Asbestos-free micro-metal polycrystalline fiber automotive drum brake linings

A drum brake, asbestos-free technology, applied in the direction of brake parts, chemical instruments and methods, and other chemical processes, can solve the problems of high product hardness, harm to human health, injury to the couple, etc., to achieve stable friction coefficient, brake Sensitive, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

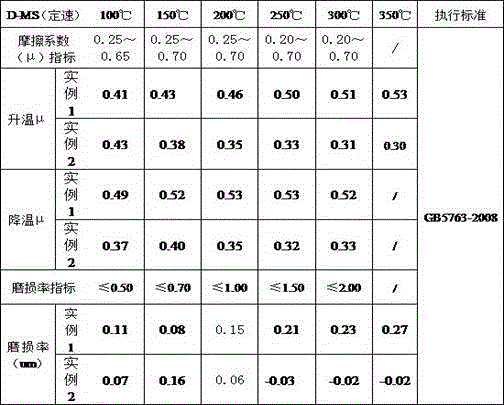

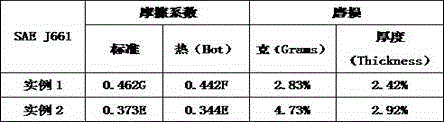

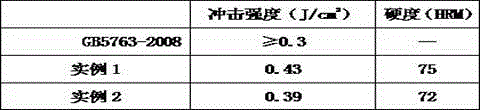

[0055] Explanation: Under the condition that the production process, equipment and process parameters are exactly the same, the thickness of the product is 15mm as an example, and two sets of tests are carried out. The amount of raw materials is exactly the same except for polycrystalline mullite fiber and ordinary refractory fiber. Example Add polycrystalline mullite fiber in 1, add ordinary refractory fiber (that is, glass fiber, which is a kind of reinforcing material, and use the product produced by Danyang Zhenxing Glass Fiber Co., Ltd.) in Example 2, and conduct a comparative test. The specific data is shown in Table 2) ; Process method of the present invention: first weigh various raw materials according to the ratio of raw materials stipulated in the formula, and premix the materials in steps.

[0056] 1) Ingredients

[0057] Premix one: according to the ratio of raw materials in Example 1 or Example 2 (see Table 2 for specific values), weigh zinc stearate and the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com