Alternating current induction motor detection brake device and detection system

A technology of induction motors and braking devices, which is applied in the direction of motor generator testing, etc., can solve problems such as shaft surface damage and complex structures, and achieve the effects of shortening detection time, improving detection efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

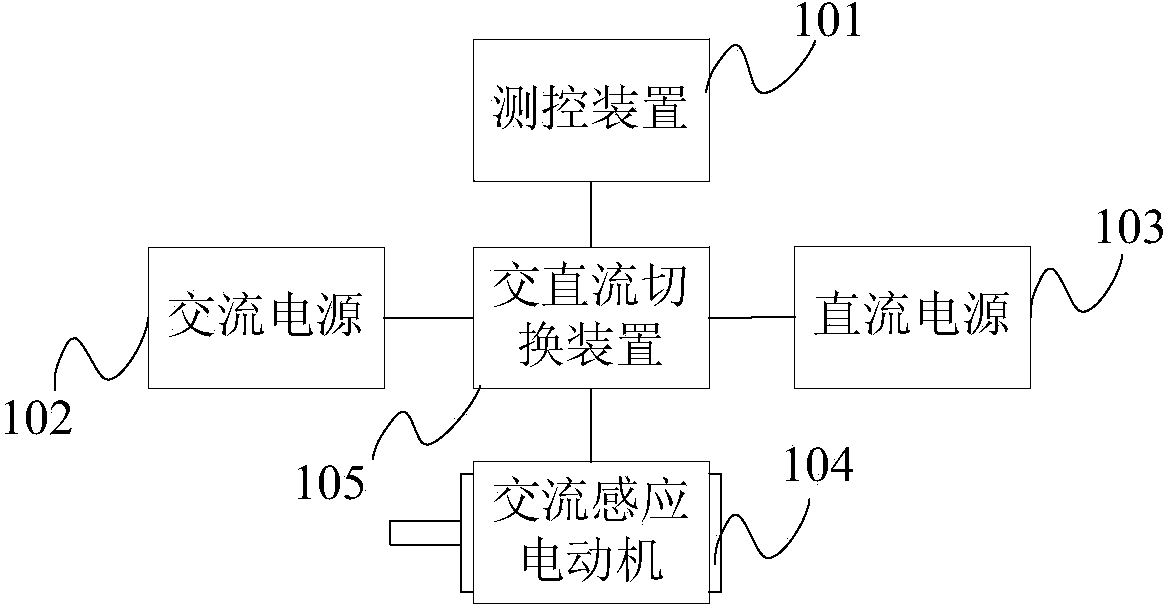

[0051] Such as figure 1 As shown, it is a schematic structural diagram of a detection and braking device for an AC induction motor of the present invention, which is applied to a detection system for an AC induction motor. The system may include a measurement and control device 101 and an AC power supply 102, and the detection and braking device may include:

[0052] A DC power supply 103 connected to the measurement and control device 101 .

[0053] Wherein, the DC power supply 103 can specifically be a program-controlled DC power supply. At this time, the program-controlled DC power supply can be connected to the measurement and control device 101; of course, the DC power supply 103 can also be an ordinary DC power supply, such as a DC stabilized power supply. This is not specifically limited.

[0054] The AC-DC switching device 105 connected to the measurement and control device 101, the AC power supply 102, the DC power supply 103, and the AC induction motor 104 respectiv...

Embodiment 2

[0060] For the detection of single-phase AC induction motors, the present invention provides another detection and braking device for AC induction motors, such as figure 2 The schematic diagram of the detection and braking device shown is applied to the detection system of an AC induction motor. The system may include: a measurement and control device 201 and a single-phase programmable AC power supply 202 connected thereto, and the detection and braking device may include:

[0061] A program-controlled DC power supply 203 connected to the measurement and control device 201 .

[0062] The AC-DC switching device 205 connected to the measurement and control device 201, the program-controlled DC power supply 203 and the single-phase AC induction motor 204 respectively. In the embodiment of the present invention, the AC-DC switching device 205 may include: a first relay J1 and a second relay J2, in,

[0063] The normally closed contact of the first relay J1 is connected with the...

Embodiment 3

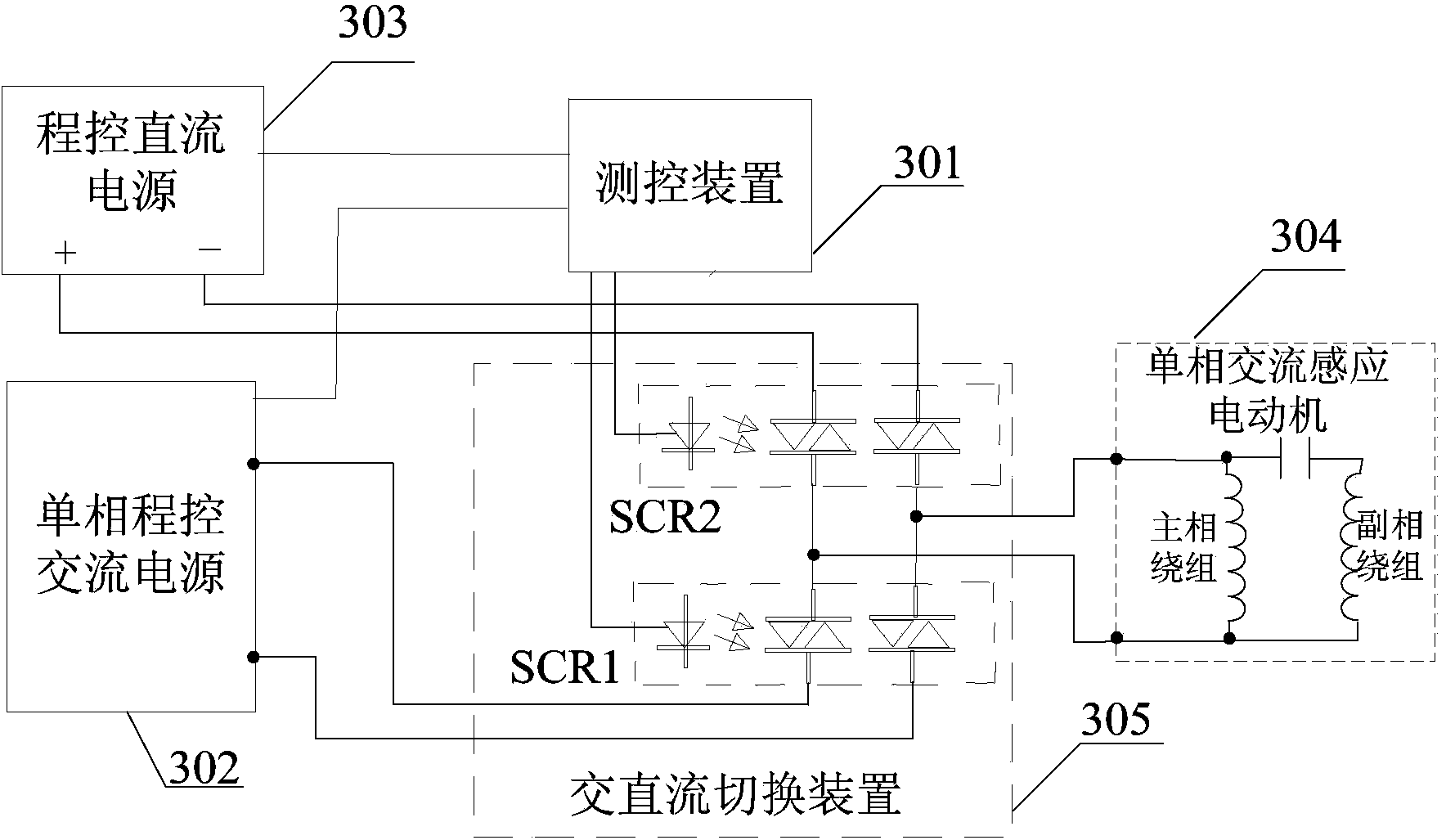

[0071] For the detection of single-phase AC induction motors, the present invention provides another detection and braking device for AC induction motors, such as image 3The schematic structural diagram of the detection and braking device shown is applied to the detection system of an AC induction motor. The system may include: a measurement and control device 301 and a single-phase programmable AC power supply 302 connected thereto, and the detection and braking device may include:

[0072] A program-controlled DC power supply 303 connected to the measurement and control device 301 .

[0073] The AC-DC switching device 305 connected to the measurement and control device 301, the program-controlled DC power supply 303 and the single-phase AC induction motor 304 respectively. In the embodiment of the present invention, the AC-DC switching device 305 may include: the first photo-controlled thyristor component SCR1 and The second photo-controlled thyristor component SCR2, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com