Lightening current drainage stripe and manufacturing method thereof

A technology of drainage strip and lightning, applied in the field of lightning drainage strip and its production, can solve the problems of many exposed parts of metal sheets, troublesome arrangement of metal sheets, low processing efficiency, etc., so as to reduce the difficulty of processing and operation, and improve the processing efficiency. And the degree of neatness, the effect of improving product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

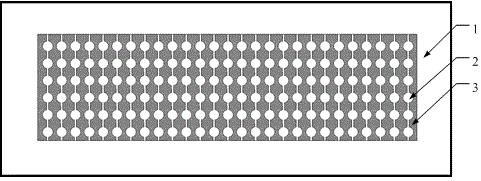

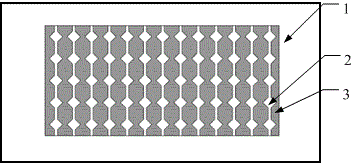

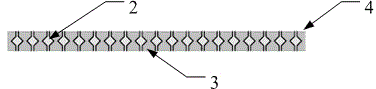

[0037] see image 3 , 4 , 5, a lightning drainage strip, including a drainage strip body 8, a plurality of groups of metal sheets 2 are distributed on the strip 4 of the drainage strip body 8, and insulating medium 3 is filled around the metal sheet 2, and the insulating medium 3 can be made of aluminum Powdered adhesive, the insulating base tape 6 is provided with a double-sided tape 7. The metal thin plate 1 is an aluminum plate or a stainless steel plate with a thickness of 0.1-0.5mm, and the length and width are determined according to actual needs. Figure 4 and Figure 5 An example of a lightning current strip made as described below. see figure 1 , figure 2 , on the thin metal plate 1, the shape of the transverse connection of the metal sheets 2 is cut out by laser cutting or other means. figure 1 The metal sheet is round in sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com