Emulsification viscosity reduction agent for deep high-asphaltene super-heavy oil shaft

A technology of emulsification, viscosity reduction and asphaltenes, which is applied in the fields of organic chemistry, chemical instruments and methods, preparation of sulfuric acid ester, etc., to achieve the effects of simple production process, good economic benefits and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

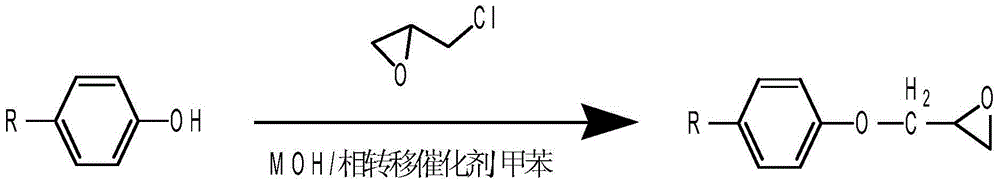

[0038] 1. Preparation of Alkylphenol Glycidyl Ether

[0039] Fix the three-neck flask with dropping funnel, thermometer and condensing reflux device in a water bath with a magnetic stirrer, add a mol of nonylphenol in sequence 0.02a~0.06a mol of phase transfer catalyst cetyltrimethylammonium bromide and tetrabutylammonium bromide complex, the compound ratio is 9:1; a~2a mol epichlorohydrin, a~ 1.5 a mol of NaOH, with toluene as solvent, magnetically stirred at 40-90°C for 4-8 hours; filter with suction, wash the filter cake with toluene, combine the organic phase, and wash the filtrate with hot water until it is neutral, and separate it with a separatory funnel. liquid and collected the organic phase, dried with anhydrous sodium sulfate, filtered, and rotary evaporated under reduced pressure to obtain a light yellow transparent liquid, that is, alkylphenol glycidyl ether.

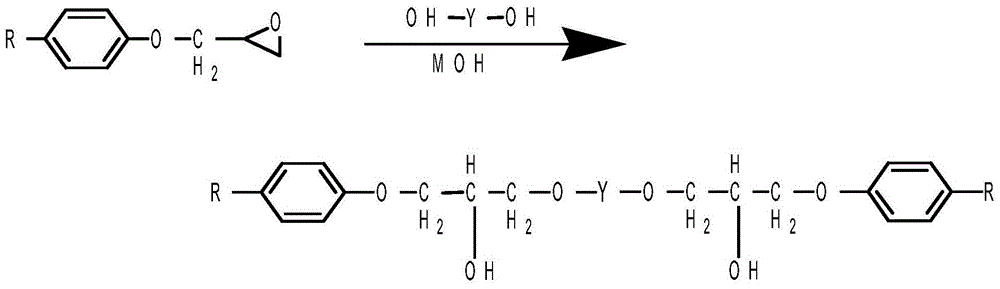

[0040] 2. Preparation of Dialkylphenol Oxypropyl Glycol Ether

[0041] Sequentially mix n mol dihydri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com