Close-fitted heat radiation fin and heat pipe structure

A technology of heat dissipation fins and heat pipes, which is applied in the combined application field of heat dissipation fins and heat pipes, and can solve the problem that heat dissipation fins and heat pipes cannot achieve urgent combination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

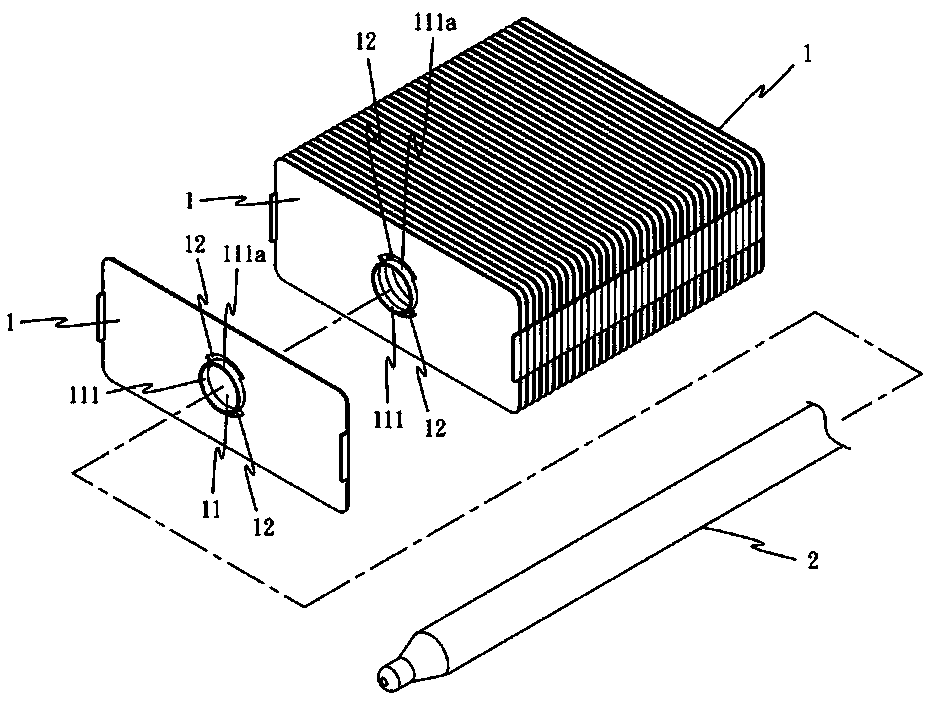

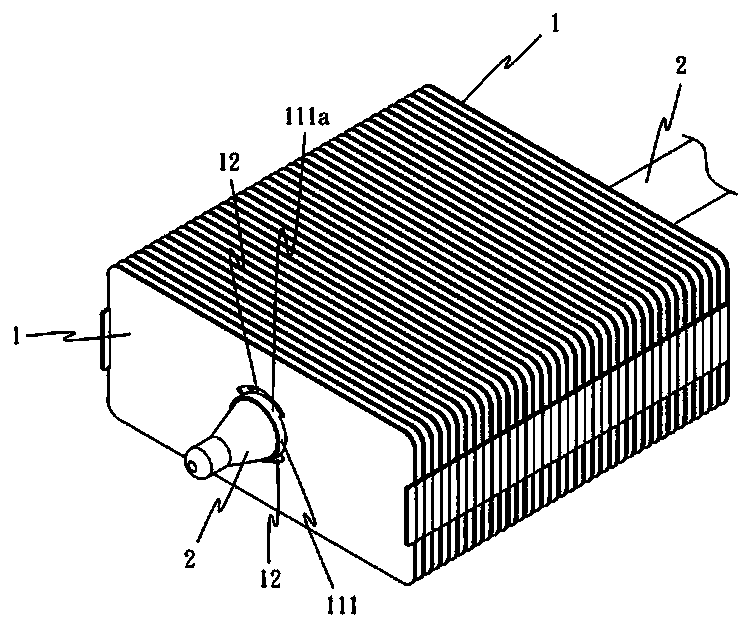

[0035] Such as Figure 1 to Figure 5 As shown, it shows the specific structure of the present invention, which mainly includes a plurality of cooling fins 1 and a heat pipe 2, and wherein:

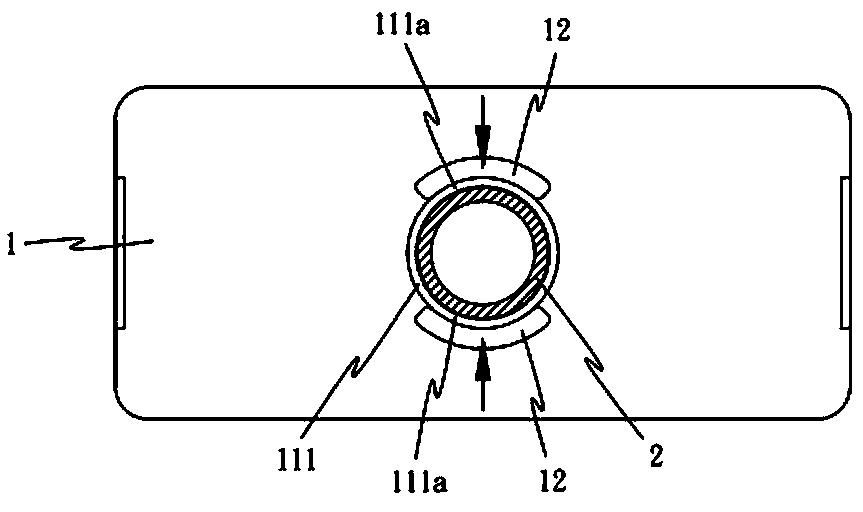

[0036] A plurality of cooling fins 1 are arranged in series, and each cooling fin 1 is provided with at least one through hole 11, and the through hole 11 has an extended protruding ring 111, and the protruding ring 111 is provided with an adjoining one on both symmetrical sides. The arc-shaped hole 12 separates the partial ring walls 111 a on both sides of the protruding ring 111 from the main body of the cooling fin 1 .

[0037] The heat pipe 2 runs through the through holes 11 of the series-parallel heat dissipation fins 1 .

[0038] Utilize above-mentioned plural heat dissipation fins 1 and heat pipe 2, system heat pipe 2 runs through the through hole 11 of heat dissipation fin 1 (such as figure 2 and image 3 ), and then stamp the local ring walls 111a on both sides of the convex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com