Micro-nano high-efficiency painting mist purifying tower

A paint mist purification, micro-nano technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as increased wind resistance of exhaust fans, fine paint mist particles, and treatment equipment failure, and achieve stable equipment performance. , The effect of low processing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

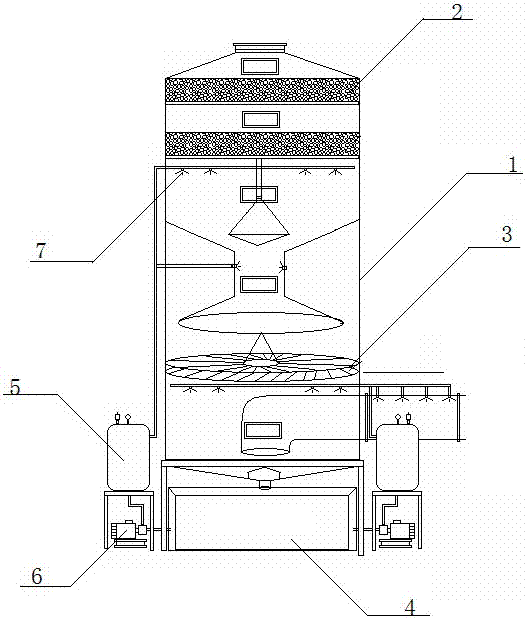

[0015] The present invention is described below by embodiment, as figure 1 As shown, the present invention provides a micro-nano high-efficiency paint mist purification tower, its structure includes: Pall ring packing layer 2, swirl plate 3, purification tank water tank 4 and water circulation system 5; wherein Pall ring packing 2 There are two layers, which are distributed in parallel on the top of the paint mist washing tower 1, and a swirl plate 3 is arranged in the middle of the paint mist washing tower 1, and an hourglass-shaped one is arranged in the middle of the swirl plate 3 and the Pall ring packing layer 2. The channel forms a secondary impact spray chamber; a purification tank water tank 4 is arranged at the bottom of the paint mist washing tower 1, and a funnel-shaped collecting plate is arranged above the purification tank water tank 4, and the upper part of the center of the collecting plate is the air intake of the air intake pipe. The inlet pipe is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com