Preparation method for composite spice derived from bolete and application of composite spice for enhancing fragrance for tobaccos

A technology of boletus and boletus, which is applied in the field of tobacco spices, can solve the problems of bad taste of new cigarette products, and achieve the effects of easy industrial production, mild reaction conditions and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

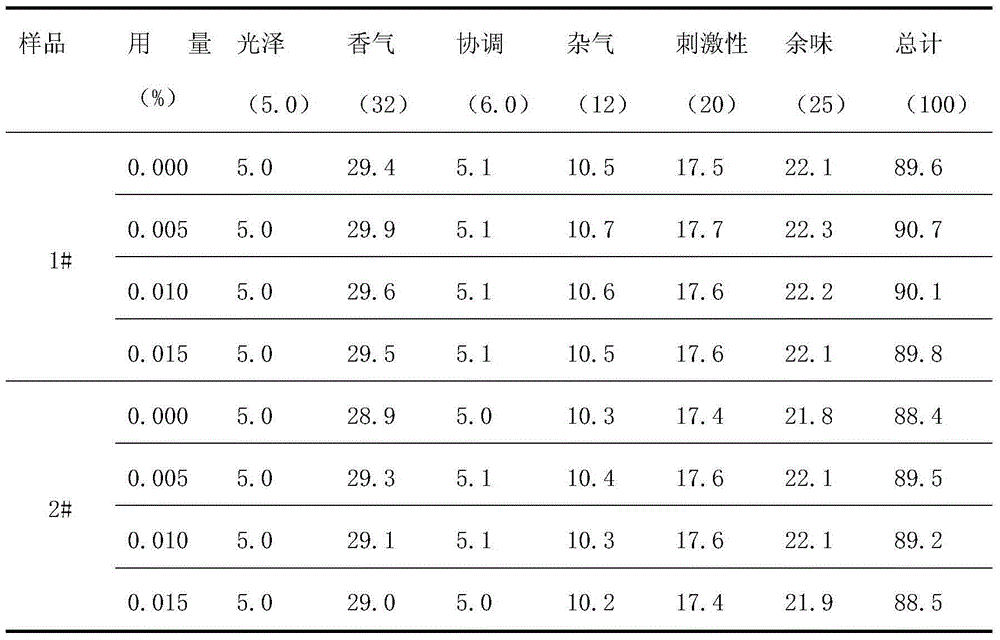

[0023] White boletus (Boletus edulis) fruit body is crushed, dried at low temperature, water: white boletus dry powder = 3:1 (weight ratio, abbreviated as w / w, the same below), and the ultrasonic extraction time is maintained at 60°C. 3h; the obtained extract was concentrated and dried to obtain the white boletus extract, weighed the extract and arabinose respectively, reacted at 100°C for 2h according to the ratio of 5:1, filtered and concentrated into a paste, and added to cigarettes in different proportions Spray the spice liquid on the shredded tobacco, and evaluate its application effect in cigarettes. The evaluation results are shown in Table 2.

[0024] Table 2 The application effect of flavoring materials on the sensory quality of cigarettes

[0025]

[0026] The results show that adding an appropriate amount of the compound spices to the cigarette samples can endow them with a special aroma, significantly increase the aroma of the cigarette, and at the same time im...

Embodiment 2

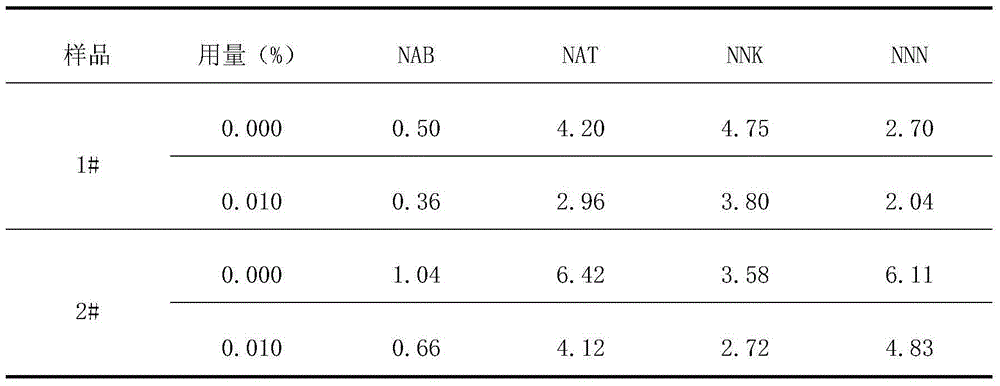

[0030] The fruit body of Boletus Luridus is crushed, dried at low temperature, water: Boletus dry powder = 2:1 (w / w), and the water temperature is maintained at 75°C for ultrasonic extraction for 2 hours; the obtained extract is concentrated and dried to obtain Boletus liver Bacteria extract extract, weigh the extract and D-glucose respectively, react at 90°C for 3 hours according to the weight ratio of 5:1, filter and concentrate into a paste, and add 0.02-2% as the raw material of e-cigarette oil.

[0031] The results show that adding an appropriate proportion of the compound flavor to the e-liquid can endow it with a special aroma, significantly increase the aroma of the smoke, and at the same time improve the sweetness and delicateness to a certain extent. The release of four specific N-nitrosamines in the flue gas also decreased significantly.

Embodiment 3

[0033]The fruit body of Boletus aereus is crushed, dried at low temperature, water: black boletus dry powder = 4:1 (w / w), the water temperature is maintained at 80°C, and the ultrasonic extraction time is 1.5h; the obtained extract is concentrated Dry to obtain the black boletus extract extract, weigh the fruiting body powder and L-sorbose respectively, react at 85°C for 4 hours according to the ratio of 8:1, filter and concentrate into a paste, and use it as one of the flavor additives according to the ratio of 0.02 to 2 The ratio of % is sprayed on shredded tobacco or tobacco sheet of electric heating type new cigarette (heating tobacco product by electric heating wire to generate smoke instead of generating smoke by lighting tobacco product) and finally shredded.

[0034] The results show that adding an appropriate proportion of the compound spices in the shredded tobacco can alcoholize the smoke, increase the aroma of the tobacco, and improve the sweetness and delicateness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com