Laser direct writing device based on combined vortex double focusing light spot

A compound vortex and focusing spot technology, which is applied in the direction of photolithography exposure equipment, microlithography exposure equipment, etc., can solve the problems of reduced working wavelength and difficulty in aberration correction, so as to reduce stringent requirements and achieve lateral resolution , the effect of high horizontal resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

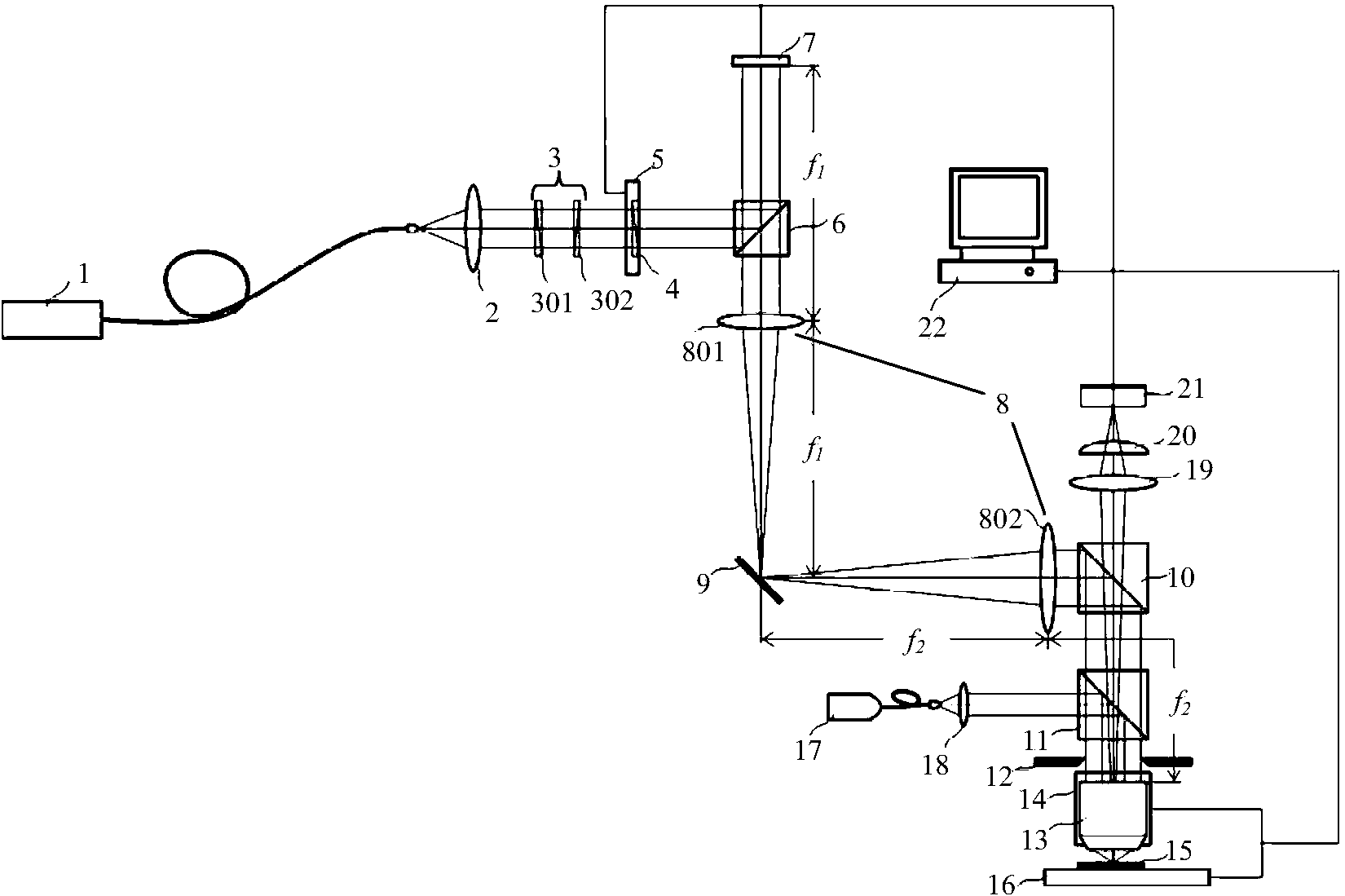

[0036] Taking a focusing lens with NA=0.6 as an example, a specific implementation scheme of a double-lobe focusing spot laser direct writing system realized by a compound vortex is proposed below.

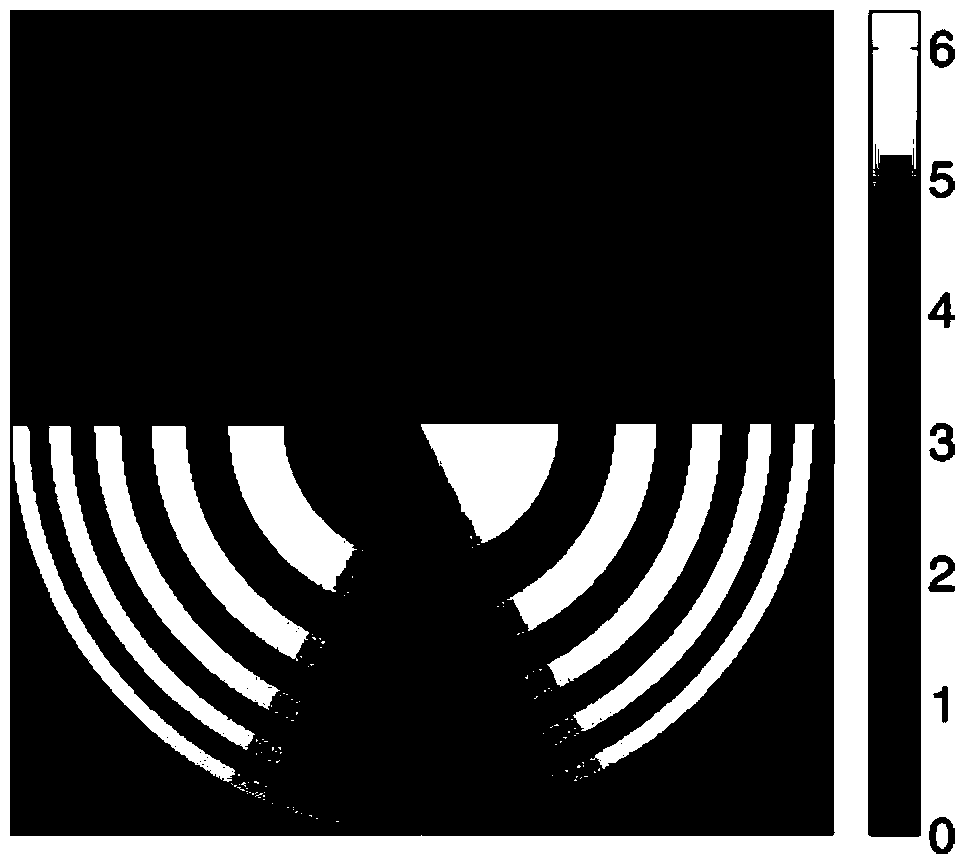

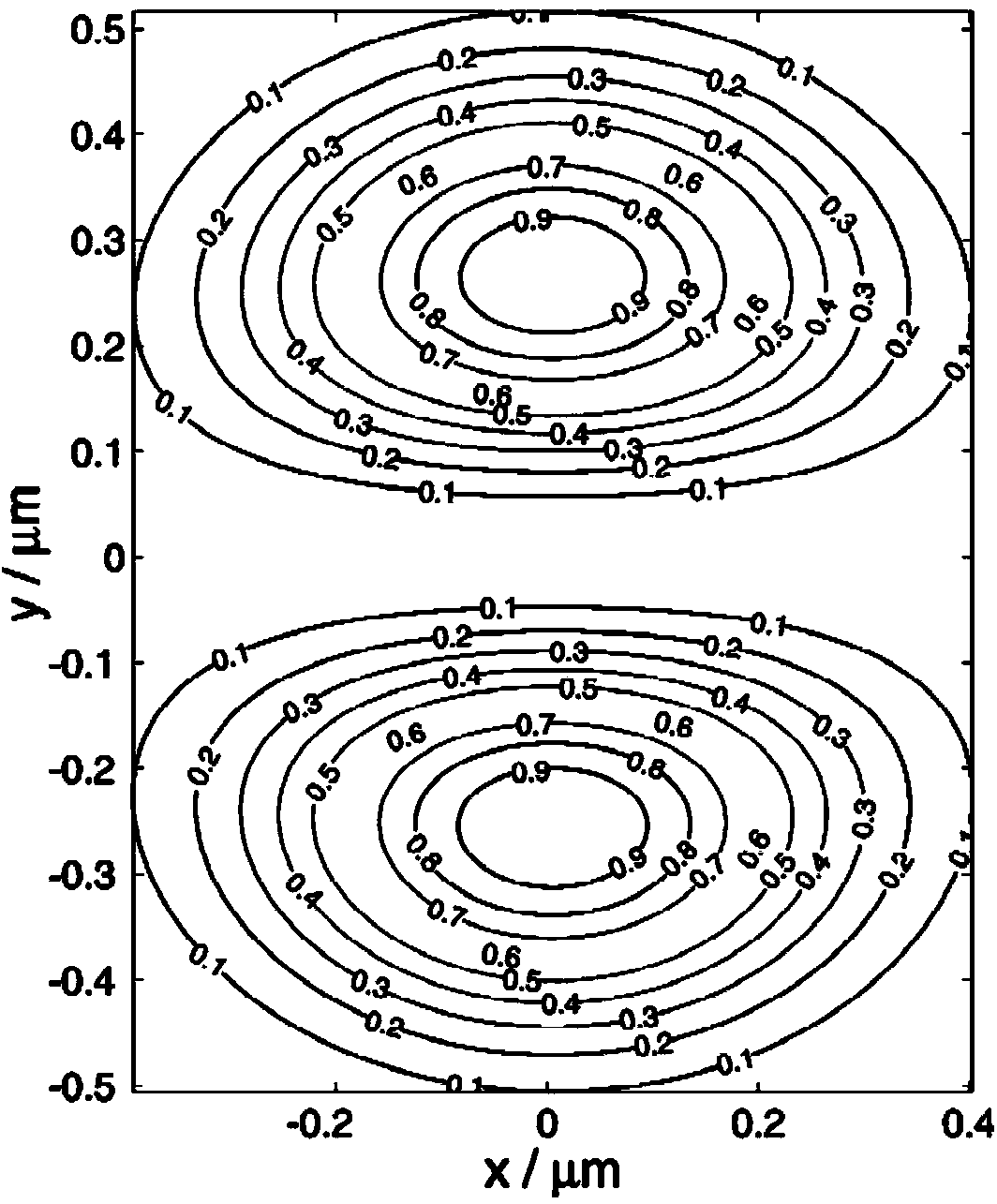

[0037] Here we choose NA=0.6, the incident aperture of the focusing lens is 6mm, and the aperture stop aperture on the rear focal plane of the objective lens is 6mm. The spatial light modulator is a Holoeye Pluto VIS (single pixel 8 μm, total pixel number is 1920×1080) working in pure phase modulation mode. The self-focusing servo drive 14 can be an axial piezoelectric ceramic nano drive with a linear range of 2 microns and a closed-loop resolution of 0.2 nm. The total number of compound vortex phase equal-area regions in formula (1) is selected as N=10. When the initial phase difference between adjacent ring areas is π, the phase distribution in the incident aperture of the focusing objective lens is as follows: figure 1 shown. The focal lengths of the first lens (801) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com