Continuous and overall biomass pyrolysis furnace

A biomass and pyrolysis furnace technology, which is applied in the fields of biofuels, coke ovens, indirect heating and dry distillation, etc., can solve the problems of increasing the complexity of the subsequent purification mechanism and the purification difficulty, short time for efficient heat absorption, and inconvenient industrial utilization, etc. To achieve the effect of controllable pyrolysis time, clean quality, and reduced constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

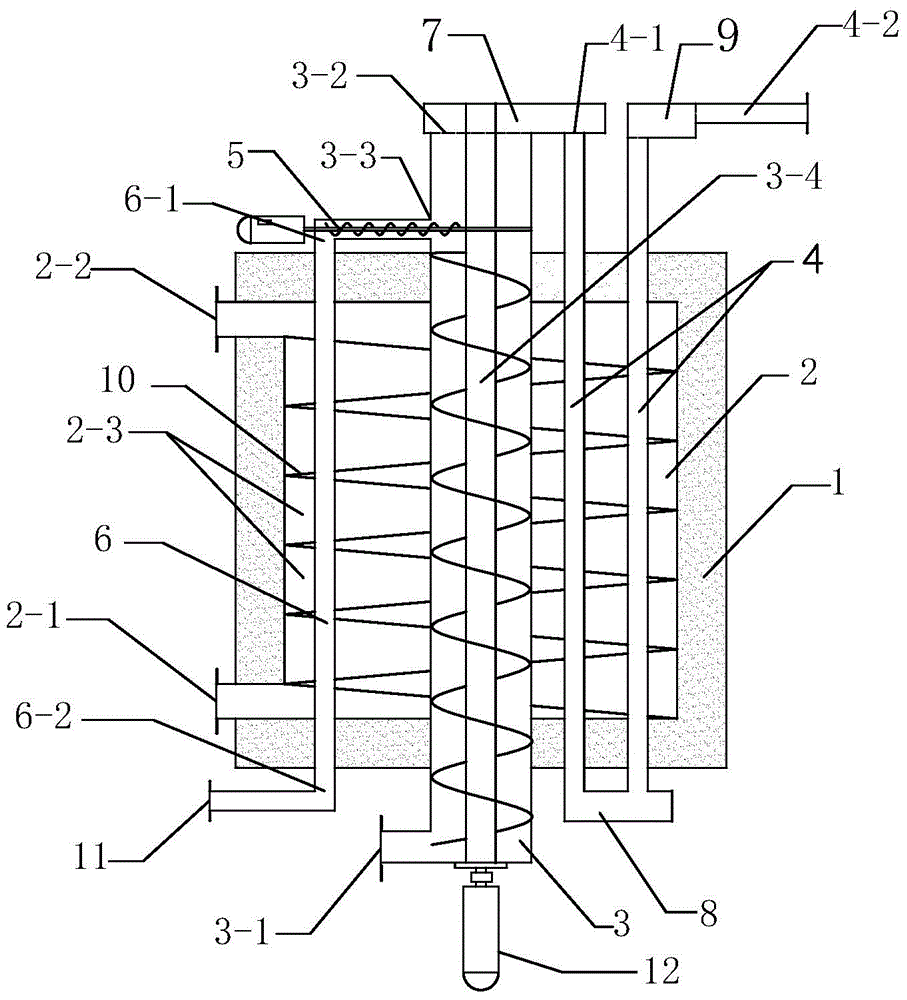

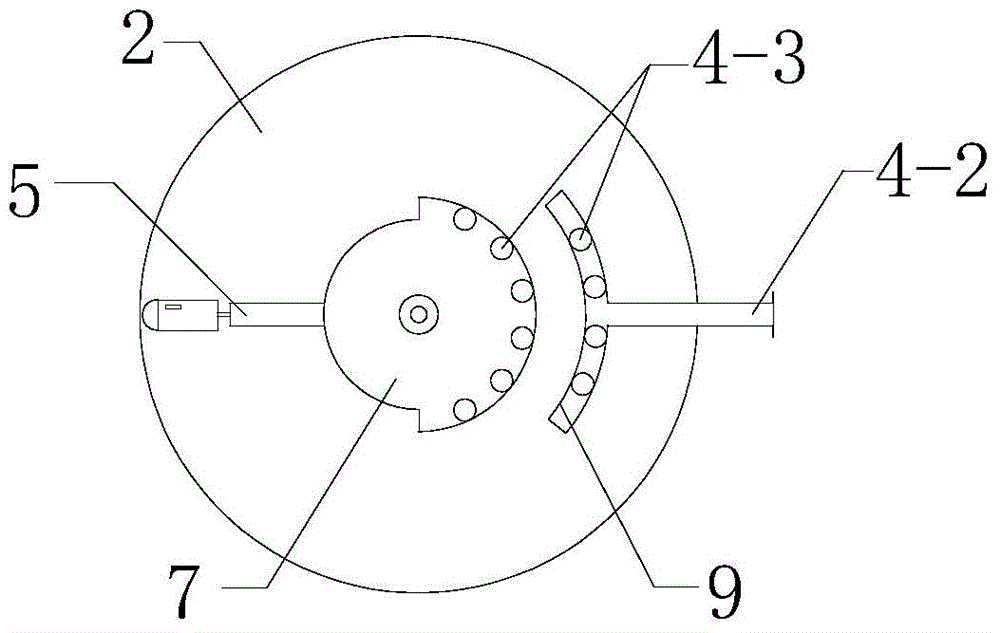

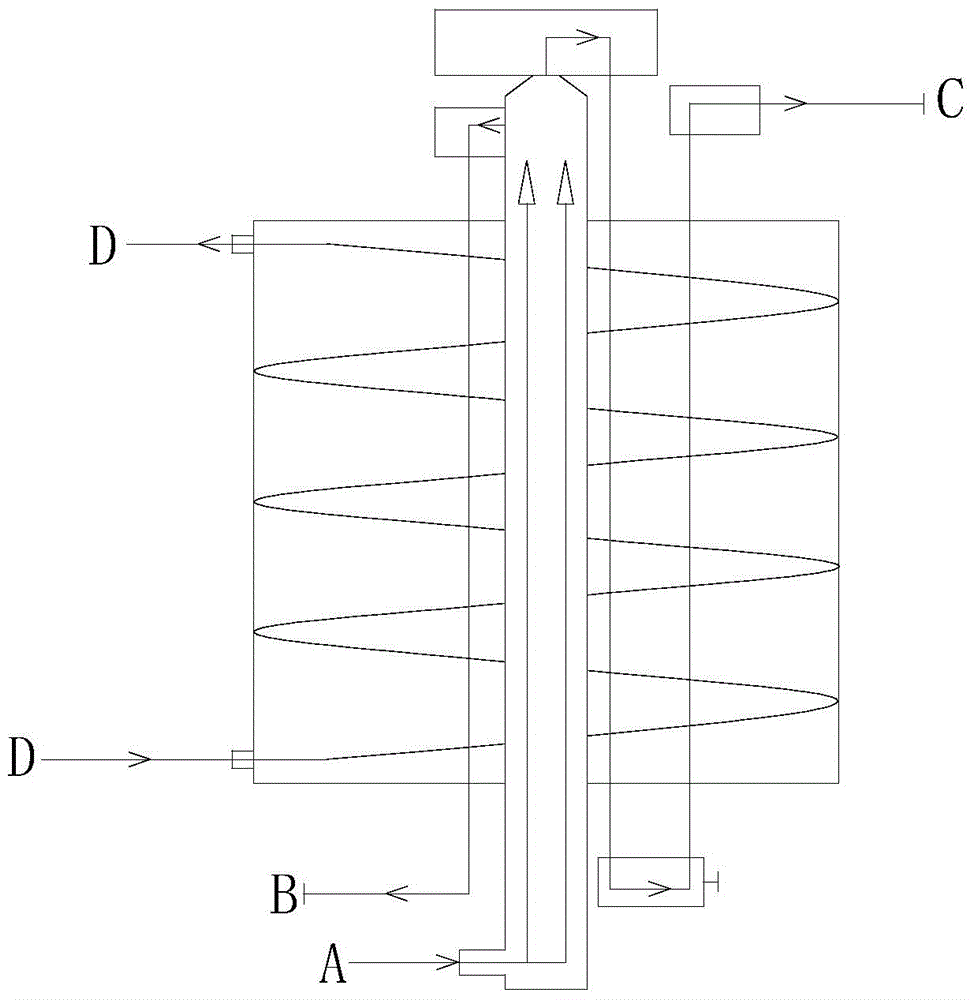

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, the biomass continuous integral pyrolysis furnace includes a thermal insulation shell 1 and a flue gas heating cavity 2 surrounded by the shell 1, and a pyrolysis chamber 3 is arranged in the flue gas heating cavity 2, which It is characterized in that: the flue gas heating chamber 2 is separated by spiral fins 10 to form a sealed spiral hot air channel 2-3 that spirals in the vertical direction, and a spiral fin 10 is provided with a vertical direction that can pass through The holes in the pyrolysis chamber 3, the pyrolysis gas tar cracking chamber 4 and the semi-coke calcining chamber 5, the spiral fins 10 are welded and fixed to the outer wall of the pyrolysis chamber 3, the pyrolysis chamber 3, the pyrolysis gas tar cracking chamber 4 and the semi-coke calcining chamber The coke calcining chamber 6 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com