Megawatt corrugated waveguide attenuator

A corrugated waveguide and attenuator technology, which is applied in the field of megawatt-level corrugated waveguide attenuators, can solve the problems of large water load cavity, inconvenient installation and debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

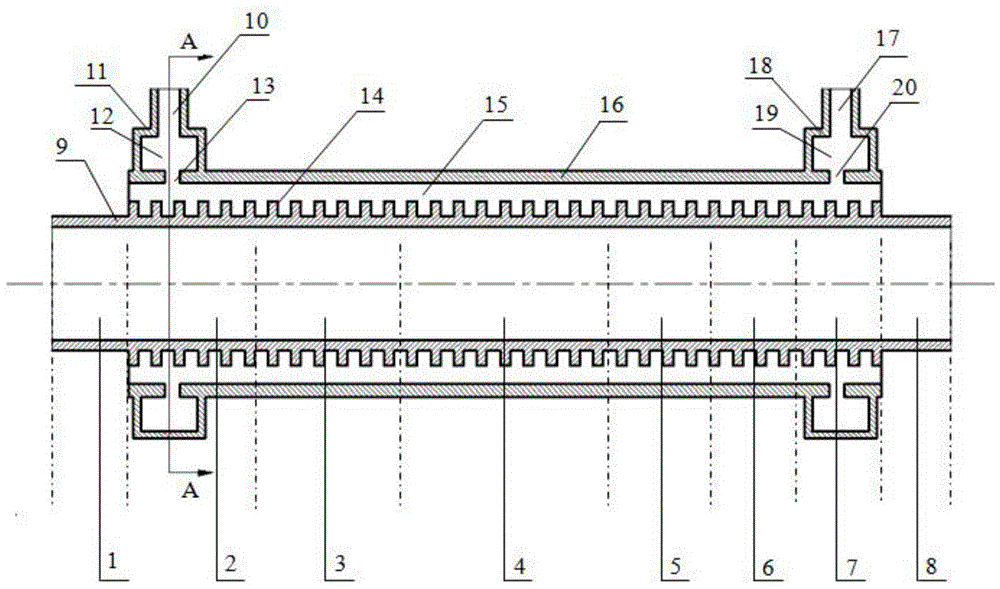

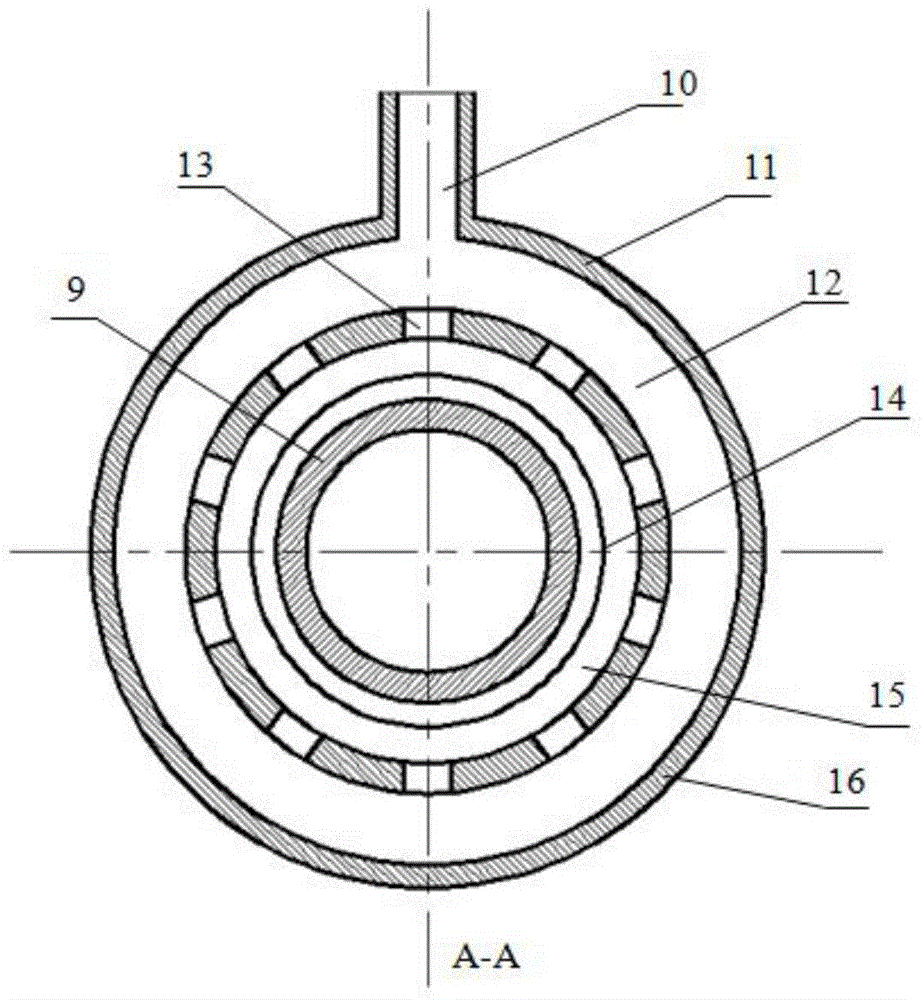

[0014] Such as figure 1 , 2 As shown, a megawatt-level corrugated waveguide attenuator includes a circular waveguide 9, on which a standard corrugated waveguide section supporting HE11 mode transmission is sequentially arranged. Smooth waveguide section 2 for mode conversion 2. Mode-changing waveguide section 3 for realizing conversion from TE11 and TM11 mixed mode to EH11 mode 3. Main attenuation waveguide section 4 for power attenuation 4. Realize conversion from EH11 mode to TE11 mode in residual power Mode-changing waveguide section 5 5, smooth waveguide section 6 for TE11 mode transmission, 6, mode-changing waveguide section 7 for realizing TE11 mode to HE11 mode conversion, and standard corrugated waveguide section 8 8 supporting HE11 mode transmission, in waveguide 9 Periodic grooves 14 are distributed on the outer wall, and a circular metal water jacket 16 is set on the periphery of the entire waveguide 13 to form a circular water channel 15. There are twelve grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com