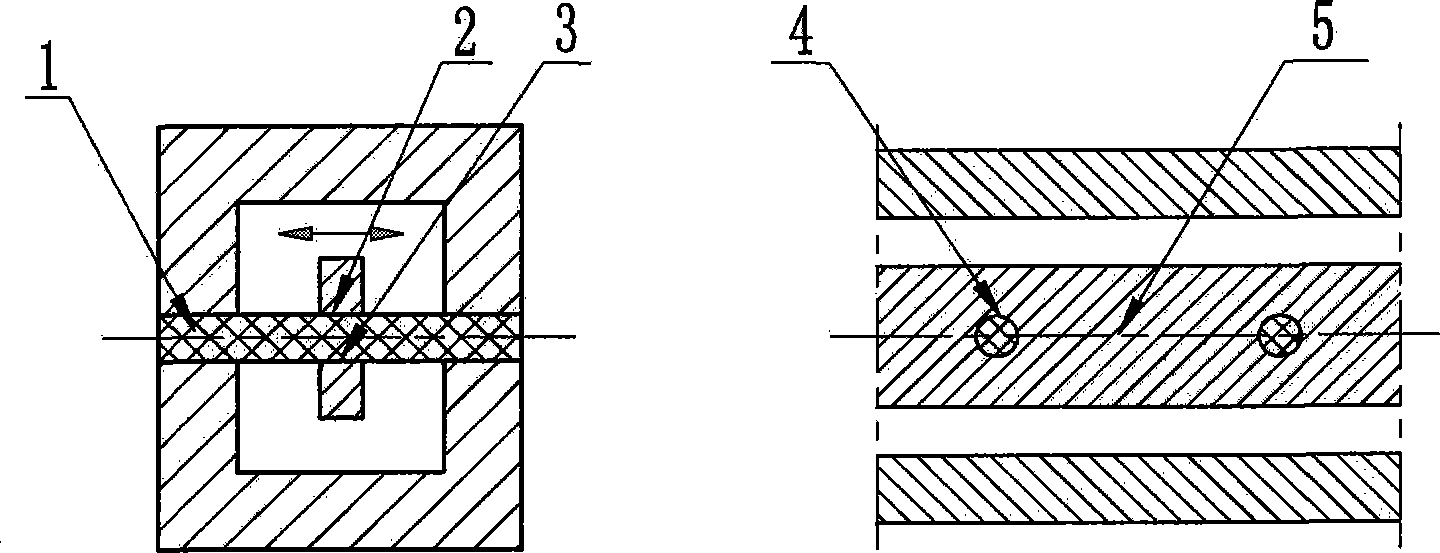

[0015] Such as figure 1 , 2 As shown, the present invention provides a high-performance strip transmission line guiding mechanism, which is mainly embodied in 1 guiding post, 2 guiding holes, and 6 sheet-shaped central conductors.

[0016] Such as figure 1 As shown, 1. The guide post is made of high-temperature-resistant plastic with good wear resistance and low thermal expansion coefficient; 3. The thermal expansion gap is reduced; 4. The guide hole and guide post; 5. The axis of the central conductor.

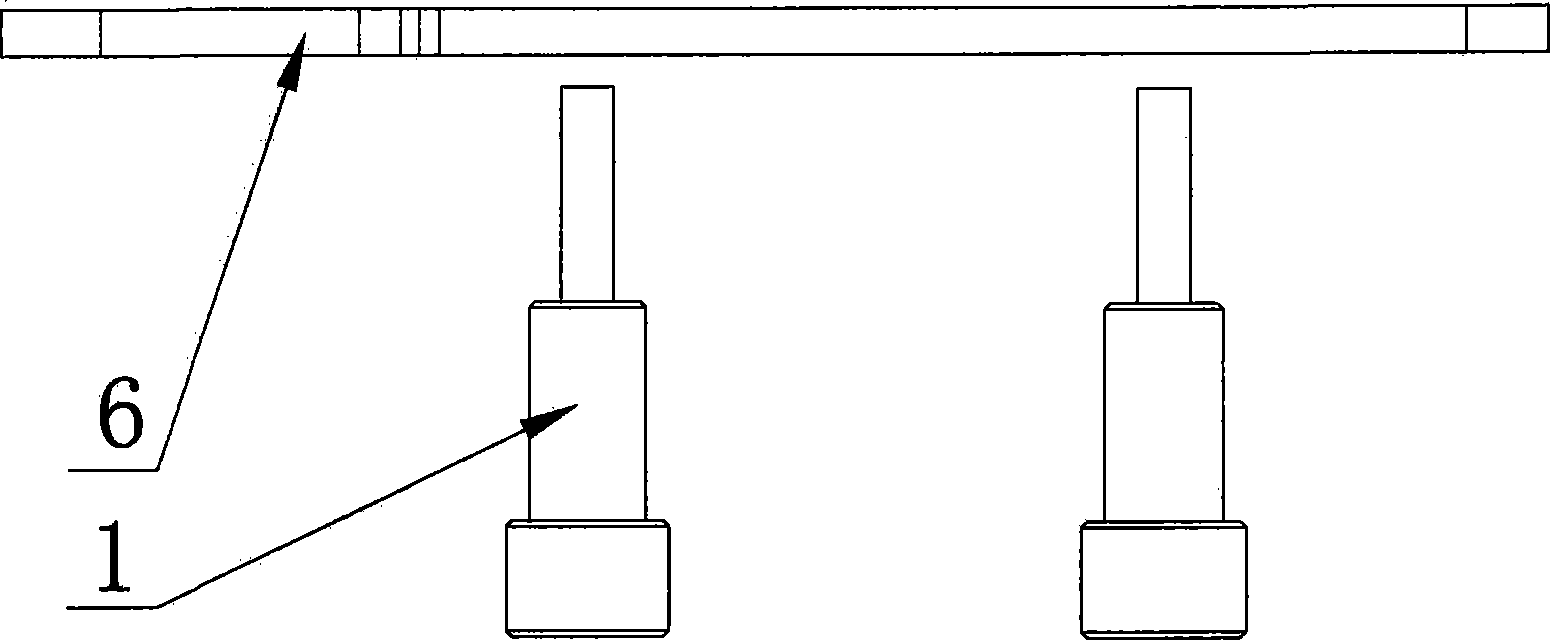

[0017] Such as figure 2 As shown, 1 guide post passes through 2 guide holes on the 6 sheet center conductors.

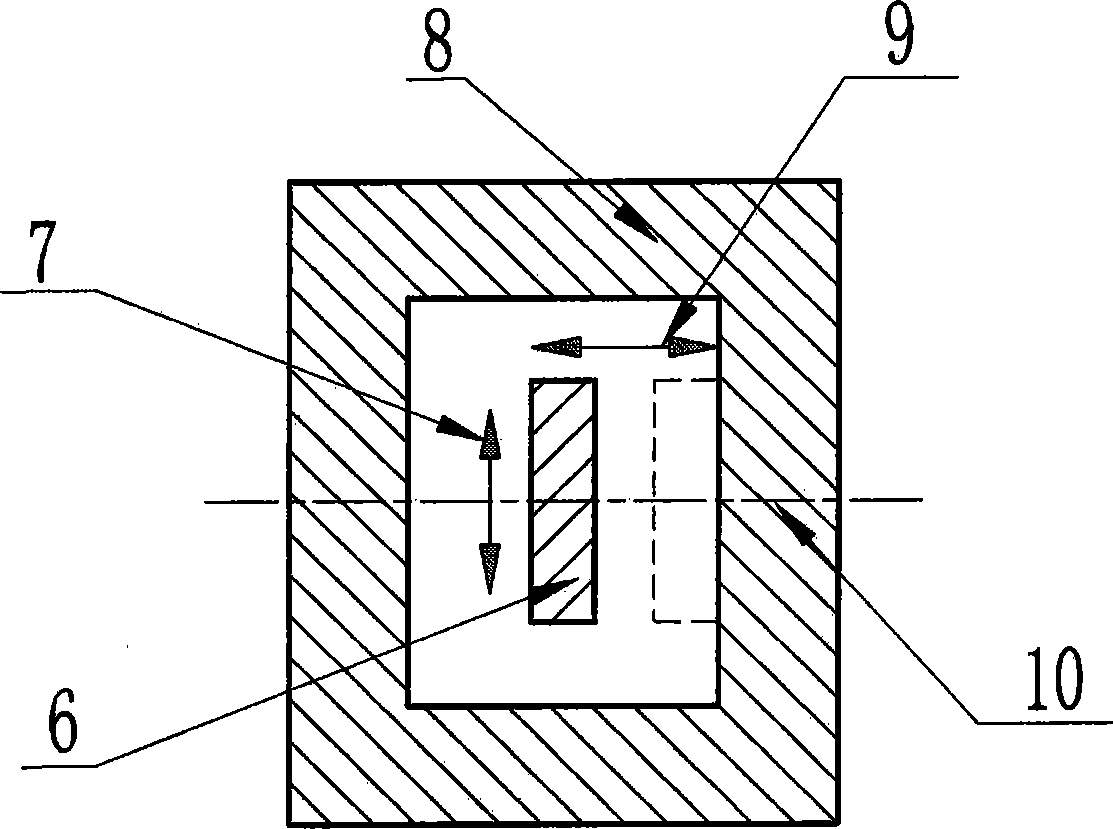

[0018] Such as image 3 As shown, 7 represents lateral movement; 8 represents the rectangular outer conductor; 9 represents translation between the center of the rectangular external conductor and the sidewall; 10 represents the common symmetrical center.

[0019] Such as Figure 5 As shown, 11 represents the thermal expansion gap.

[0020] The content that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com