Automatic guide part conveying device

A conveying device and automatic guidance technology, which is applied in the direction of power devices, transportation and packaging, and motor vehicles, can solve the problems of increased turning distance, unfavorable parts transportation, and high requirements for the range of motion, so as to reduce driving pressure and reduce selection. The effect of requesting and increasing the scope of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

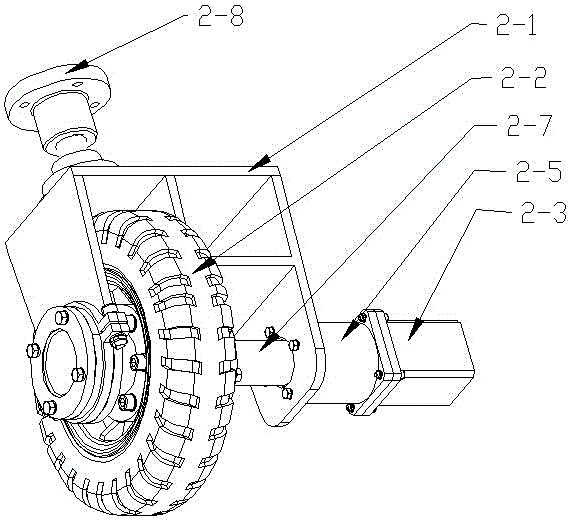

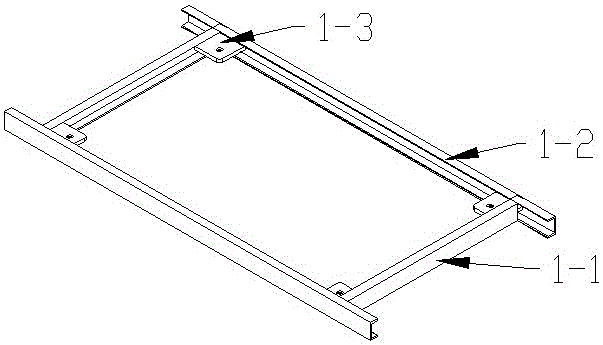

[0031] An automatic guided parts conveying device, including a drive system, an anti-collision system, a power supply system, a frame chassis 1 and a central control 4; the drive system controls the operating state through the central control 4 to ensure the smooth operation of the device, including four independent The drive unit 2 and the drive frame chassis 1; the drive unit 2 is provided with a motor, which can complete steering and driving alone, and drives the frame chassis 1 to complete parts delivery; the power supply system includes a battery slot 3, through the battery slot 3 The battery provides power; the anti-collision system includes a mechanical anti-collision system 5, which controls the motor deceleration anti-collision or the mechanical anti-collision system 5 in the drive unit 2 to avoid obstacles automatically through the central control 4.

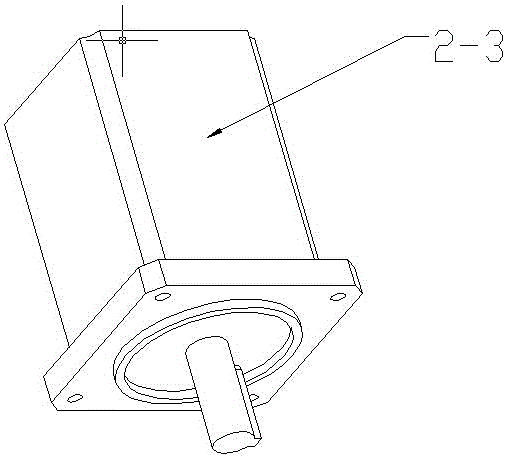

[0032] The drive unit 2 is composed of a drive motor 2-3, a steering motor 2-4, a steering reducer 2-6, a steering co...

Embodiment 2

[0035] An automatic guided parts conveying device, including a drive system, an anti-collision system, a power supply system, a frame chassis 1 and a central control 4; the drive system controls the operating state through the central control 4 to ensure the smooth operation of the device, including four independent The drive unit 2 and the drive frame chassis 1; the drive unit 2 is provided with a motor, which can complete steering and driving alone, and drives the frame chassis 1 to complete parts delivery; the power supply system includes a battery slot 3, through the battery slot 3 The battery provides power; the anti-collision system includes a mechanical anti-collision system 5, which controls the motor deceleration anti-collision or the mechanical anti-collision system 5 in the drive unit 2 to avoid obstacles automatically through the central control 4.

[0036] Described mechanical anti-collision system is made up of anti-collision system sensor 5-1, anti-collision plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com