Heat dissipation structure of condenser and refrigerator with such structure

A heat dissipation structure and condenser technology, applied in coolers, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of slow heat dissipation of the heat dissipation system, increased power consumption, and long working hours of refrigerators, so as to reduce the cost of refrigerators, The effect of improving cooling efficiency, reducing boot rate and running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

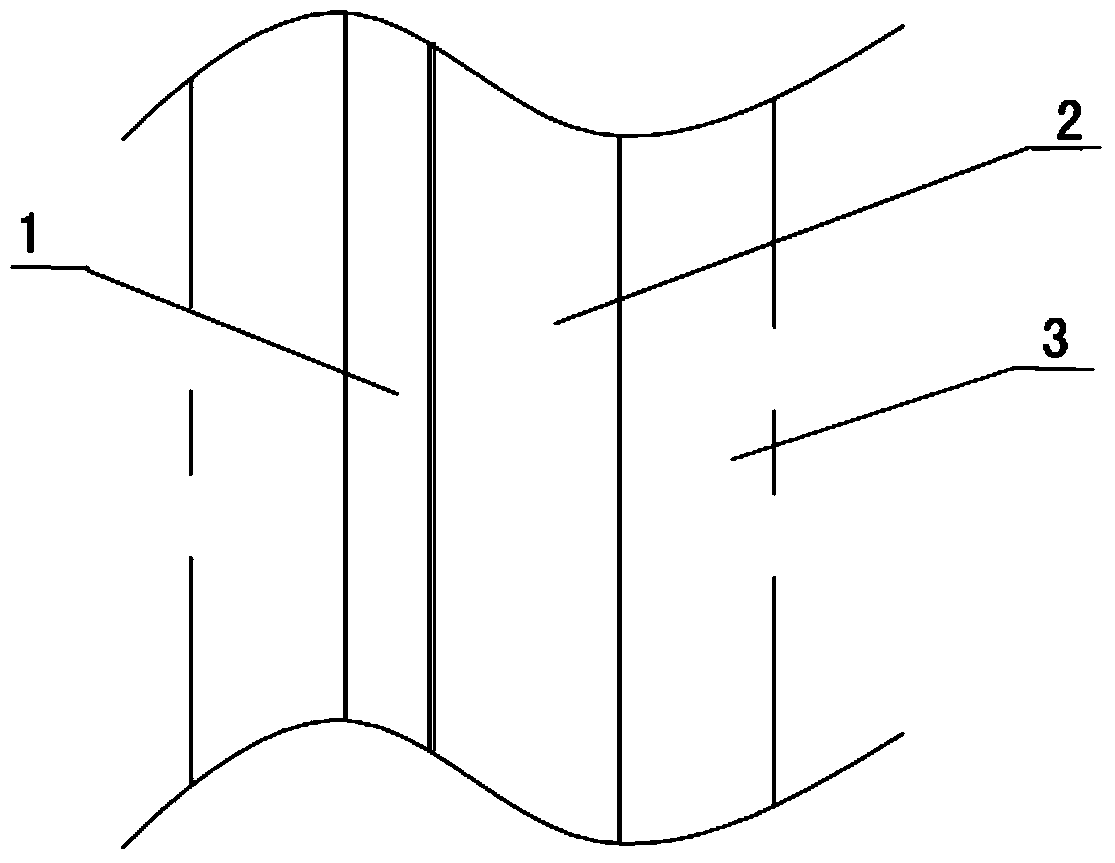

[0018] In this embodiment, a heat dissipation structure of a condenser and a refrigerator thereof are applied in such as figure 1 In the refrigeration system shown, the components of the refrigeration system include: compressor unit, condenser, filter, capillary tube and evaporator, such as figure 2 and image 3 As shown, on one side of the condenser 1, a water-cooled heat accumulator 2 is attached in parallel along the arrangement direction of the condenser 1. The water-cooled heat accumulator 2 is closely attached to the condenser 1 and is attached to the refrigerator shell through the aluminum foil tape 3. They are fixed together to form a heat dissipation structure for the condenser 1, so that the water-cooled heat accumulator 2 exchanges heat with the condenser 1 when the refrigerator is in operation. On the one hand, the aluminum foil tape 3 plays a fixing role, and on the other hand, it also makes the heat exchange between the water-cooled heat accumulator 2 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com