Fully-automatic efficient mulch applicator

A fully automatic, laminating machine technology, applied in the field of machinery, can solve the problems of waste of resources, waste of materials, slow response, etc., to achieve the effects of stable equipment performance, high lamination efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

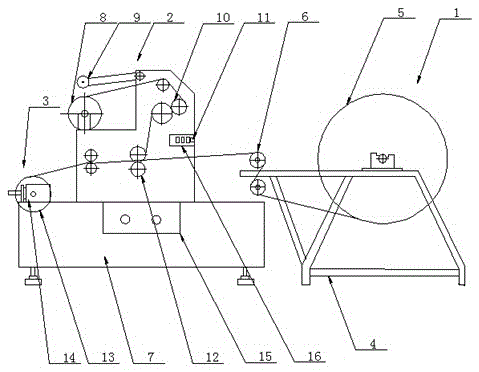

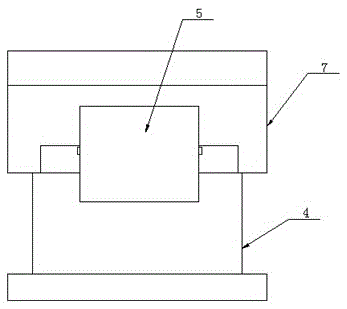

[0016] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

[0017] see as figure 1 —— figure 2 As shown, the specific embodiment adopts the following technical scheme: it includes a paper feeding mechanism 1, a film covering mechanism 2, a winding mechanism 3, a frame 7, and a controller 15; the winding mechanism 3 includes a winding roller 13 and Winding motor 14, the output shaft of winding motor 14 is connected with winding roller 13; One side of described paper feeding mechanism 1 is provided with laminating mechanism 2, and one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com