Negative thermal expansion material HfMnMo2PO12 and preparation method thereof

A negative thermal expansion material, hfmnmo2po12 technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of few negative thermal expansion materials, and achieve the effect of large negative thermal expansion coefficient, wide source and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The negative thermal expansion material HfMnMo prepared in this embodiment 2 PO 12 , by HfO 2 , Mn 2 o 3 、MoO 3 , NH 4 h 2 PO 4 It is made by hot pressing and sintering, which specifically includes the following steps:

[0029] (1) In terms of molar ratio, the raw materials are divided into HfO 2 :Mn 2 o 3 :MoO 3 : NH 4 h 2 PO 4 =2:1:4:2, weighed, mixed evenly, and ground for 2 hours; in order to mix the raw materials evenly, add an appropriate amount of absolute ethanol during the mixing or grinding of the raw materials;

[0030] (2) After the raw materials in step (1) are dried, they are pressed into tablets to make embryos;

[0031] Dry at 80°C for half an hour;

[0032] Tablet pressing is to use a single-axis dry powder tablet press to make the powder into a cylindrical green body with a diameter of 10 mm and a height of about 5 mm under a pressure of 200 MPa;

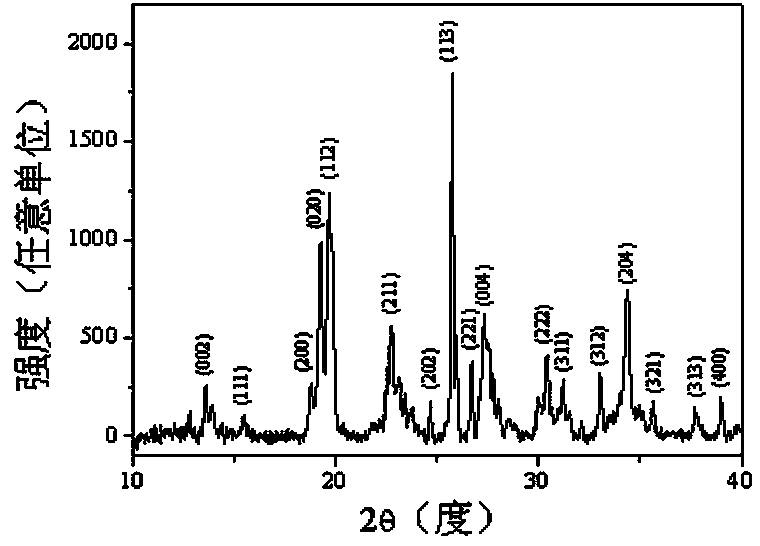

[0033] (3) Place the embryo body in step (2) in a box-type furnace at a heating rate of ...

Embodiment 2

[0036] The preparation of this example is the same as that of Example 1, only the sintering temperature is adjusted to 800° C., and the holding time is 8 hours.

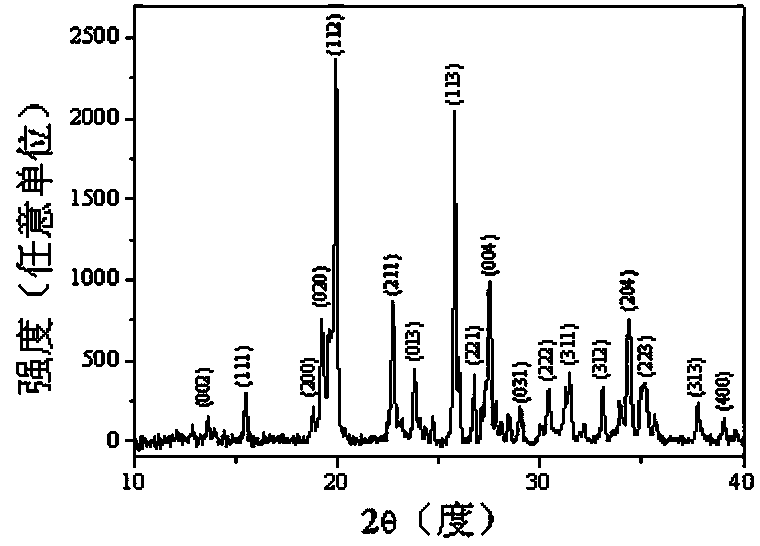

[0037] The negative thermal expansion material HfMnMo prepared in this embodiment 2 PO 12 Corresponding XRD pattern phase analysis see figure 2 , the analysis shows that the product phase is mainly an orthogonal structure, and its main diffraction peak is consistent with the PDF card number 00-051-0581, indicating that the prepared sample is a pure phase substance.

Embodiment 3

[0039] The preparation of this example is the same as that of Example 1, only the sintering temperature is adjusted to 900° C., and the holding time is 6 hours.

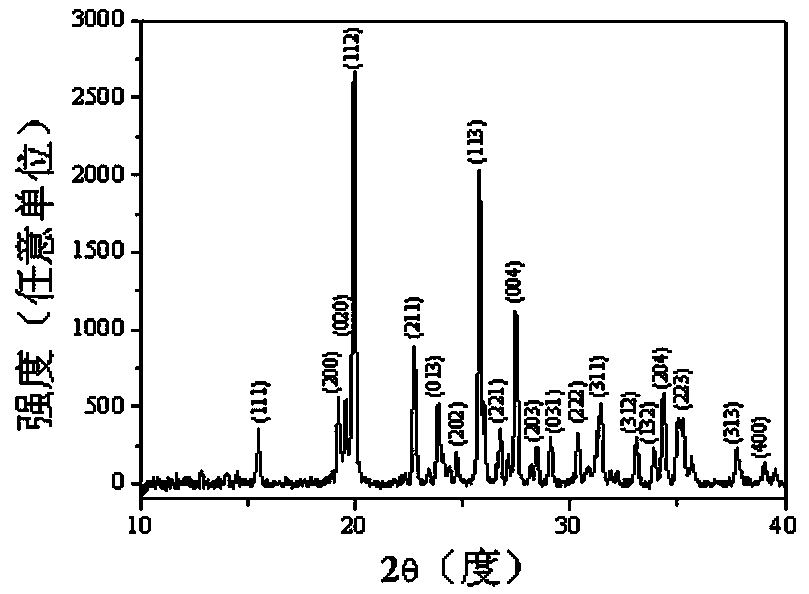

[0040] The negative thermal expansion material HfMnMo prepared in this embodiment 2 PO 12 Corresponding XRD pattern phase analysis see image 3 , the analysis shows that the product phase is mainly an orthogonal structure, and its main diffraction peak is consistent with the PDF card number 00-051-0581, indicating that the prepared sample is a pure phase substance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com