Bulk-silicon micro electromechanical system MEMS structure front surface subsequent processing method

A micro-electro-mechanical system and process technology, applied in the direction of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of low product qualification rate and easy damage of suspended structures, so as to strengthen the suspended structure, facilitate product design and Typesetting, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

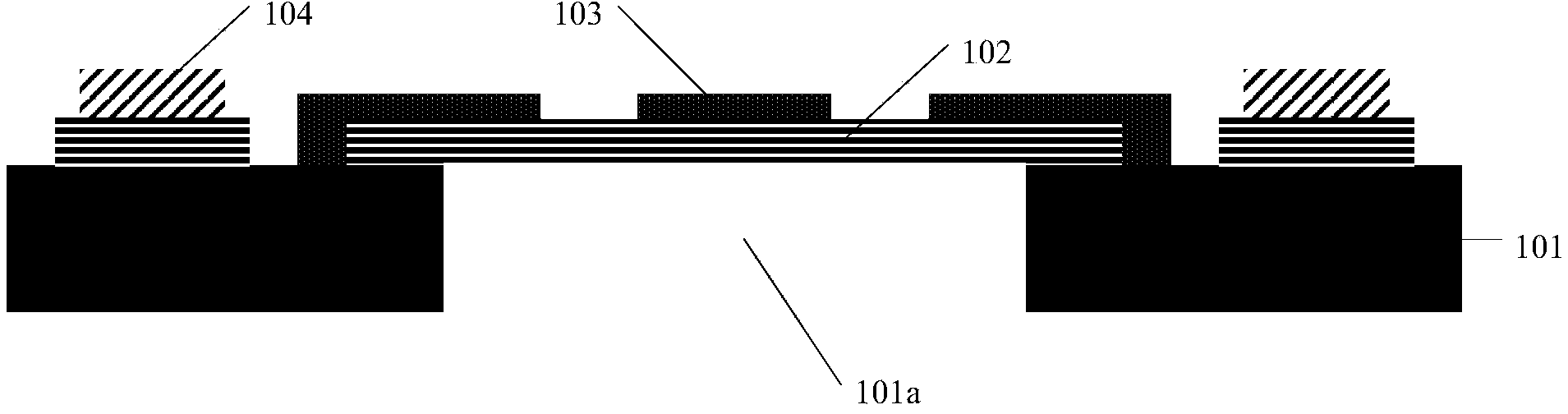

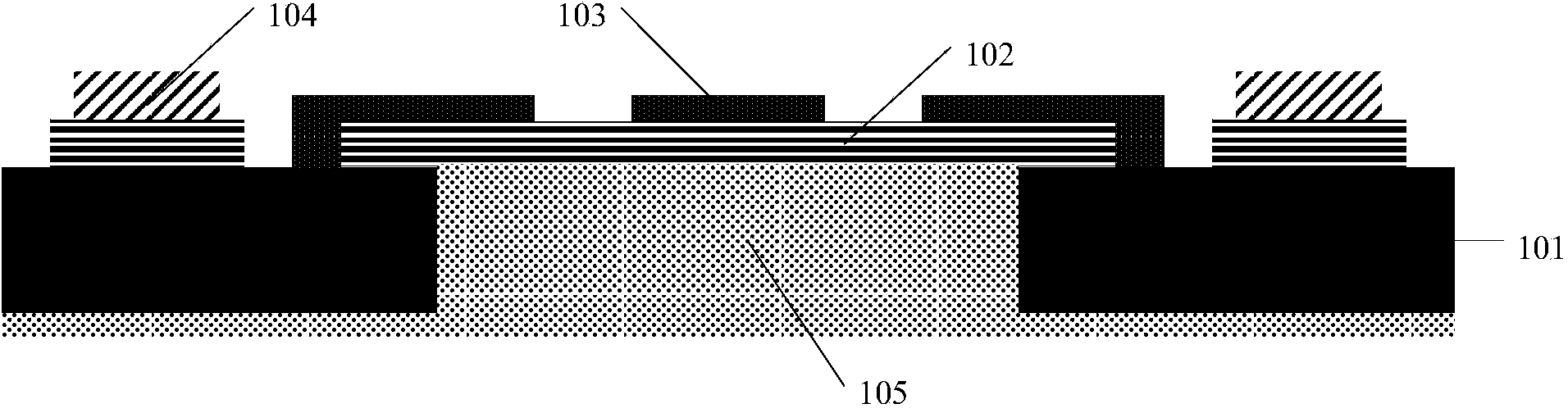

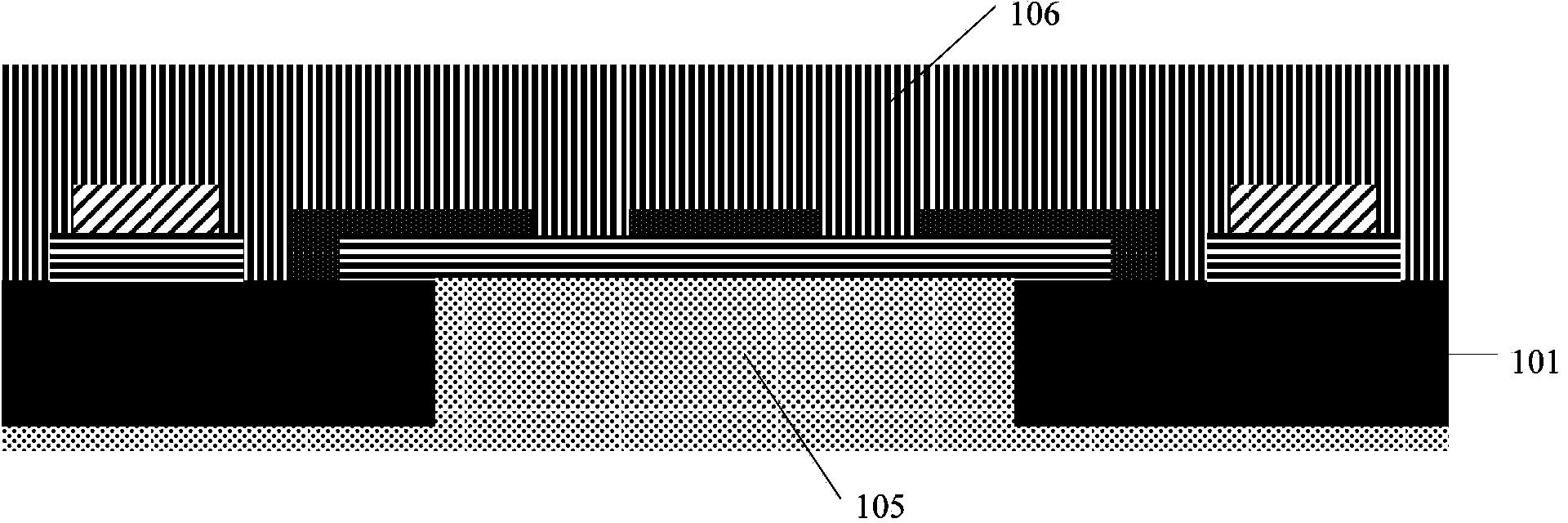

[0024] Please refer to Figure 1A ~ Figure 1G , is a cross-sectional schematic diagram of the front-side process method of the bulk silicon micro-electromechanical system MEMS structure according to Embodiment 1 of the present invention.

[0025] In this embodiment, specific circuits on the front side of the silicon chip need to be protected, and only the area to be released is exposed. This embodiment adopts the method of photoresist protective layer.

[0026] First, please refer to Figure 1A A typical bulk silicon MEMS structure is shown. Deep grooves 101a are etched from the backside of the silicon wafer 101 . From top to bottom, the front side of the silicon chip is a MEMS support and functional layer 103, and a sacrificial layer 102 between the MEMS support and functional layer 103 and the deep groove 101a. The periphery of the MEMS support and functional layer 103 is a circuit part 104, and its height is slightly above the MEMS support and functional layer 103 .

...

Embodiment 2

[0036] Please refer to Figure 2A ~ Figure 2K , is a schematic cross-sectional view of the front-side process method of the bulk silicon MEMS structure according to Embodiment 2 of the present invention.

[0037] In this embodiment, a dielectric protection layer needs to be deposited on a specific line on the front side of the silicon wafer, so as to prevent further corrosion of the protected area by the release of chemical solution or reaction gas when the sacrificial layer is released.

[0038] Figure 2A It is a typical bulk silicon MEMS structure. Deep trenches 201a are etched from the backside of the silicon wafer 201 . The front side of the silicon chip is MEMS support and functional layer 203 from top to bottom, and the sacrificial layer 202 between MEMS support and functional layer 203 and deep groove 201a, and the periphery of MEMS support and functional layer 203 is circuit part 204, and its height is slightly above the MEMS support and functional layer 203 .

[...

Embodiment 3

[0048] In some applications, the thin film 207 of the second embodiment is not a dielectric protection layer, but a component of a specific circuit necessary to realize a certain function. Therefore complete the example shown in the second example Figure 2A ~ Figure 2F The steps in the above step only complete the deposition and patterning of the specific circuit, and it is necessary to continue to use the photoresist protection layer to protect the specific circuit formed in the second embodiment from being damaged when the sacrificial layer is subsequently released. Embodiment 3 provides the operation method in the above situation.

[0049] Similar to the structure shown in the second embodiment, the thin film 207 is an integral part of a specific circuit necessary to realize a certain function. After the deposition and patterning of the dielectric layer 207 on the front side of the silicon wafer 201 is completed, it needs to be protected, and only the area on the front si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com