Upper repairing method for mammoth converter lining

A technology for large-scale converters and converter linings, which is applied in the manufacture of converters, etc., can solve the problems of prolonged furnace life and high equipment costs, and achieves stable equipment performance, safe operation, and good versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

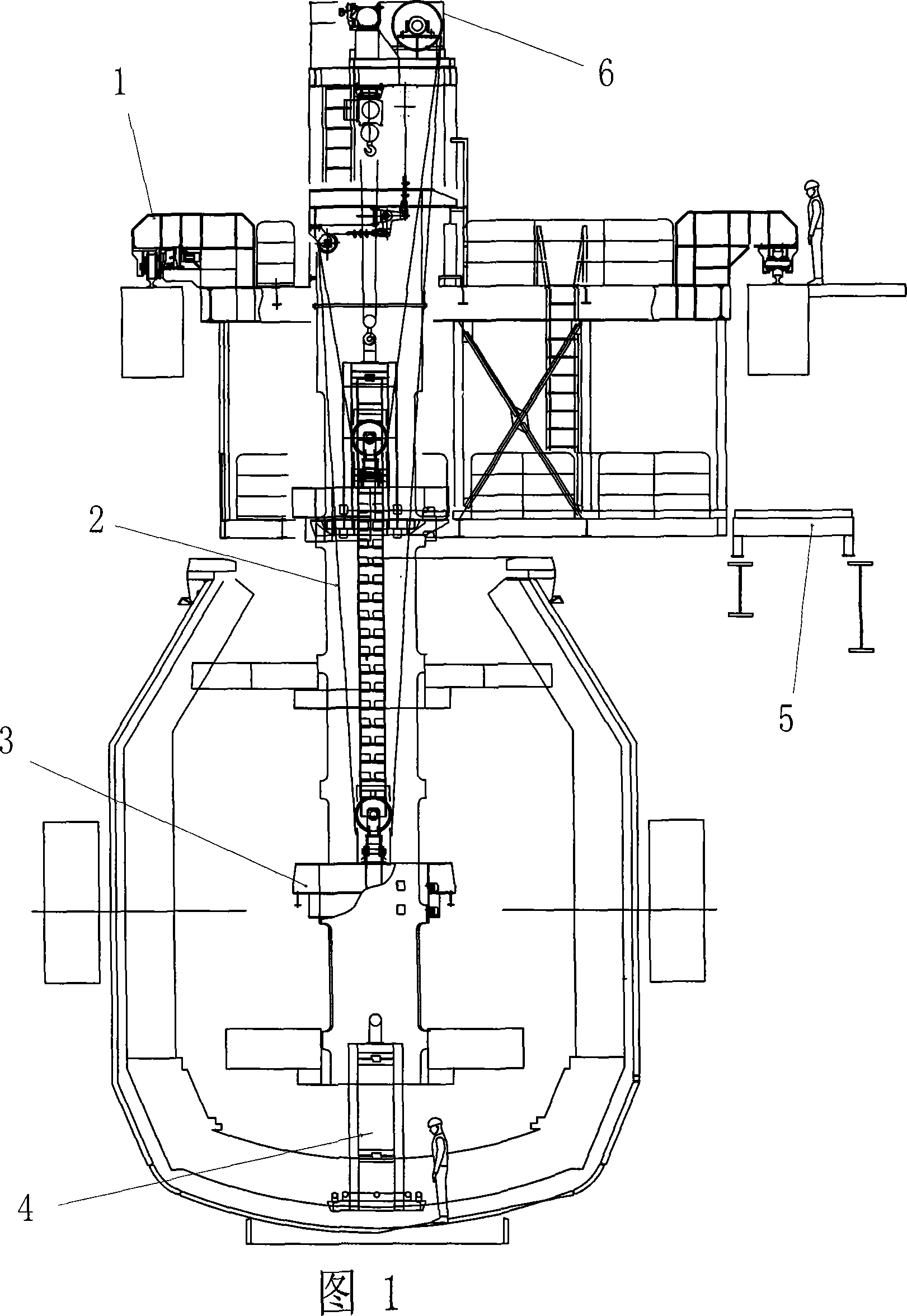

Image

Examples

Embodiment Construction

[0014] In the present invention, taking the repair of the lining of a 300t converter as an example, the repairing method includes the following steps:

[0015] Step 1: First, drive out the fume hood mobile trolley with the mobile fume hood and fume hood skirt installed on the furnace mouth of the converter, move it to the standby position, and then drive the positioning trolley for the furnace tower system to the working position, that is, the converter The positioning is fixed directly above the center line;

[0016] Step 2: Use the special crane for oxygen lance maintenance to hoist the furnace repair tower body from the storage position to the converter repair work position, and position, connect and fix it on the furnace repair tower trolley;

[0017] Step 3: The operator on the platform of the fume hood moving trolley descends to the lower platform of the furnace repairing trolley through the ladder on the upper platform of the furnace repairing trolley; Furnace building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com