Connected finished product die-cutting anti-adhesion and all-waste cleaning integrated system of die-cutting machine

An integrated system and die-cutting machine technology, applied in the field of integrated systems, can solve the problems of high labor cost, time-consuming and laborious, and achieve the effect of realizing automation, solving manual waste removal, and overcoming manual adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

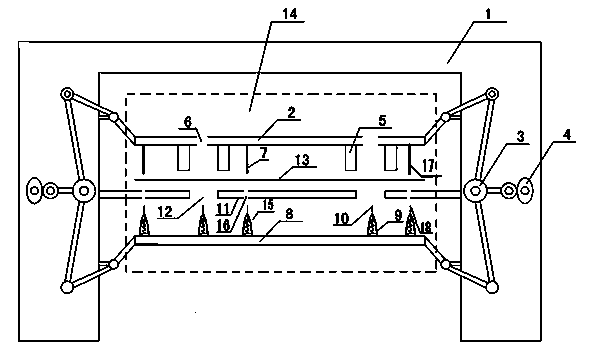

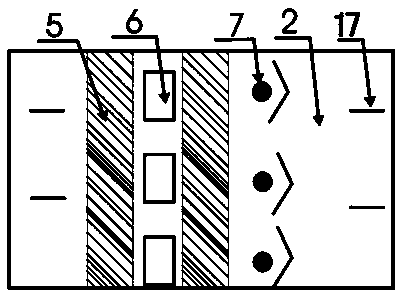

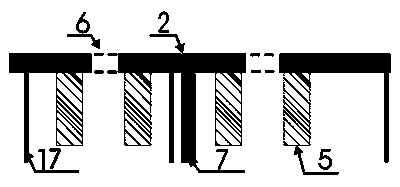

[0012] like figure 1 , figure 2 , image 3 , Figure 4 As shown, both sides of the frame 1 are equipped with cams 4 symmetrically, and the cams 4 are symmetrically connected to the connecting rods 3 respectively, and the wooden upper stripping board 2 and the lower frame 8 of the stripping part 14 are respectively fixed on the connecting rods 3; Sponge strips 5 are glued on the board 2, and vent holes 6 are arranged between the two sponge strips 5. On the corresponding place inside the printing of the paper 13, on the top cleaning waste board 2, there are upper cleaning waste needles 17, and the paper 13 has two side gauges. Corresponding place at the edge, the upper cleaning waste plate 2 has the upper cleaning needle two 17; the lower frame 8 is equipped with the lower thimble mounting seat 9, and the lower thimble one 10, the lower thimble two 15, and the lower thimble three 18 are installed on the lower thimble In the installation seat 9; the wooden middle stripping bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com