Grain warehousing device for combine harvester

A combine harvester and grain technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of low harvest rate, impure grains, and easily broken grains, so as to overcome the low harvest rate and improve the purity. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

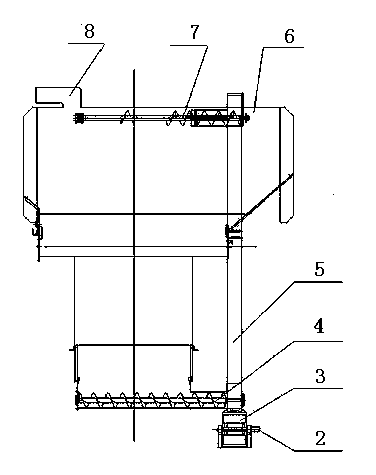

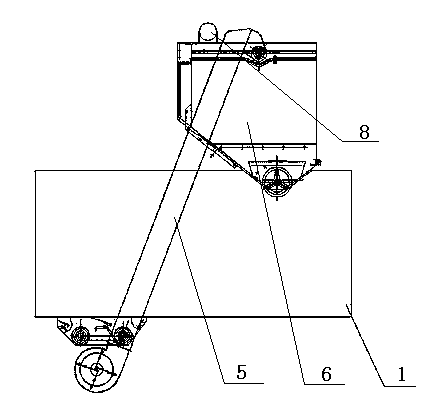

[0008] figure 1 , figure 2 The grain entering bin device of the combine harvester of the present invention shown is that the particle auger 4 is set at the bottom of the frame 1, and the particle distribution propeller 7 is set in the granary 6, between the particle auger 4 and the particle distribution propeller 7 An inclined particle elevator 5 is arranged between them, and the particle elevator 5 is a hollow cylinder. At the grain grain outlet of the particle auger 4 corresponding to the particle elevator 5, a hydraulic pressure is set at the bottom of the particle elevator 5. The fan 3 driven by the motor 2. In addition, a dust outlet 8 is established at the top of the granary 6 .

[0009] During the work of the present invention, the threshed grain grain enters the device from the entrance of the particle auger 4 at the bottom of the frame 1, and is driven by the particle auger 4 to the outlet. 4. Under the action of the outlet fan 3 wind (the wind force can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com