Carboxylesterase as well as coding gene and application thereof

A carboxylesterase and gene technology, applied in the field of genetic engineering, can solve problems such as difficult mass production, limited enzyme production capacity of wild strains, long fermentation cycle, etc., achieve good activity and stability, easy to obtain pure protein, and short cultivation cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Cloning of CareW of carboxylesterase gene

[0042] The genomic DNA of Bacillus K91 was extracted with the Genome Extraction Kit (DP302) of Bacillus sp.

[0043] According to Bacillus K91 whole genome sequencing and gene annotation, analyze the carboxylesterase gene CareEW and design expression primers CareEW F and CareEW R:

[0044] Upstream primer CareW F: 5’-ACTCATCAAATAGTAACGAC-3’

[0045] Downstream primer CareW R: 5’-TTCTCCTTTT GAAGGGAATA G-3’

[0046] Upstream primer T7: 5’-TAATACGACTCACTATAGGG-3’

[0047] Downstream primer T7ter: 5’-TGCTAGTTATTGCTCAGCGG-3’

[0048] T7 and T7ter are primers for PCR detection of positive clones.

[0049] PCR amplification was carried out with the genomic DNA of Bacillus thermophilus K91 as a template. The PCR reaction parameters were: 94°C pre-denaturation for 1min30sec; then 94°C denaturation for 30sec; 58°C annealing (0.5°C per cycle) 30sec; 72°C extension for 1min40sec; After 28 cycles, denaturation at 94°C for 30sec; annealing a...

Embodiment 2

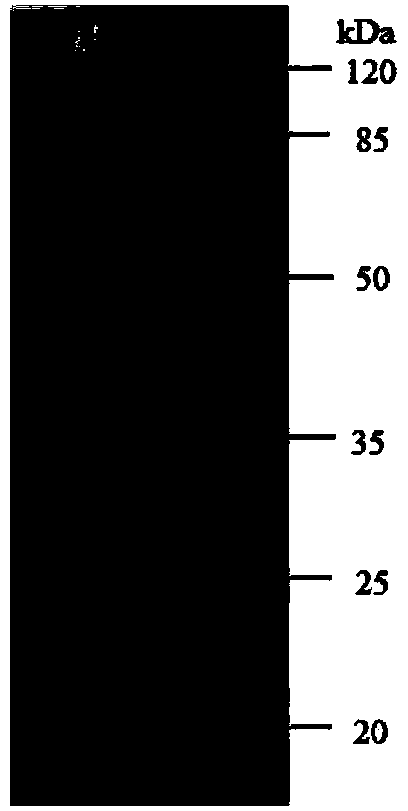

[0051] Example 2: Preparation of Recombinant Carboxyesterase CareEW

[0052] Take the recombinant plasmid pEASY TM -E2-CarEW's BL21(DE3) strain and only contains pEASY TM -E2 empty plasmid BL21(DE3) strain, inoculated in LB (containing 100ug / mL Amp r ) In the culture solution, shake rapidly at 37°C for 16 hours. Then the activated bacterial solution was inoculated into fresh LB (containing 100ug / mL Amp r ) In the culture medium, fast shaking culture for about 2–3h (OD 600 After reaching 0.4-0.7), IPTG with a final concentration of 0.7mM was added for induction, and shaking culture was continued for about 20h at 20°C. Centrifuge at 12000 rpm for 10 min to collect the bacteria. Use appropriate amount of pH7.0 citric acid-Na 2 HPO 4 After suspending the bacteria in the buffer, the bacteria are broken by ultrasonic in a low temperature water bath. After centrifugation of the above concentrated crude enzyme solution at 12,000 rpm for 10 minutes, the supernatant was aspirated and the ...

Embodiment 3

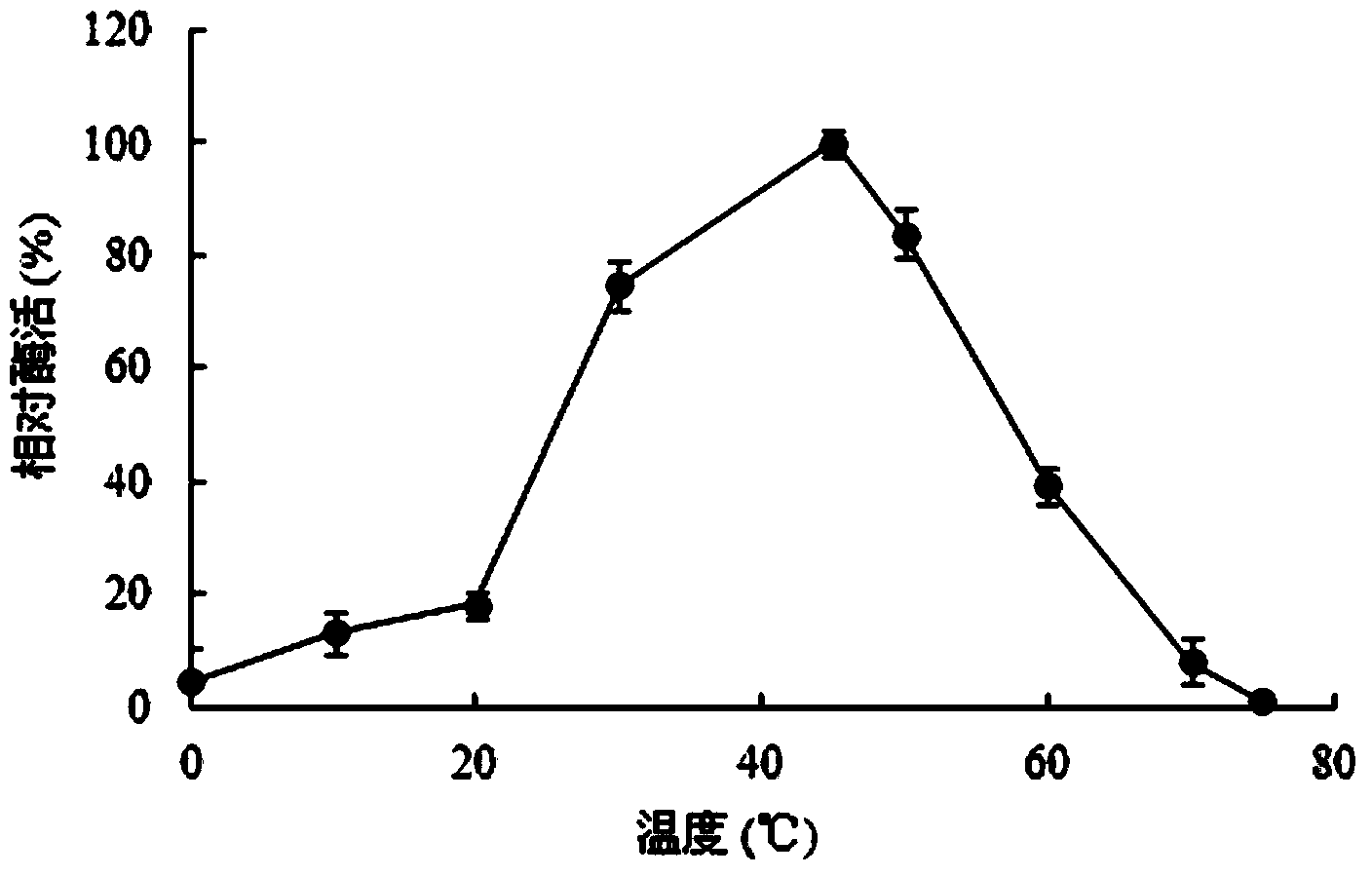

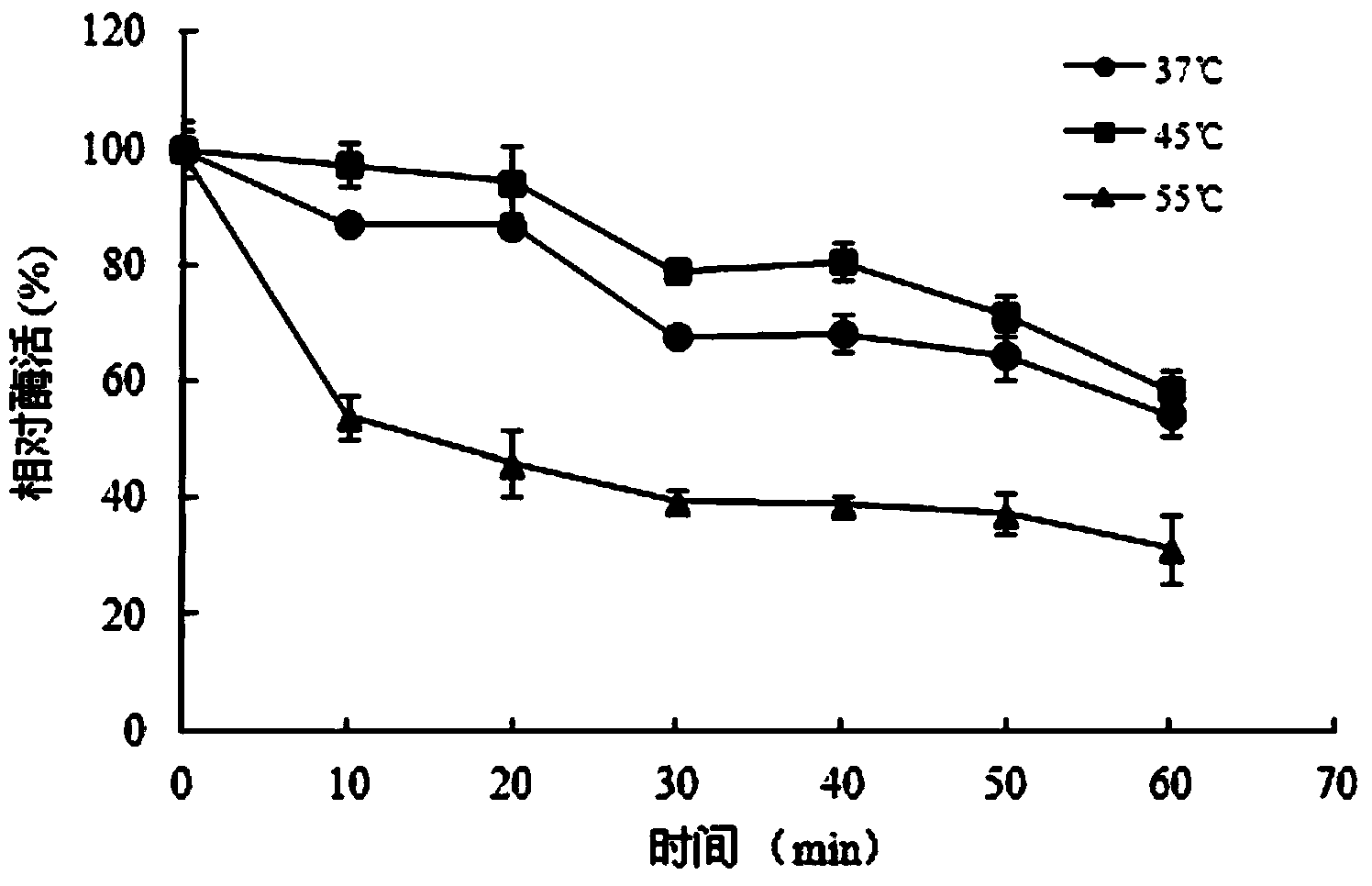

[0053] Example 3: Determination of the properties of purified recombinant carboxylesterase CarEW

[0054] 1. Activity analysis of the recombinant carboxylesterase CarEW

[0055] The purified recombinant esterase CarEW uses p-nitrophenol method for activity determination: Take 4 1.5mL centrifuge tubes, numbered 1, 2, 3, 4, of which 1, 2, 3 test tubes are the experimental group (3 replicates), No. 4 is the control group. Add 420 μL of 50 mM citric acid-Na pH 7.5 to the four centrifuge tubes. 2 HPO 4 Buffer, 0.4% Trion-100, 0.1% gum arabic emulsion and 30μL 10mM substrate pNPC 4 After preheating at 37°C for 5 minutes, add 50μL of enzyme solution diluted by an appropriate multiple to tubes 1, 2 and 3 every 10s, add the same amount of water to the control tube No. 4, react at 37°C for 5 minutes and then turn to 1 every 10s. 2, 3 Add 50μL of 0.1M Na to the experimental tube 2 CO 3 To stop the reaction, add an equal volume of stop solution to the No. 4 control tube and immediately insert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com