Full automatic labeling machine

A labeling machine, fully automatic technology, applied in the directions of labeling machines, labels, lamination auxiliary operations, etc., can solve the problems of unfavorable standardization, industrialization, automation, large human factors affecting labeling quality, and high labor costs, and achieve The effect of reducing production labor costs, improving labeling quality, and stable equipment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

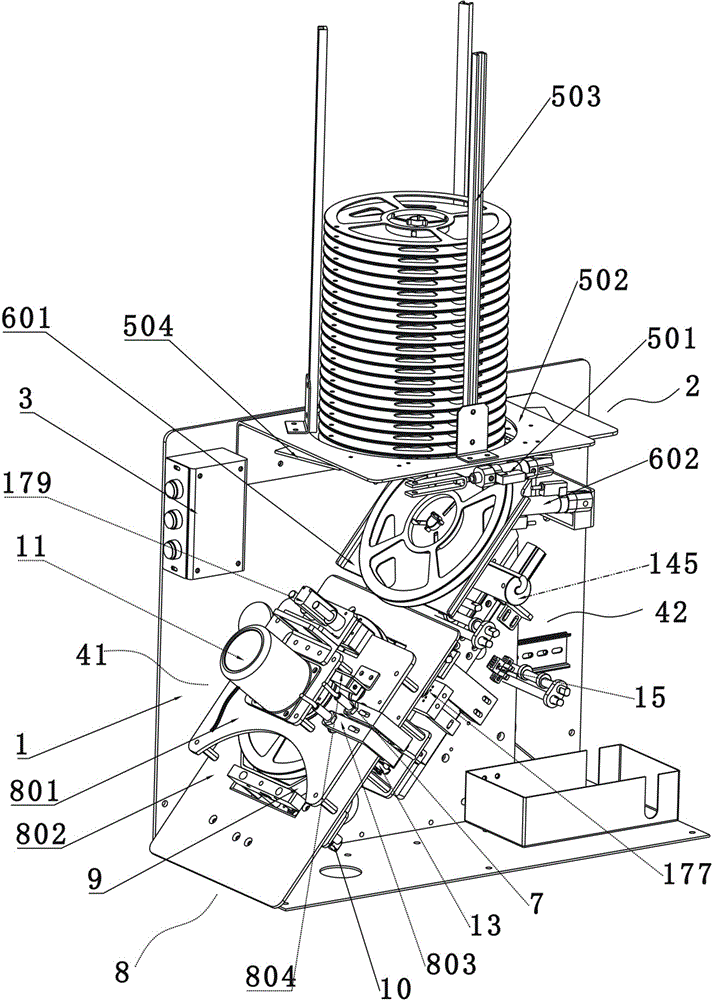

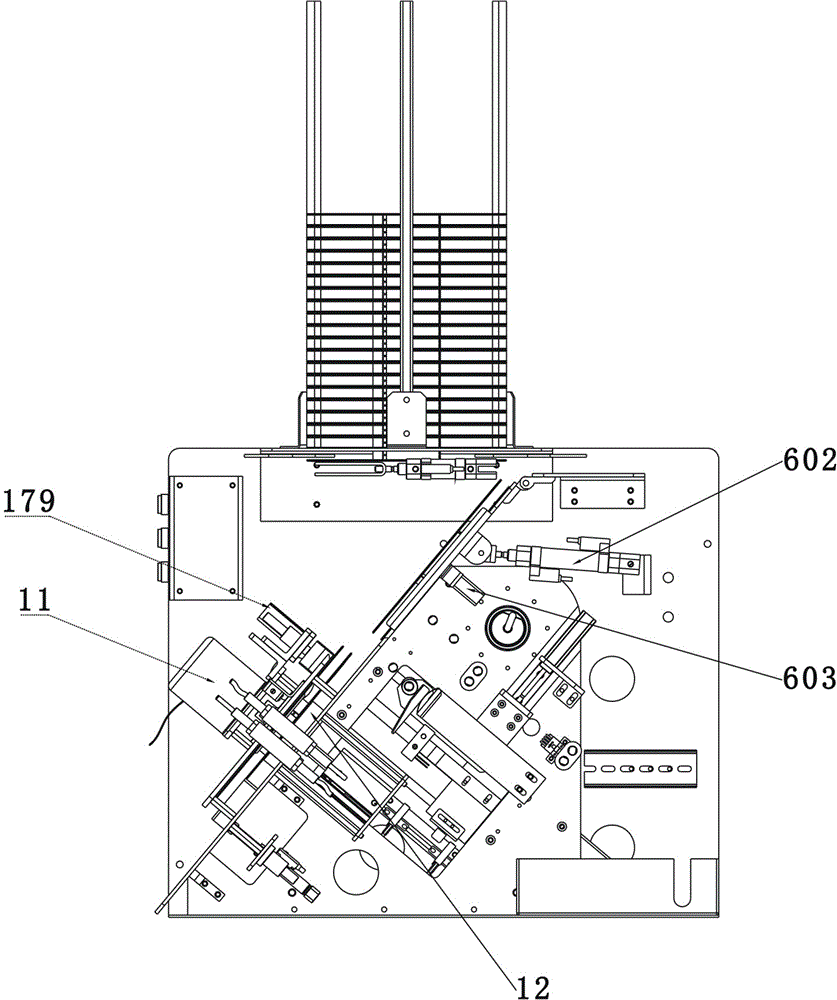

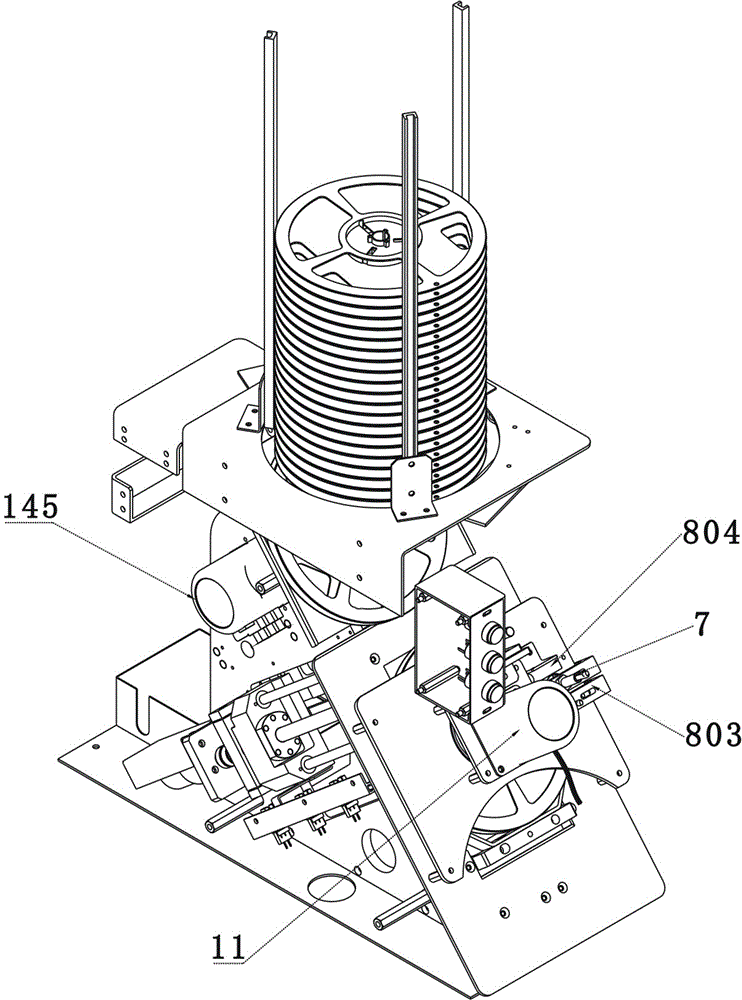

[0020] Below in conjunction with specific embodiment and accompanying drawing ( Figures 1 to 4 ), further elaborating the essence of the present invention.

[0021] A fully automatic labeling machine involved in the present invention includes a frame 1, a feeding mechanism 2, a labeling mechanism, and an electric control system 3. The discharging mechanism 2 is fixedly connected to the frame 1, and the discharging mechanism 2 includes an automatic disk-putting device and an auxiliary disk-taking device, the automatic disk-putting device is fixedly arranged on the frame 1, the auxiliary disk-taking device includes a support plate 601, a material-supporting driver 602, and the material-supporting driver 602 is fixedly installed on the machine frame On the frame 1 , the supporting driver 602 is movably connected with the support plate 601 , and the locator 603 is installed on the support plate 601 , and the locator 603 is movably connected with the support plate 601 . The label...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com