Forklift type stoking trolley

A forklift type, forklift technology, applied in furnaces, furnace components, lifting devices, etc., can solve the problems of large production costs, waste, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a forklift type furnace pounder, which has strong maneuverability, flexible operation, high work efficiency and low use cost.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

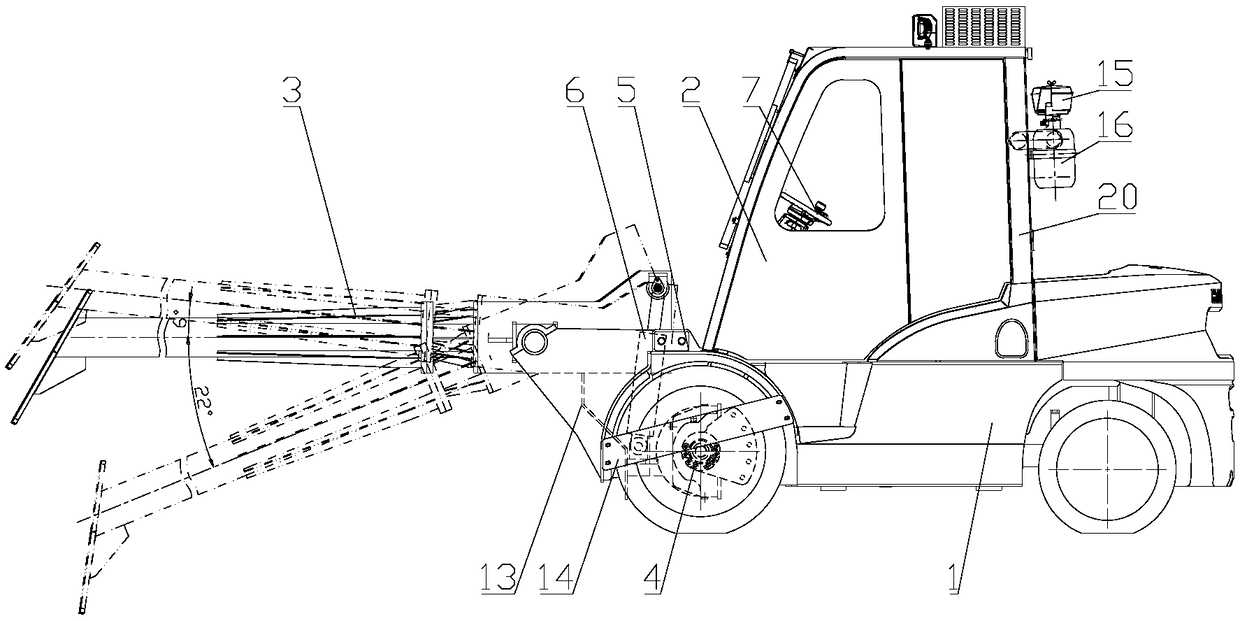

[0024] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the forklift type furnace pounder provided by the present invention.

[0025] The forklift type furnace pounder provided by the specific embodiment of the present invention is transformed from an existing forklift, and specifically includes a forklift body 1, a cab 2 arranged on the forklift body 1 and a front end of the forklift body 1. Furnace pounding mechanism 3, wherein, the forklift-type furnace pounding vehicle utilizes the forklift truck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com