Multilayered film and method for manufacturing same

A multi-layer film and coating technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of long-term stability of photovoltaic cells, poor adhesion strength of fluoropolymers, complex manufacturing methods, etc. Achieve excellent durability, ensure adhesive strength, and achieve excellent adhesive strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

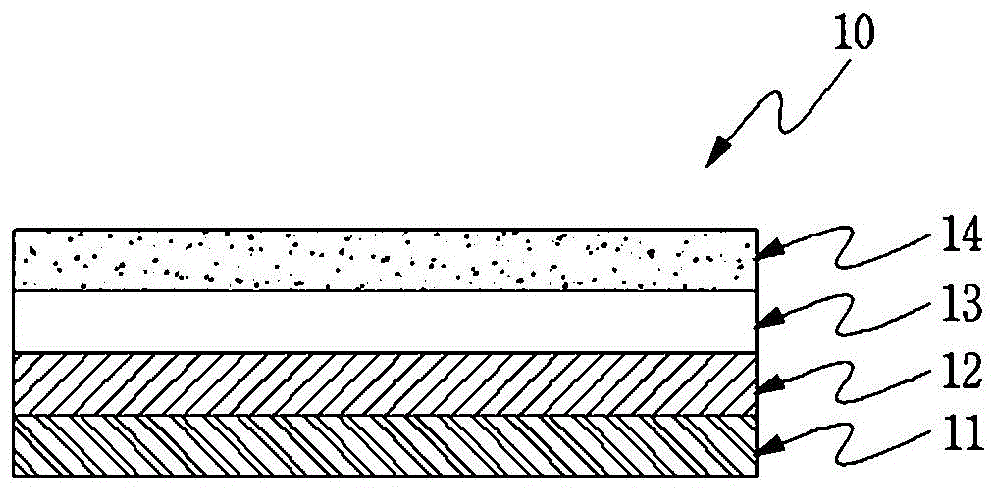

[0101] According to the present application, the above method is used first to form the primer layer, and then the coating method is used to form the fluoropolymer coating. In the present application, the coating solution for forming the fluoropolymer coating can be obtained by dissolving or dispersing the various components forming the above-mentioned fluoropolymer coating in a solvent having a relatively low boiling point (especially a solvent having a boiling point of 200° C. or lower). ) to prepare. According to an exemplary embodiment of the present application, when the fluoropolymer has an amorphous region or is mixed with an amorphous resin, the components forming the fluoropolymer coating can be effectively dissolved in a solvent having a relatively low boiling point. Therefore, in this application, since a high-temperature drying step is not required in the manufacturing process, the manufacturing cost can be saved, and the quality of the product can also be improved...

preparation Embodiment 1 to 6

[0130] Preparation Examples 1 to 6: Preparation of Primer

[0131] 300 g of toluene was put into the reactor, and the temperature in the reactor was kept at 80°C. In this case, the inside of the reactor was filled with nitrogen gas to suppress oxidation reaction due to external air, and the reaction product was continuously stirred in a stirrer to promote the reaction. The temperature condition was set at 80°C, and various acrylic monomers prepared as listed in Table 1 below were charged into the reactor. After the addition of the acrylic monomer is complete, add the silane coupling agent KBM503. In this case, the mixing ratio and addition amount of the acrylic monomer and the silane coupling agent prepared in each preparation example are listed in Table 1.

[0132] Next, 1 g of 2,2-azobis(2,4-dimethylvaleronitrile) (V-65) as an initiator was dissolved in 20 g of toluene, and added to the reaction with a syringe for radical copolymerization. The resulting mixture was stirre...

Embodiment 1 to 12

[0136] Preparation of Substrate Layers

[0137] The surface of a PET film (thickness: 250 μm, available from Kolon corp) whose surface was treated with an acrylic primer was subjected to corona treatment.

[0138] The surface of the PET film was coated with an adhesive, dried at 100° C. for 1 minute, and then adhered to an aluminum foil (Al foil) having a thickness of 20 μm using a laminator. The rolls of the laminator were kept at a temperature of 60°C when the PET film was adhered to the Al foil. Afterwards, sufficient curing time is used to cure the adhesive in an aging step in which the adhesive is left to stand at room temperature for 1 day, and then left to stand in an oven at a temperature of 40 to 60° C. for 4 days. The solid content of the adhesive is adjusted so that the thickness of the adhesive after drying is about 10 to 13 μm.

[0139] Preparation of Coating Solution for Fluoropolymer Coating

[0140] Preparation of White Fluoropolymer Coating Solution

[014...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com