Tubular specimen constant deformation stress corrosion test fixture

A deformation stress and corrosion test technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inconvenient handling and placement, expensive equipment, and sample deformation, so as to save materials and laboratory equipment resources , low cost, and simple fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

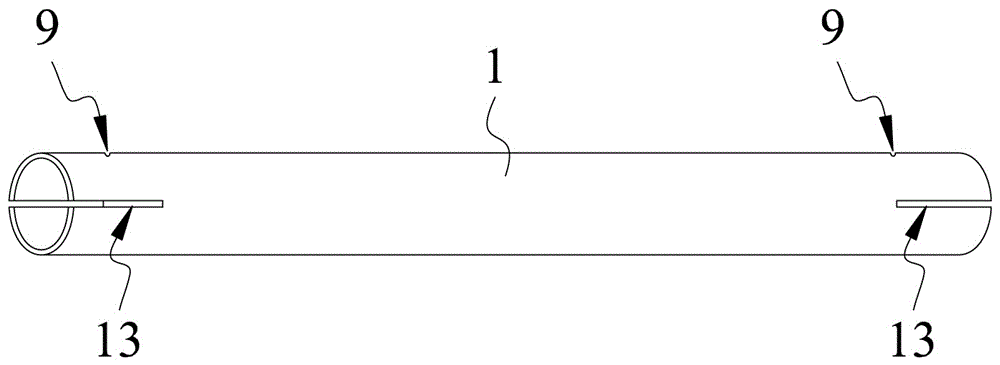

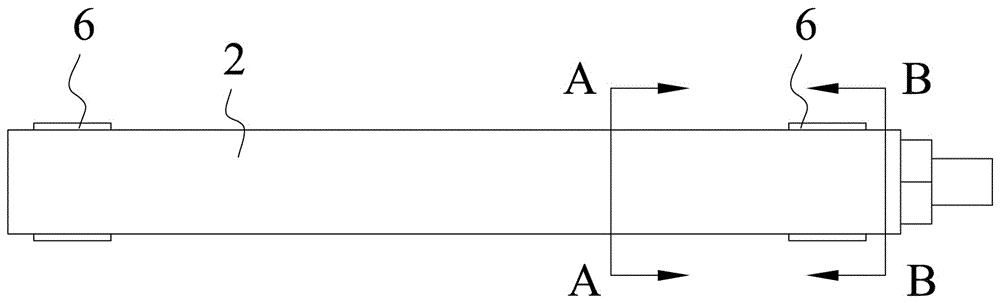

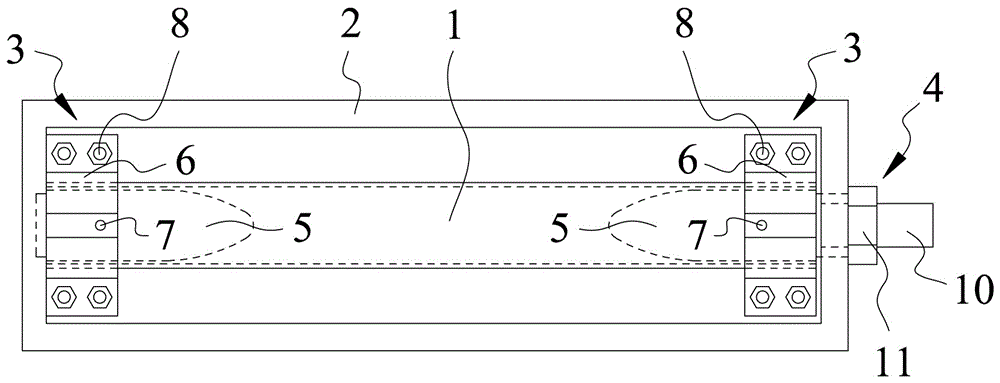

[0022] Embodiment one: see attached figure 1 To attach Figure 5 As shown, a tubular sample constant deformation stress corrosion test fixture for fixing a tubular sample 1 to be tested and performing a constant deformation stress corrosion test includes a bracket 2 , two sets of positioning components 3 and a force applying component 4 .

[0023] The support 2 is in the shape of a rectangular frame, and the tubular sample 1 to be tested is arranged in it along the length direction of the support 2 . Specifically, each set of positioning components 3 includes a positioning stem 5 , a positioning hoop 6 , a connecting piece 7 and a locking piece 8 . as attached Figure 6 And attached Figure 7 As shown, the positioning stem 5 includes one end inserted into the end of the tubular sample 1 and one end located outside the end of the tubular sample 1 . Among them, the end inserted into the tubular sample 1 has a longer length and a circular cross-section, and at least a part th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com