System and method for managing steel billets in heating furnace

A management system and heating furnace technology, which is applied in the field of management system of steel billets in heating furnaces, can solve problems such as large errors, errors, and difficulty in controlling the energy consumed by billet heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

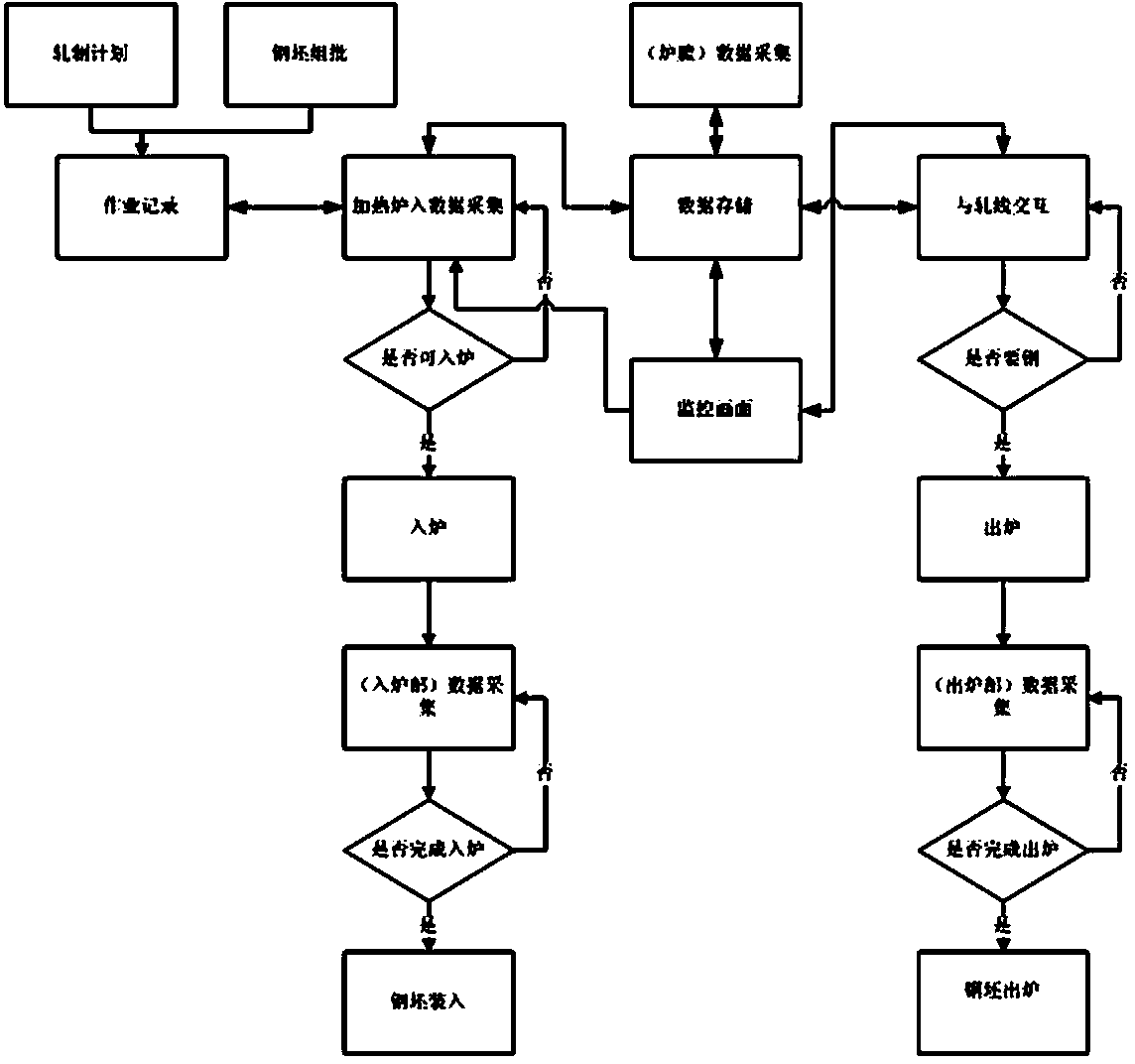

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

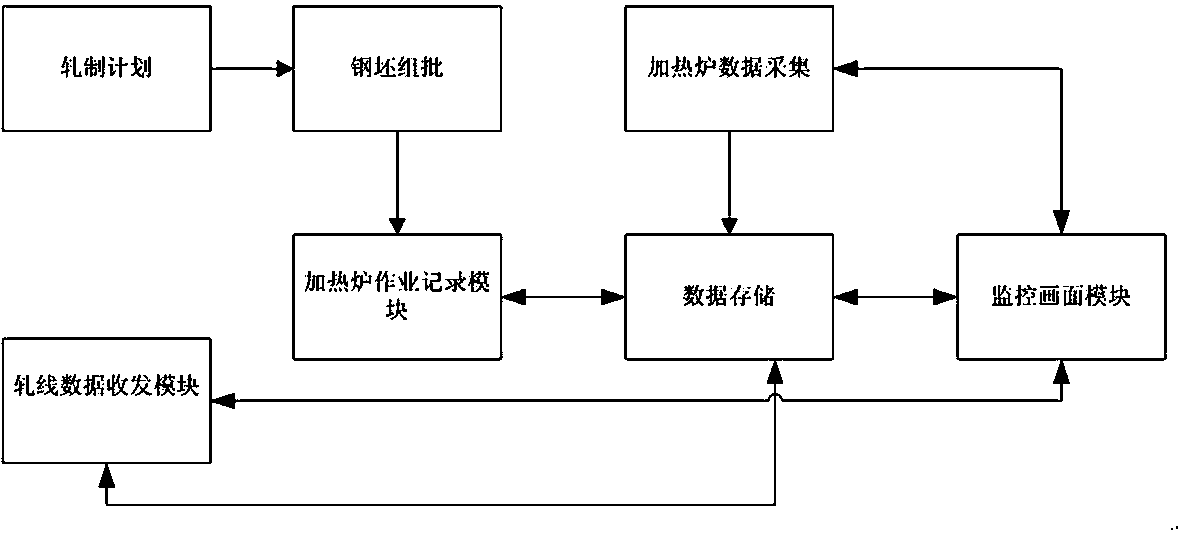

[0024] The billet management system in the heating furnace of the present invention includes a planning module, a batch module, a data acquisition module, a data storage module, a picture generation module, a data recording module, and a data sending and receiving module, wherein:

[0025] Planning module: used to make the rolling plan according to the order, and record the steel slabs that will enter the heating furnace for heating;

[0026] Batching module: used for steel slabs to enter the heating furnace in batches for heating, and the steel slabs in each batch enter the heating furnace in sequence and come out of the furnace in sequence;

[0027] Data acquisition module: used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com