Assembly joints and construction methods of double-ear plate square pipe column and h-shaped steel frame with variable beam height

A double lug plate and steel beam technology, which is applied in the direction of construction and building construction, can solve the problems of difficult standardization and poor universal type, and achieve the effects of improving versatility and construction efficiency, good rotational stiffness, and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

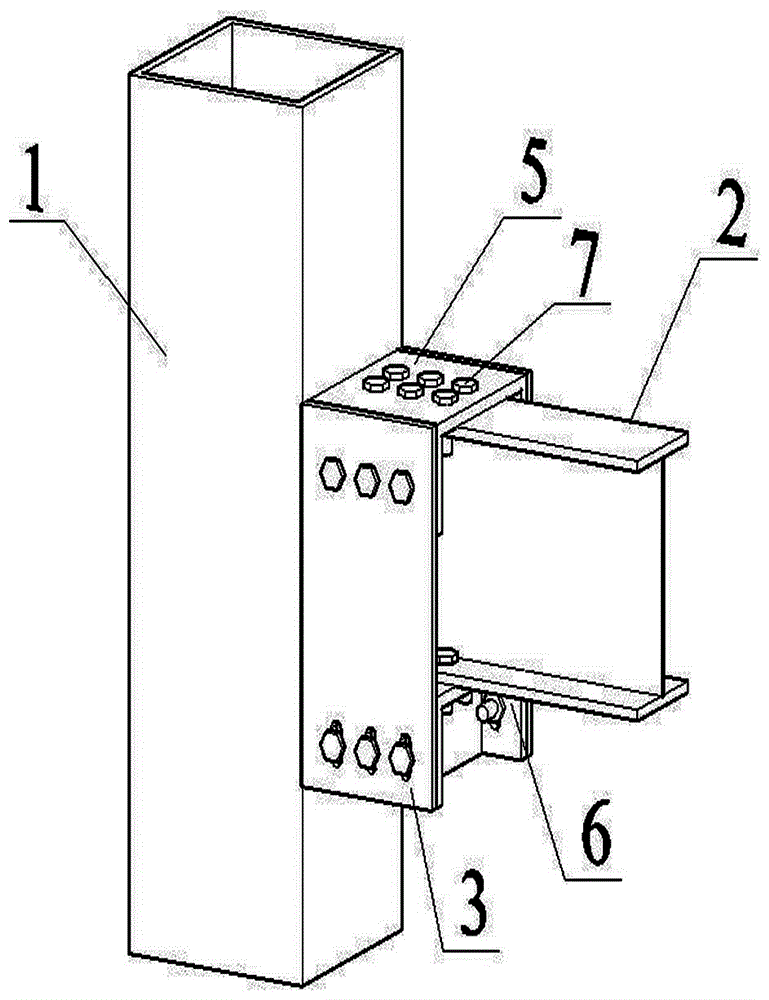

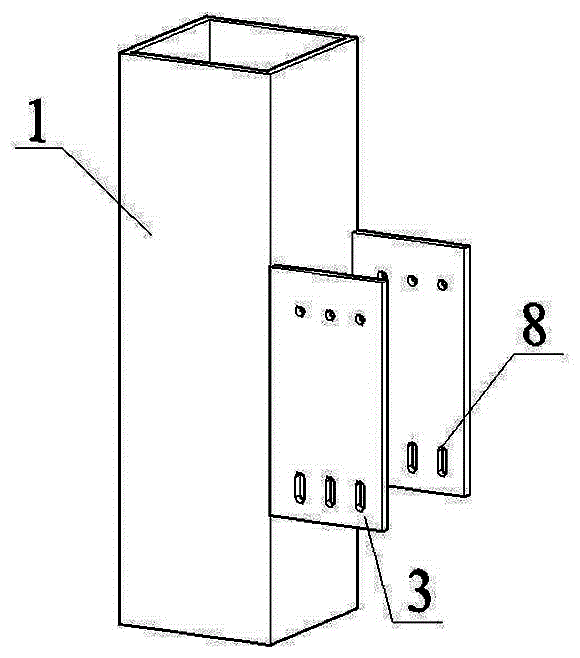

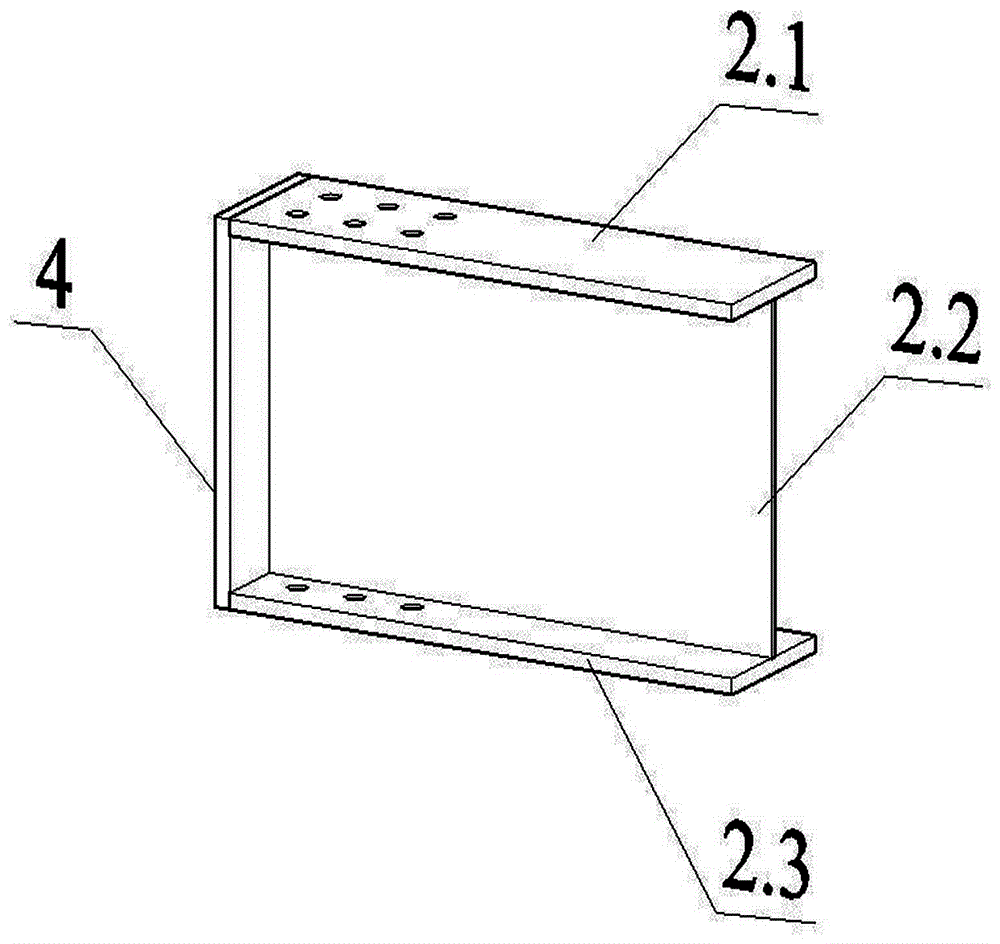

[0039] Examples see Image 6 and Figure 7 As shown, a double ear plate type square steel pipe column and H-shaped steel beam variable beam height assembled joint, including square steel pipe column in the node area, H-shaped steel beam in the node area and connectors, the connectors include ear plates, end plate and independently set upper and lower connectors. It is characterized in that: the ear plate is welded to the square steel pipe column, and the end plate is welded to the H-shaped steel beam; the upper and lower flanges of the H-shaped steel beam are connected with the ear plate on the side of the column through the upper and lower connectors and high-strength bolts, and the beam section The bending moment and shear force are transmitted to the ear plate to realize the reasonable stress of the structure.

[0040] The assembled joint between the double ear plate square steel pipe column and the H-shaped steel beam variable beam height is characterized in that the ear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com