Liquid negative electrode glow discharge atomizer

A technology of atomizer and glow discharge, which is applied in the field of atomic spectroscopic analysis, can solve problems affecting experimental efficiency, liquid level fluctuations, test signal fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

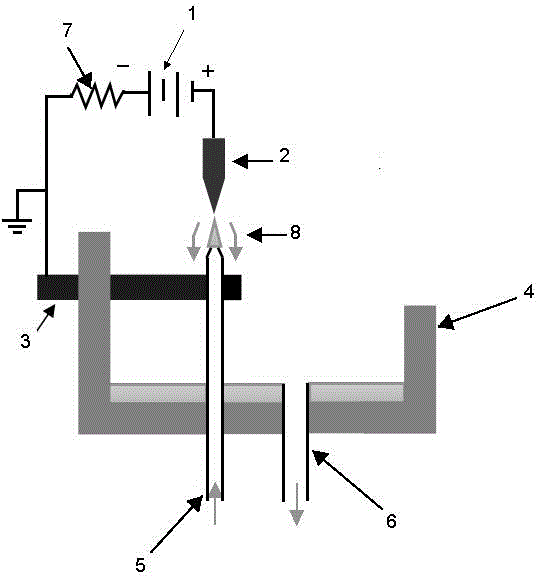

[0048] figure 1 Schematic diagram of the structure of the liquid cathode glow discharge atomizer claimed for protection in this application. As shown in the figure, power supply 1 adopts BHK2000-0.1MG high-voltage source to provide 0-2000V DC high voltage, and the rated current is 0.1A. The wire from the positive pole of the high voltage source 1 is connected to the tungsten electrode 2 through the protection resistor 7; the negative pole is connected to the graphite rod 3. The sample solution overflows from the sampling tube 5 through the peristaltic pump, and constitutes the entire circuit of the glow device together with the graphite rod 3 and the peripheral circuit. The top of the sampling tube 5 is kept at a distance of 2-4 mm from the tip of the metal anode 2; the electrolyte solution therein can be one of nitric acid, hydrochloric acid, and sulfuric acid, and the pH needs to be adjusted to 1. The designed liquid pool is made of polytetrafluoroethylene material through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com